11

■

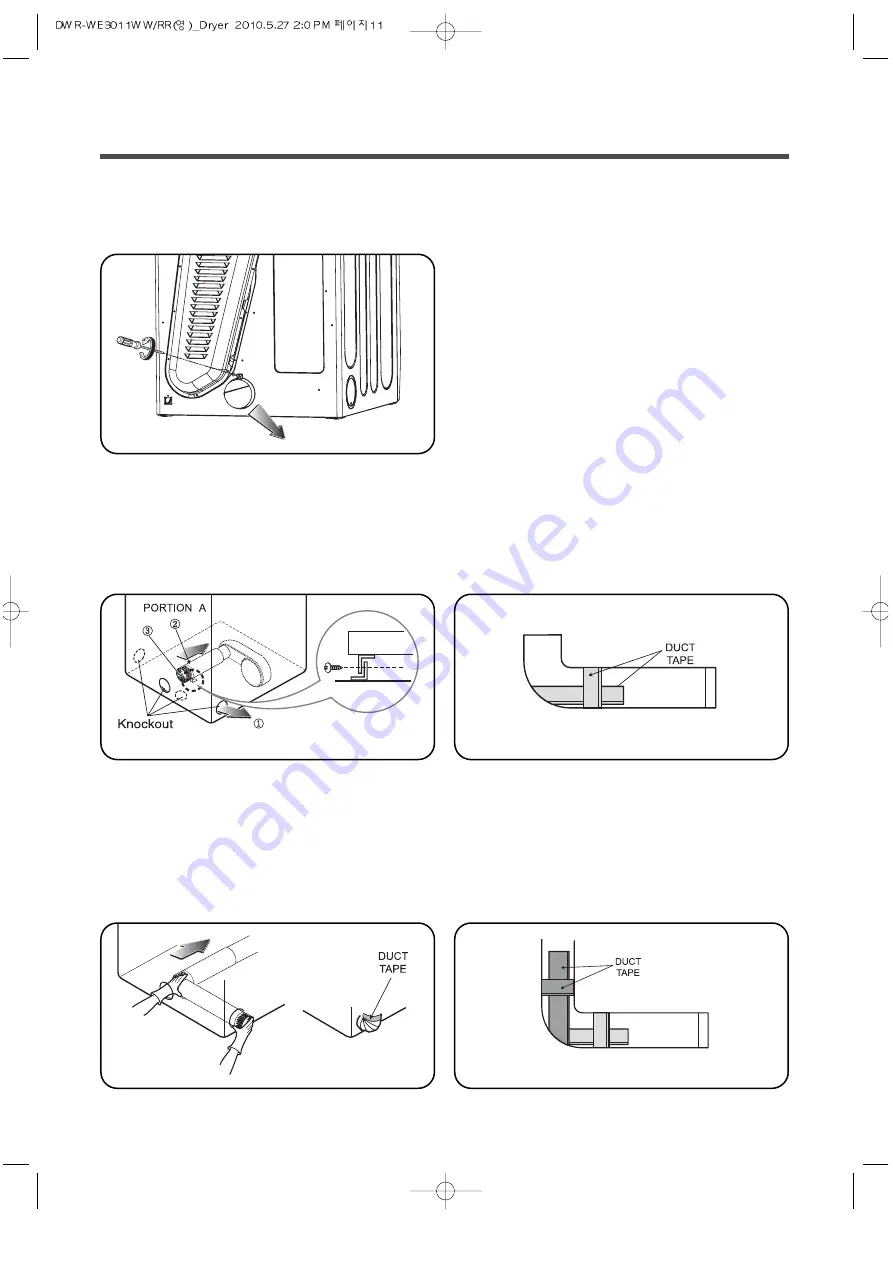

ALTERNATE EXHAUST DIRECTIONS

1. Remove screw and exhaust duct.

2-1. Detach and remove the knockout that

matches the desired venting direction

(Right side not available on Gas Dryers)

2-2. Reconnect the new duct[8.66 inch(22cm)]

to the blower housing, and fixing the duct

to the base.

3-1. Insert the male end of a 4" elbow into the

female end of a short duct. Tape the joint.

3-2. Insert this assembly elbow first through

the hole in the dryer and push the female

end of the elbow onto the male end of the

blower output shaft. Tape the joint.