22

4.

MECHANICAL ADJUSTMENT

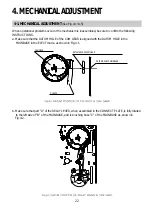

4-1. MECHANICAL ADJUSTMENT

(See Fig.4-1~4-5)

When operational problems occur or the mechanism is reassembled, be sure to confirm the following

INSTRUCTIONS.

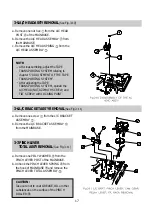

a. Make sure that the DATUM HOLE of the CAM GEAR is aligned with the DATUM HOLE in the

MAINBASE in the EJECT mode, as shown in Fig.4-1.

b. Make sure that part "A" of the RELAY LEVER, when assembled in the CONNECT PLATE, is fully rotated

to the left side of "B" of the MAINBASE, and is touching boss "C" of the MAINBASE as, shown in

Fig.4-2.

CAM GEAR

F/L RACK

DATUM HOLE OF CAM GEAR

DATUM HOLE OF MAIN BASE

Summary of Contents for GB14H3

Page 5: ...4 CIRCUIT BLOCK DIAGRAM ...

Page 12: ... 11 SCHEMATIC DIAGRAM ...

Page 13: ... 12 SCHEMATIC DIAGRAM ...

Page 14: ...13 EXPLODED VIEW 1 14H3 ...

Page 15: ...14 EXPLODED VIEW 2 14H4 ...

Page 16: ...15 EXPLODED VIEW 3 20H3 ...

Page 17: ...16 EXPLODED VIEW 4 20H4 ...

Page 18: ...17 EXPLODED VIEW 5 21H4 ...

Page 19: ......

Page 20: ......

Page 58: ...3 1 2 1 WIRE DIAGRAM 1 2WIREDIAGRAM ...

Page 62: ...7 2 1 2 PARTS LOCATION OF FRONT LOADING ASS Y A TOP VIEW B FRONT VIEW ...

Page 92: ...37 6 EXPLODEDVIEWANDPARTSLIST 6 1 EXPLODEDVIEWOFDECKASS Y TOPVIEW ...

Page 93: ...38 6 2 EXPLODEDVIEWOFDECKASS Y BOTTOMVIEW ...

Page 94: ...39 6 3 EXPLODEDVIEWOFF LASS Y ...

Page 95: ...40 ...