28

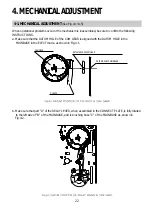

Fig. 5-1 THE SCHEMATIC DIAGRAM OF TAPE TRANSPORTING SYSTEM

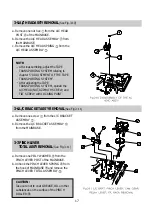

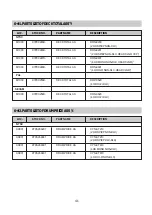

When the parts as shown in Fig. 5-1 are replaced, the TAPE TRANSPORTING SYSTEM has changed. To

prevent this, it is essential to know thoroughly and observe the following INSTRUCTIONS.

A. ADJUSTMENT OF THE S/T GUIDE ROLLER

a. Play back a T-120 TAPE.

b. Make sure that excessive TAPE wrinkle does not occur at each S/T GUIDE ROLLER.

c. If TAPE wrinkle is observed at the S/T GUIDE ROLLER, adjust them so that no wrinkle occurs.

Summary of Contents for GB14H3

Page 5: ...4 CIRCUIT BLOCK DIAGRAM ...

Page 12: ... 11 SCHEMATIC DIAGRAM ...

Page 13: ... 12 SCHEMATIC DIAGRAM ...

Page 14: ...13 EXPLODED VIEW 1 14H3 ...

Page 15: ...14 EXPLODED VIEW 2 14H4 ...

Page 16: ...15 EXPLODED VIEW 3 20H3 ...

Page 17: ...16 EXPLODED VIEW 4 20H4 ...

Page 18: ...17 EXPLODED VIEW 5 21H4 ...

Page 19: ......

Page 20: ......

Page 58: ...3 1 2 1 WIRE DIAGRAM 1 2WIREDIAGRAM ...

Page 62: ...7 2 1 2 PARTS LOCATION OF FRONT LOADING ASS Y A TOP VIEW B FRONT VIEW ...

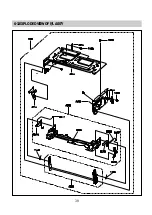

Page 92: ...37 6 EXPLODEDVIEWANDPARTSLIST 6 1 EXPLODEDVIEWOFDECKASS Y TOPVIEW ...

Page 93: ...38 6 2 EXPLODEDVIEWOFDECKASS Y BOTTOMVIEW ...

Page 94: ...39 6 3 EXPLODEDVIEWOFF LASS Y ...

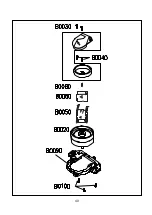

Page 95: ...40 ...