Hydraulic System

Relief Valve Pressure Check

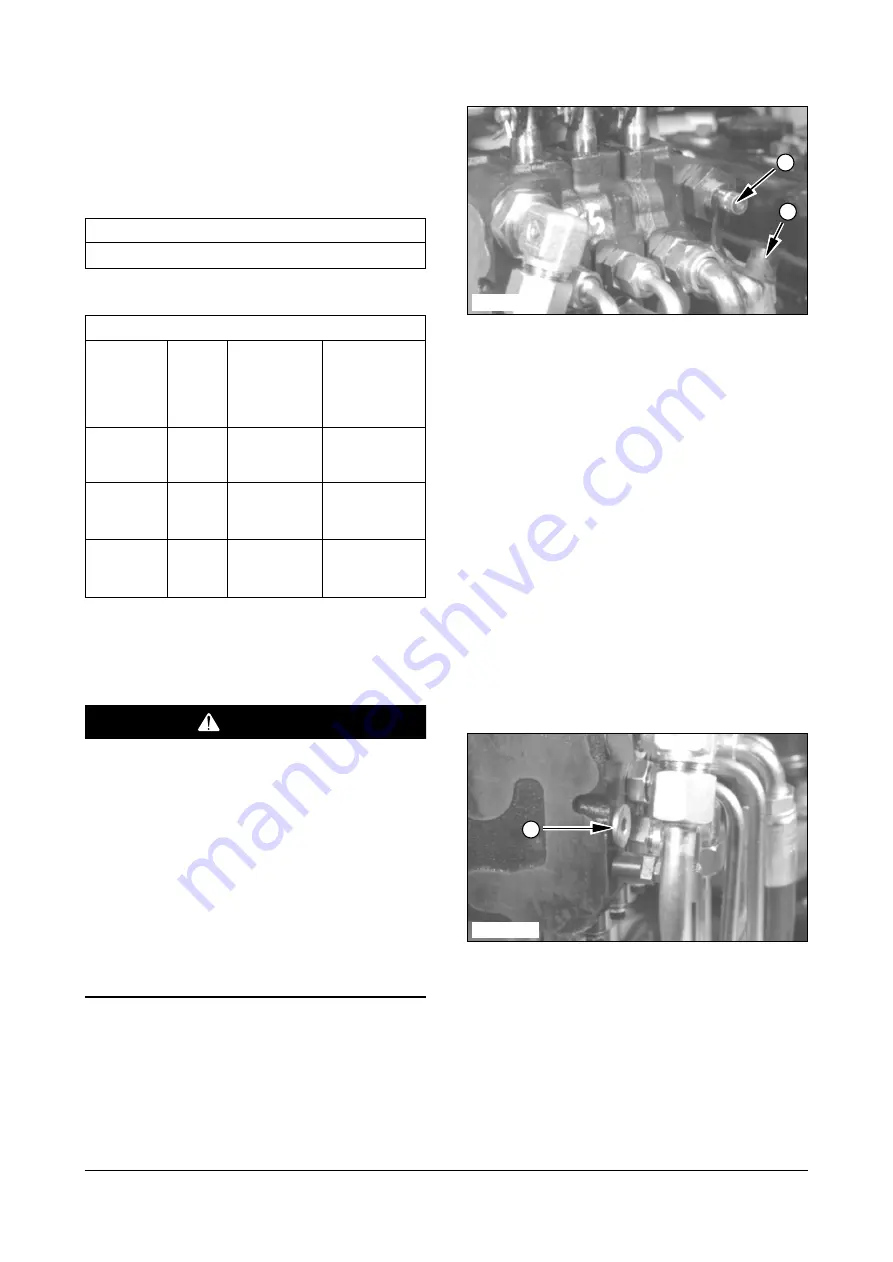

Use the Fittings Group to check the relief valve

pressure.

Pressure Tap Location

(1) Cap. (2) Nipple assembly.

With the engine off, remove cap (1) from nipple

assembly (2) and connect the 28,000 kPa (4000 psi)

gauge to the nipple assembly.

Lift Relief Valve Check and Adjustment

1. Start the engine and activate the hydraulics until

the hydraulic oil is at the normal operating

temperature. Tilt the mast back to the end of its

travel.

2. With the engine at high idle, hold the tilt control

lever in the tilt back position and watch the gauge.

The gauge indication is the pressure that opens

the relief valve.

3. The correct pressure setting is shown in the chart.

Relief Valve Adjustment.

(3) Plug.

23 of 29

New Hydraulic Systems

Testing and Adjusting

Tools Needed

Fittings Group

CONTROL VALVE

Tilt, Auxiliary

Relief Valve

Pressure

°æ 350 kPa

(°æ 50 psi)

15,500 (2250)

15,500 (2250)

15,500 (2250)

Main Relief

Valve

Pressure

°æ 500 kPa

(°æ 75 psi)

18,100 (2625)

19,500 (2825)

21,550 (3125)

Mast

Std

FFL

FFTL

Std

FFL

FFTL

Std

FFL

FFTL

Model

D(G)20(S)

GC20(S)

D(G)25(S)

GC25(S)

D(G)30S

GC30S

WARNING

Hydraulic oil, under pressure can remain in the

hydraulic system after the engine and pump have

been stopped. Personal injury can be caused if this

pressure is not released before any work is done on

the hydraulic system. To prevent possible injury,

lower the carriage to the ground, turn the engine off

and move the control levers to make sure all

hydraulic pressure is released before any fitting,

plug, hose or component is loosened, tightened,

removed or adjusted. Always move the lift truck to a

clean and level location away from the travel of

other machines. Be sure that other personnel are

not near the machine when the engine is running

and tests or adjustments are made.

IDCS001C

IDCS002C

2

1

3

Summary of Contents for D20S-2

Page 8: ......

Page 13: ......

Page 24: ...27 of 29 New Hydraulic Systems Disassembly and Assembly IDCS015B...