14

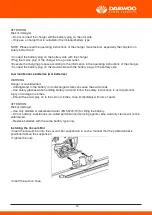

Cleaning the floater

• Open the cover of the waste water tank.

•

Pull out the float casing towards the top.

•

Detach locking hooks.

•

Clean float and bottom part.

•

Assemble the float casing and insert it into the device.

16. ACCESSORIES

17. TECHNICAL SPECIFICATIONS

Power

Battery: 24V/ 100 Ah

Average power consumption: 1000 W

Power suction turbine: 500 W

Power brush drive: 500 W

Max running time: 5 h

Vacuuming

Vacuum power, air volume (max.): 24 L/s

Vacuuming power, negative pressure (max.): 120 kPA (mbar)

Cleaning brushes

Brush speed: 175 rpm

Brush diameter: 510 mm

Dimensions and weights

Theoretical surface cleaning performance: 2000 m²/h

Suction width: 850 mm

Cleaning width: 510 mm

Max. working range incline: 2%

Fresh/ waste water tank volume: 50/ 50 L

Max. water temperature 60°C

Ambient temperature 5 - 40°C

Net weight 160 kg

Dimensions of battery compartment: 350 x 350 mm

Values determined as per EN60335-2-72

Total oscillation value: < 2.5 m/s²

Uncertainty K: 0.2 m/s²

Sound pressure level Lpa: 66 dB(A)

Uncertainty Kpa: 2 dB(A)

Sound power level Lwa +: 81 dB(A)

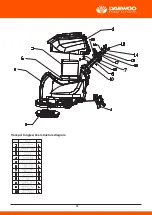

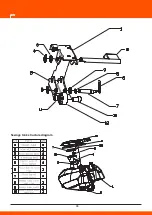

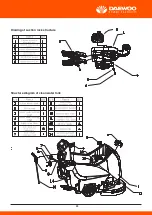

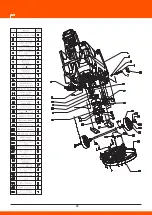

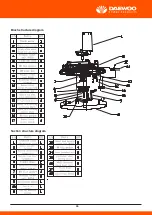

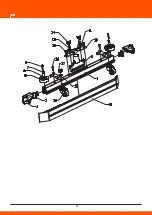

18. EXPLODED VIEW AND SPARE PARTS LISTS

Vehicle structure diagram

• Remove the batteries.

• Dispose of the used batteries according to the local provisions.

Maintenance contract

To ensure a reliable operation of the appliance maintenance contracts can be concluded with the compe-

tent sales office.

14. FROST PROTECTION

In case of danger of frost:

• Empty the fresh and waste water tank.

• Store the appliance in a frost-protected room.

15. FAULTS

DANGER

Risk of injury! Set the programme selector switch to "OFF" and pull the mains plug of

the charger prior to performing any work on the appliance.

Remove the battery plug from machine.

• Drain and dispose of the dirt water and the residual fresh water.

Faults without display on the console

2 Transport chassis pedal in cleaningposition

• Using your foot, move the transport chassis pedal to the required position.

Cleaning

ATTENTION

Risk of damage to the floor covering. Do not operate the appliance on the spot.

• Swivel the transport chassis to the cleaning position.

• Turn the program selection switch to the desired cleaning program.

Lower the vacuum bar

• Pull the lever out and press it down; the vacuum bar is lowered.

NOTE:

– For cleaning tiled floors, adjust the straight suction bar in such a way that cleaning is not done at an

angle of 90 degrees to the joints.

– The inclined position and the inclination of the suction bar can be adjusted to achieve better suction

results (see"Adjusting the suction bar").

– If the waste water tank is full, the float closes the suction opening and the suction

turbine runs at an increased speed.

If this is the case, shut the vacuum off and drive to empty the waste water tank.

10. SHUTTING DOWN THE APPLIANCE

• Close the regulatory button for setting the water quantity.

• Release the safety switch.

• Set the program selection switch to suction or vacuuming.

• Briefly drive forward and suck of the remaining water.

• Raise the vacuum bar.

• Swivel the transport chassis to the transport position.

• Charge battery, if required.

Drain off dirt water

WARNING

Please observe the local provisions regarding the wastewater treatment.

• Take the water discharge hose from the support and lower above a suited collection device.

• Open the lid of the dosing equipment.

• Drain off the dirt water - regulate the water quantity by pressing or bending.

• Rinse the waste water tank with clear water.

Drain off cleanwater

• Unscrew the lock of the fresh water reservoir.

11. TRANSPORT

DANGER

Risk of injury! When loading or unloading the machine, it may only be operated on gradients up to the

maximum value (see "Technical Specifications"). Drive slowly.

CAUTION

Riskof personal injury or damage! Mind the weight of the appliance during transport.

• Press down and push the device using the push handle.

• When transporting in vehicles, secure the appliance according to the guidelines from slipping and

tipping over.

12. STORAGE

CAUTION

Risk of personal injury or damage! Consider the weight of the appliance whenstoring it.

This appliance must only be stored in interior rooms.

13. CARE AND MAINTENANCE

DANGER

Risk of injury! Set the programme selector switch to "OFF" and pull the mains plug of the charger prior to

performing any work on the appliance.

Remove the battery plug from machine.

• Drain and dispose of the dirt water and the residual fresh water.

Maintenance schedule

- After each operation

ATTENTION

Risk of damage. Do not sluice the appliance with water and do not use aggressive detergents.

• Drain off dirt water.

• Rinse the waste water tank with clear water.

• Clean the outside of the appliance with a damp cloth which has been soaked in mild detergent.

• Check the fluff filter, clean if required.

• Clean the vacuum lips and the wiping lips, check for wear and replace if required.

• Check the brush for wear and replace if required (see "Maintenance tasks").

- Monthly

• Check battery poles for oxidation, brush off if necessary. Ensure that the connection cable sits firmly.

• Clean the seals between waste water tank and cover and check for tightness, replace if required.

• Check the acid density of the cells if the batteries are not maintenance-free batteries.

-Yearly

• Have the prescribed inspection carried out by the customer service.

Maintenance works

- Replace or turn vacuum lips

1 Wear indicator

2 Vacuum lip

The vacuum lips must be replaced or reversed

if they are worn down to the wear indicator.

• Remove the vacuum bar.

• Unscrew the bolt..

• Remove the plasticparts.

• Remove the vacuumlips.

• Insert new or reversed vacuum lips.

• Insert the plastic parts.

• Screw in and tighten the bolt..

- Replacing the diskbrushes

• Push down the device holding the push handle so that the cleaning head is raised.

• Press the pedal for changing the brushes downward beyond its resistance.

• Pull the device towards the back so that the disc brush becomes accessible.

• Place a new disc brush on the floor in front of the device.

• Drive the device with the raised cleaning head over the new disc brush and lower the cleaning head.

• The brush locks into the drive.

- Removing the waste water tank

• Drain off dirt water.

• Lift up the waste water tank and put it aside.

- Batteries

Please observe thefollowing warning notes when handling batteries:

DANGER

Risk of explosion. Do not place tools or the like on the battery, i.e. on the terminal poles and cell connec-

tors.

Risk of injury. Ensure that wounds never come into contact with lead. Always clean your hands after

having worked with batteries.

Recommended batteries

The device requires 2 batteries

1) Complete set (24 V/100 Ah) incl. Connecting cable.

Insert batteries and connect

• Drain off dirt water.

• Lift up the waste water tank and put it aside.

• Pull out the battery plug.

1 Spacer

• Insert the battery into the device as shown above.

• Insert the spacer between the battery and the device on the side indicated in the illustration.

CAUTION

When the batteries are installed and removed, the stability of the appliance can be compromised; ensure

a safe stance.

• Connect pole using the enclosed connecting cable.

• Connect the connection cable to the free battery poles (+) and (-).

ATTENTION

If the polarity is reversed (positive and negative terminals), the control electronics are destroyed.

Pay attention to correct poles.

• Place the waste water tank on the appliance.

NOTE: Charge the batteries before commissioning the appliance.

See also "Charging the batteries".

Removing the batteries

• Set the programme selector switch to "OFF".

• Pull out the battery plug.

• Lift up the waste water tank and put it aside.

• Clamp off the minus pole of the battery.

• Clamp off the remaining cables from the battery.

• Remove the support blocks or the foam pieces.

CAUTION

When the batteries are installed and removed, the stability of the appliance can be compromised; ensure

a safe stance.

• Add the detergent to the fresh water reservoir.

NOTE: If the fresh water tank is empty, the cleaning head continues working without liquid

supply.

Setting the water quantity

• Adjust the water quantity using the regulating button according to the dirt on the floor covering.

NOTE: Carry out initial cleaning attempts with low water volume. Increase water volume stepby-

step until the desired cleaning result is achieved.

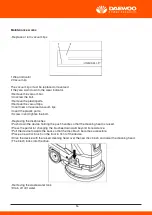

Setting the Vacuum Bar

Oblique position

To improve the vacuuming result on tiled floors the vacuum bar can be turned to an oblique position of up

to 5°.

• Loosen the nuts.

• Turn the vacuum bar.

• Tighten the screws.

Inclination

If the vacuum result is unsatisfactory the inclination of the straight vacuum bar can be modified.

• Adjust the rotary handle to incline the suction bar.

Transport chassis

The transport chassis lifts the cleaning head off the floor.

Transport runs are performed with the cleaning head raised or dirt is vacuumed up.

1 Transport chassis pedal in transport position

9. OPERATION

DANGER

Risk of injury!

In dangerous situations, release the safety switch/drive lever.

Filling in detergents

- Fresh water

• Open the lock of the fresh water reservoir.

• Fill fresh water (maximum 60 °C) until the lower edge of the filling nozzle.

• Close the lock of the fresh water reservoir.

- Detergent

WARNING

Risk of damage. Only use the recommended detergents. With other detergents, the operator bears the

increased risk regarding the operational safety and danger of accident.

Only use detergents that are free fromsolvents, hydrochloric acid and hydrofluoric acid.

Follow the safety instructions for using detergents.

NOTE: Do not use highly foaming detergents.

Recommended detergents:

ATTENTION

Risk of damage!

– Do not connect the charger withthe battery plug on the unit side.

– Only use a charger that is suitablefor the installed battery type:

NOTE: Please read the operating instructions of the charger manufacturer, especially the chapters on

safety instructions!

• Connect the battery plug on the battery side with the charger.

• Plug the mains plug of the charger into a power outlet.

• Execute the charging process according to the information in the operating instructions of the charger.

• Connect the battery plug on the device side with the battery plug on the battery side.

Low maintenance batteries (wet batteries)

WARNING

Danger of causticization!

– Adding water to the battery in its discharged state can cause the acid to leak.

– Use safety glasses while handling battery acid and follow the safety instructions to avoid personal

injury or damage to clothes.

– Should the acid spray on to the skin or clothes, rinse immediately with lots of water.

ATTENTION

Risk of damage!

– Use only distilled or desalinated water (EN 50272-T3) for filling the battery.

– Do not add any substances (so-called performance improving agents), else warranty claims will not be

entertained.

– Replace batteries with the same battery type only.

Installing the Vacuum Bar

• Insert the vacuum bar into the vacuum bar suspension in such a manner that the profiled sheet is

positioned above the suspension.

• Tighten the nuts.

• Insert the suction hose.

Install batteries

Install the batteries (see "Care and Maintenance/Install and connect batteries").

Using batteries made by other manufacturers

We recommend using our batteries as described in chapter "Care and Maintenance/ Recommended

batteries".

Charging battery

NOTE: The device is equipped with a safety mechanism to prevent total discharge, i.e. when the permis-

sible minimum capacity is reached, the brush motor and the turbine are switched off.

• Drive the machine directly to the charging station; avoid any steep gradients in the process.

DANGER

Danger of injury due to electric shock. Observe the mains voltage and fuse protection on the type plate of

the device.

Charging process

Average charging time is approx. 10 -15 hours.

The appliance must not be used during the charging process.

DANGER

Danger of explosion

Prior to charging low-maintenance batteries

Remove waste water tank (see Chapter "Maintenance and care/Maintenance tasks/Removing the waste

water tank"). This prevents the accumulation of hazardous gases underneath the tank during the char-

ging process.

ATTENTION

Risk of damage. Do not clean the device with water while the tank is removed.

1 Battery plug, appliance side

2 Battery plug, battery side

• Detach the battery plug on the unit side.

6. OPERATOR CONSOLE

7. SYMBOLS ON THE MACHINE

** option

8. BEFORE STARTUP

Unloading

• Unscrew the screws from the middle board of the pallet.

• Push down the device holding the push handle and pull out the middle board.

• Remove the chocks in front of and next to the wheels.

• Push down the device holding the push handle and push it forwards up to the edge of the pallet.

• Lift the device off the pallet and set it on the floor.

5. OPERATING AND FUNCTIONAL ELEMENTS

Safety switch

If the safety switch is released, the brush drive shuts off.

Danger or hazard levels

DANGER

For an immediate danger which can lead to severe injuries or death.

WARNING

For a possibly dangerous situation which could lead to severe injuries or death.

CAUTION

Pointer to a possibly dangerous situation, which can lead to minor injuries.

ATTENTION

Pointer to a possibly dangerous situation, which can lead to property damage.

3. FUNCTION

The scrubbing vacuum cleaner is used for the wet cleaning of level floors.

– The device can be easily adjusted to the respective cleaning task by adjusting the water volume and

the detergent volume.

The detergent dosing unit can be adjusted via the addition in the tank.

– The device is equipped with a fresh water and a waste water tank (50 litres each). These allow an

effective cleaning with a long usage life.

– A working distance of 500 mm will improve the efficiency when you are using the appliance for a long

period.

– Propulsion is accomplished bymanually pushing the appliance and is supported by the rotation of the

brushes. The brush drive is powered by two batteries.

– The extendible transport chassisensures easy transport runs.

– Batteries can be selected depending on the configuration (refer to Chapter "recommended batteries")

NOTE:

The appliance can be equipped with various accessories depending on the cleaning task.

Please request our catalogue or visit us on the Internet.

4. PROPER USE

Use this appliance only as directed in these operating instructions.

– The appliance may only be used for the cleaning of hard surfaces that are not sensitive to moisture and

polishing operations.

– The appliance is not suited for the cleaning of frozen grounds (e.g. in cold stores).

– The appliance may only beequipped with original accessories and spare parts.

– The appliance is not suited for the use in potentially explosiveenvironments.

– The machine should not be used to suck in inflammable gases, undiluted acids or solvents.

This includes petrol, thinning agents or hot oil that can form an explosive mixture when it comes in

contact with sucked air. Do not use acetone, undiluted acids and solvents as they are aggressive

towards the materials from which the appliance is made.

– The machine has been approved for use on surfaces with max. gradients as listed under "Technical

specifications".

– This appliance is suited for the commercial use, e.g. in hotels, schools, hospitals, factories, shops,

offices, and rental companies.

– The appliance was designed for the cleaning of floors inside or of covered surfaces.

2. SAFETY INSTRUCTIONS

Before using the appliance for the first time, read and observe these operating instruc tions and the

accompanying brochure: Safety information for brush cleaning units and spray-extraction units,

No. 5.956-251.0.

The device may only be operated when the cover and all lids are closed. The appliance must only be

operated on surfaces that do not exceed the max. permitted incline (see "Technical Specifications").

WARNING

Do not use the appliance on inclines.

Safety devices

Safety devices serve to protect the user and must not be rendered in operational or their functions bypas-

sed.

Summary of Contents for DAFL55B

Page 22: ...22 Transport angle wheel structure diagram...

Page 23: ...EN 23 Sewage tank structure diagram...

Page 24: ...24 Drawing of suction rack structure Structure diagram of clean water tank...

Page 25: ...EN 25...

Page 26: ...26 Brush structure diagram Suction structure diagram...

Page 27: ...EN 27...