3

1. POINTS FOR ATTENTION

1. Before use, fix all parts well according to assembly drawing and wrench firm without leakage;

2. Fill in filtered water and note never to fill in dirty water to avoid blockage;

3. During boosting, never use too high pressure yo avoid damaging metallic parts. The service

pressure should be between 0.2-0.3 Mpa;

4. If there will be a long term out of service, please rinse it with clarified water or soap water and

then put it in dry and airy place;

5. Often add lubricant into leather cup;

6. In case of the blockage of shower head, never use a sharp tool to deadge it to avoid damage;

7. Often clean the filter apparatus.

2. FITTINGS LIST

The product has the following advantages and characteristics:

(A) Unique structure of air compartment, novel design, putting forth one´s fewer strength, rapid

pressure-increasing and high efficiency;

(B) Big volume of air compartment (over 0.85 liter) and long spraying time;

(C) Rapid pressure boosting (the cylinder is three times bigger than ordinary one;

(D) Strong anticorrosion ability since it´s internal structure adopts quality plastics;

(E) Easy and covenient to store and carry, spraying pipe and rocker have the function of clipping

and fixing;

(G) Easy to maintain and repair, spraying parts are in common use with those of ordinaty models;

(H) Tasteful and luxurious appearance. It´s above advantages and characteristics change original

outdated styles and make sprayer become much reasonable and applicable. The product accordin-

gly conforms to the requirements of international advenced equipment for plant protection. As a

substitute and upgraded product of Daewoo Brand Model 16, it´s widely used not only in the

prevention and control of plant diseases and elimination of pests of crop, cotton, vegetables and

fruit trees but also in the pest-killing and environmental disingection of room, public sites and poul-

try coop.

The comprany has a normal management and a complete set of testing means. It also strictly

abides by contract and conducts “Three responsibilities” policy. We sincerely welcome the broad

users to choose out products and give us the valuable opinions.

3. PARTS LIST

• Parts 5, 6. Parts 33, 34 and part 38 are all filtering apparatus, which are allowed to use in two

places.

• If necessary, a small air compartment can be added at the left side of barrel as per user´s require-

ment, which will futher enlarge the volume of aire compartment to fulfil

the purpose of extening spraying time and increasing pressure. Thus, “Q” will be added after the

model No.

• If partial parts need to be changed, excuse us for not advising.

4. BREAKDOWN ANALYSIS

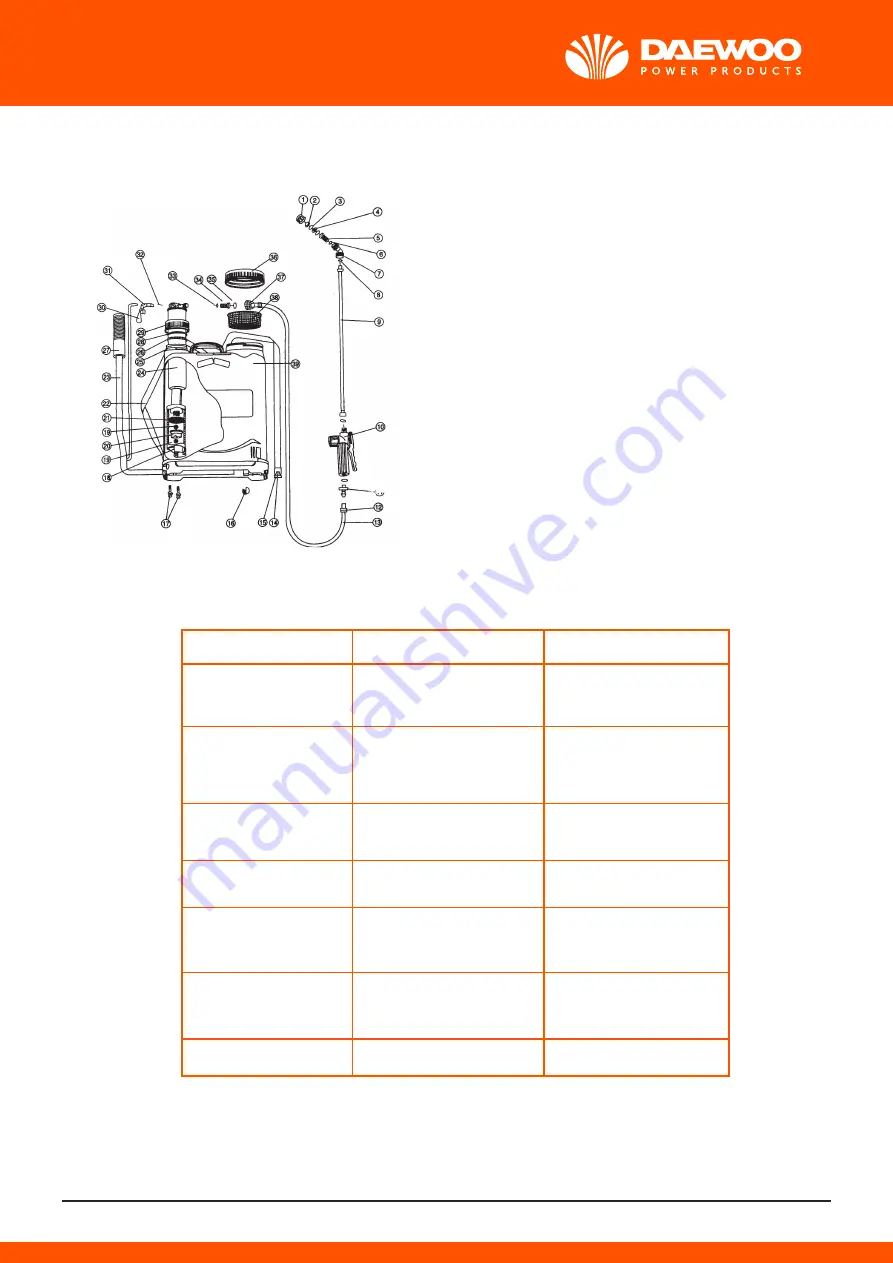

1. Shower head cap - x1

2. Round spray slice - x1

3. Washer 12x6 - x2

4. Round spray core - x1

5. Small strainer - x2

6. “O” Ring 14x13 - x1

7. Spray cup - x1

8. Washer 14x18 - x3

9. Jet tube - x1

10. Switch component - x1

11. Rubber tube screw - x1

12. Rubber tube bail - x2

13. Rubber tube - x1

14. Back belt hook - x2

15. Back belt striking palte - x2

16. Rocker locatot - x1

17. M8 Screw - x2

18. Cylinder - x1

19. Glass ball - x2

20. Vlave cap - x1

21. Leather cup - x1

22. Back belt - x2

23. Rocker - x1

24. Air compartment - x1

25. Locotor sleeve - x1

26. Weight cap - x1

27. Handle - x1

28. Linoleum - x1

29. Linoleum weight cap - x1

30. Rocker hanging ring - x1

31. Jet tube clip - x1

32. Open-end pin 2.5x20 - x2

33. “O” Ring 14x13 - x1

34. Small strainer - x1

35. Washer 12x16 - x1

36. Filler cap - x1

37. Rubber tube cap - x1

38. Strainer plate - x1

39. Barrel - x1

Leakage

1. No install sealing plate

2. Sealing plate is damaged

3. Not be wrenched firm

Replace sealing plate or

wrench firm

Water drip from cylinder

1. Leather cup was worn out

(too big gap)

Replace

Overweight rocker or send

forth piercing sound

during rocking

1. Dry friction between leather cup

and cylinder

2. Leather cup excessively expands

1. Add lubricant

2. Replace leather cup

3. Rinse leather cup and let it dry,

add for using again

Can´t draw water out or

pressure not high enough

1. Glass ball is not opened

2. Glass ball falls

3. Seriously blocked

Disassemble and rinse, then install

according to instructions and

assembly drawing.

Return to upward position

in case rocking stops

1. Glass ball in air compartment fall

2. There is foreign matter on glass

ball in air compartment

3. Valve cap is broken and deformed

1. Clear foreign matter on glass ball

2. Use filtered water

3. Replace valve cap

Bad spraying

1. Foreign matter blocks spray cup

2. Spray slice and spray core

are broken

1. Separate and eliminate

foreign matter

2. Replace spray slice and

spray core

Metallic parts deform

Excessive pressure, overexert

1. Replace metallic parts,

pay attention to proper pressure

Breakdown

Cause

analysis

Fix

method