Summary of Contents for DAPD15REG-EB

Page 1: ...DAPD REG EB www daewoopowerproducts com Gas generator USER S MANUAL...

Page 39: ...39 EN Three Phase ATS Wiring Diagram...

Page 40: ...40 Controller Wiring Diagram...

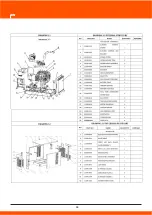

Page 61: ...61 8 SPARE PARTS LIST...

Page 62: ...62 EN...

Page 63: ...63...

Page 64: ...64 EN...

Page 65: ...65...

Page 66: ...66 EN...

Page 68: ...PR...

Page 69: ...NG LPG ISO...

Page 70: ...PR NG LPG ATS BNL SE BNL SE I...

Page 71: ...35...

Page 72: ...AC...

Page 73: ...35 ON OFF OFF CC SD SE SF SAE F C SAE W or W F to C SAE W or W F C SAE W or W...

Page 74: ...qts NG LPG LP LP...

Page 75: ...35 A LP ATS...

Page 76: ...ATS...

Page 77: ...35...

Page 78: ...OFF x...

Page 79: ...PR x NG LPG x API SE SP SG...

Page 80: ...x x x x x A B B A B...

Page 81: ...PR x...

Page 82: ...FULL...

Page 83: ...PR kgf lbs LCD...

Page 84: ...CFR I...

Page 85: ...PR AUTO OFF MANUAL ABC...

Page 86: ...NG LPG ETL ATS ETL AC NEC NEC AFCI...

Page 87: ...PR...

Page 88: ......

Page 89: ...PR F C SAE W W F C SAE W W F C SAE W W qts...

Page 90: ...LPG NG NG LPG LPG LP LPG NG LPG NG...

Page 91: ...35 LP AGA LP UL Listed AGA...

Page 92: ......

Page 93: ...35...

Page 94: ......

Page 95: ...35 GND GND AC ATS AC AWG...

Page 96: ...Controller O AUTO LED Close Gen...

Page 97: ...35 WTH STOP by cool LCD XX s LCD LCD Safety On LCD...

Page 98: ...Fail to stop LCD AWG AWG AWG AWG AWG AWG...

Page 99: ...35 DC AC AC DC...

Page 100: ...ATS...

Page 101: ...35 Three Phase ATS Wiring Diagram...

Page 102: ......

Page 105: ...35 ATS UL EZ...

Page 106: ...ATS EZ AC ATS...

Page 107: ...35 ATS OFF AUTO ON ON...

Page 108: ...x x x x ATS GND GND AC ATS AC AWG...

Page 109: ...35 NFPA E...

Page 110: ...MANUAL ATS BNL SE OFF OFF ON ATS AUTO ON...

Page 111: ...35 A B N M N M...

Page 112: ...B B...

Page 113: ...35 FULL...

Page 114: ......

Page 118: ......

Page 119: ...EN AC AVR 35...

Page 121: ...EN HSC IP ft M dB A PET NG m hr LPG kg hr NG kPa LPG kPa mm mm kg kg...

Page 122: ......

Page 123: ......

Page 124: ...35...

Page 125: ......

Page 126: ...35...

Page 127: ......

Page 128: ...ration Korea...