www.daewoopower.bg

21

19

1. SPECIFICATIONS

2. WARNING LABELS ON THE MACHINE

3. SYMBOLS ON THE MACHINE

4. SAFETY PRECAUTIONS

WARNING - READ BEFORE OPERATION

A chainsaw is a high-speed, fast cutting power tool and as a result special safety precautions must be

taken to reduce the risk of personal injury.

SAFETY PRECAUTION

Please read this manual carefully prior to operating the chain saw. It contains important safety,

maintenance and operating instructions. Read these instructions thoroughly even if you are already

familiar with chainsaw use. This product should not be used for any other purpose than described.

National regulations can restrict the use of the product.

OPERATOR SAFETY

- Do not operate the chainsaw when you are tired, ill or under the influence of medication, alcohol or

drugs. Do not operate the saw if you are fatigued.

- Always wear a safety face shield or goggles.

- Always wear safety protective equipment such as Angus fitting clothing (jacket, trousers) gloves,

boots with steel toecaps and non-slip soles. Chainsaw chaps add a layer of safety. Do not wear short,

loose clothing such as scarves, jewelry, sandals, or go barefoot. Loose clothing may become tangled

in branches or the chainsaw.

- Wear hearing protection. Hearing damage is cumulative.

- Wear non-slip, heavy-duty work gloves to improve your grip on the chainsaw handles. Keep chainsaw

handles free of oil and fuel.

- Never let a minor or inexperienced person operate the chainsaw. Bystanders, especially children and

animals should be kept out of the area where the chainsaw is in use.

- Never start or run the chainsaw in an enclosed area. The exhaust fumes contain Carbon.

- Keep hands away from the chain cutter. Do not grab or hold the chainsaw by the chain.

- When the chainsaw is turned off, make sure the chain has stopped before placing the unit down.

- Take a break if you have used the chainsaw for a prolonged period of time. Long-term exposure to

vibration can result in white-finger disease, a loss of sensation in the hands and the inability to feel and

regulate temperature.

- Obey all the local regulations of the cutting area or municipality.

UNIT/TOOL SAFETY

- Inspect the chainsaw carefully before each use. Replace any damaged parts before use. Check for

fuel leaks and tighten any loose fasteners.

- Never modify the chainsaw and use only approved replacement parts for repair work.

- Check chain tension before each use and in between fueling breaks. The chain will lengthen with use

especially during the running-in period. A slack chain is dangerous.

- Never let the chain strike anything. If the chain makes contact, stop the chainsaw and inspect for

damage. Replace any damaged parts before use.

- Make sure the automatic oiler is working. Keep the oil tank filled with clean chain bar oil. Never let the

chain run dry on the bar.

- All chainsaw service, other than the items listed in this manual, should be performed by qualified

chainsaw service personnel.

CHAINSAW USE SAFETY

- Never transport the chainsaw with the chain moving, even for a few steps. Engage the chain brake.

For longer distances, shut off the engine, cover the chain with the chain guard (scabbard) and carry the

saw in a horizontal position, keeping the hot muffler away from you and the chain facing backwards.

- Do not use the chainsaw to cut any material other than wood or wood objects.

- When cutting wood sprayed with insecticide, use a NIOSH filter mask for respiratory protection. -Stop

the chainsaw engine immediately should children, animals, bystanders or helpers enter the cutting

hazard zone.

- Hold the chainsaw firmly with both hands with the thumb firmly locked over the front handle. The

chainsaw must be held with the right hand on the rear handle and the left hand on the front handle.

- Never cut using one hand.

- While cutting, maintain a firm and balanced footing. Keep your body balanced and never over-reach.

- Keep the muffler and saw chain away from all parts of the body while the engine is running. Keep the

bar/chain below waist level.

- Stand to the side of the saw while cutting, never directly behind it.

- Preplan a safe exit from a falling tree before starting the sawing. -Be alert against a kickback. Never

cut with the nose of the bar.

- Only use cutting attachments as listed in the technical data within these instructions. The use of other

attachments leads to hazards resulting in personal injuries and damage to property.

FUELING SAFETY

- Maintain the chainsaw according to the recommended schedule listed in the manual.

- Disconnect spark plug before performing maintenance except for carburetor adjustments.

- Keep bystanders away from the saw while adjusting carburetor.

- Use only replacement parts authorized for the chainsaw while making repairs or maintaining the saw.

- Inspect the product before each use, after dropping the products or exposing to other impacts to

identify significant defects.

- Secure the product during transport to prevent loss of fuel, damage and injury.

- Clean and maintain the product as described in these instructions before storage. Always use guards

on saws when storing.

- Attach the transportation cover for the saw during transport and storage.

TRANSPORT AND STORAGE SAFETY

- Always carry the saw with the engine stopped, muffler away from the body and chain facing

backwards.

- Allow the engine to cool, empty the fuel tank, cover the chain with the scabbard, and secure the saw

before storing or transporting in a vehicle.

- Empty the fuel tank before storing the saw. We recommend emptying the fuel tank after each use.

- If fuel is left in tank, store in a position so as to prevent leakage.

- Always to use guide-bar cover during transport and storage.

- Clean the saw prior to storage and maintenance. Store the unit with chain covered and out of reach

of children.

5. FOR SAFE OPERATION

1. Never operate a chain saw when you are fatigued, ill, or upset, or under the influence of medication

that may make you drowsy, or if you are under the influence of alcohol or drugs.

2. Use safety footwear, snug fitting clothing and eye, hearing and head protection devices. Use the

vibration-proof glove.

3. Keep the saw chain sharp and the saw, including the AV system, well maintained.

A dull chain will increase cutting time, and pressing a dull chain through wood will increase the

vibrations transmitted to your hands. A saw with loose components or with damaged or worn AV

buffers will also tend to have higher vibration levels.

4. Always use caution when handling fuel. Wipe up all spills and then move the chain saw at least 3 m

from the fueling point before starting the engine.

5. Eliminate all sources of sparks or flame (i.e. smoking, open flames, or work that can cause sparks) in

the areas where fuel is mixed, poured, or stored.

6. Do not smoke while handling fuel or while operating the chain saw.

7. Do not allow other persons to be near the chain saw when starting or cutting. Keep bystanders and

animals out of the work area. Children, pets and bystanders should be a minimum of 10 m away when

you start or operate the chain saw.

8. Never start cutting until you have a clear work area, secure footing, and a planned retreat path from

the falling tree.

9. Always hold the chain saw firmly with both hands when the engine is running. Use a firm grip with

thumb and fingers encircling the chain saw handles.

10. Keep all parts of your body away from the saw chain when the engine is running.

11. Before you start the engine, make sure the saw chain is not contacting anything.

12. Always carry the chain saw with the engine stopped the guide bar and saw chain to the rear, and

the muffler away from your body.

13. Always inspect the chain saw before each use for worn, loose, or dam-aged parts.

Never operate a chain saw that is damaged, improperly adjusted, or is not completely and securely

assembled. Be sure that the saw chain stops moving when the throttle control trigger is released.

14. All chain saw service, other than the items listed in the Owner’s Manual, should be performed by

competent chain saw service personnel.

15. Always shut off the engine before setting it down.

16. Use extreme caution when cutting small size brush and saplings because slender material may

catch the saw chain and be whipped toward you or pull you off balance.

17. When cutting a limb that is under tension, be alert for spring- back so that you will not be struck

when the tension in the wood fibers is released.

18. Never cut in high wind, bad weather, when visibility is poor or in very high or low temperatures.

Always check the tree for dead branches which could fall during the felling operation.

19. Keep the handles dry, clean and free of oil or fuel mixture.

20. Operate the chain saw only in well ventilated areas. Never start or run the engine inside a closed

room or building and potentially explosive atmosphere. Exhaust fumes contain dangerous carbon

monoxide.

21. Do not operate the chain saw in a tree unless specially trained to do so.

22. Guard against kickback. Kickback is the upward motion of the guide bar which occurs when the

saw chain at the nose of the guide bar contacts an object. Kickback can lead to dangerous loss of

control of the chain saw.

23. When transporting your chain saw, make sure the appropriate guide bar scabbard

is in place.

24. Never touch the cover, guide bar, saw chain or nut with bare hands while the engine is in operation

or immediately after shutting down the engine. Doing so could result in serious burns because of high

temperature.

KICKBACK SAFETY RECAUTIONS FOR CHAIN SAW USERS

Kickback may occur when the nose or tip of the guide bar touches an object, or when

the wood closes in and pinches the saw chain in the cut. Tip contact in some cases

may cause a lightning fast reverse reaction, kicking the guide bar up and back towards

the operator. Pinching the saw chain along the top of the guide bar may push the

guide bar rapidly back towards the operator. Either of these reactions may cause you

to lose control of the saw, which could result in serious personal injury.

Do not rely exclusively on the safety devices built into your saw. As a chain saw user you should take

several steps to keep cutting jobs free from accident or injury.

(1) With a basic understanding of kick-back you can reduce or eliminate the element of surprise.

Sudden surprise contributes to accidents.

(2) Keep a good grip on the saw with both hands, the right hand on the rear handle, and the left hand

on the front handle, when the engine is running. Use a firm grip with thumbs and fingers encircling the

chain saw handles. A firm grip will help you reduce kickback and maintain control of the saw.

(3) Make certain that the area in which you are cutting is free from obstructions. Do not let the nose of

the guide bar contact a log, branch, or any other obstruction which could be hit while you are

operating the saw.

(4) Cut at high engine speeds.

(5) Do not overreach or cut above shoulder height.

(6) Follow the manufacturer’s sharpening and maintenance instructions for the saw chain.

(7) Only use replacement bars and chains specified by the manufacturer or the equivalent.

WORSE EFFECTS OF VIBRATION

If you continue to use high-vibration tools these symptoms will probably get worse, for example:

the numbness in your hands could become permanent and you won’t be able to feel things at all;

you will have difficulty picking up small objects such as screws or nails;

the vibration white finger could happen more frequently and affect more of your fingers.

FOR PROTECTING YOUR BODY FROM VIBRATION

Please observe the following matter, in order to protect the health of your body.

1. Always use the right tool for each job (to do the job more quickly and expose you to less hand-arm

vibration).

2. Check tools before using them to make sure they have been properly maintained and repaired to

avoid

increased vibration caused by faults or general wear.

3. Make sure cutting tools are kept sharp so that they remain efficient.

4. Reduce the amount of time you use a tool in one go, by doing other jobs in between.

5. Avoid gripping or forcing a tool or work piece more than you have to.

6. Store tools so that they do not have very cold handles when next used.

6. INSTALLING GUIDE BAR AND SAW CHAIN

A standard saw unit package contains the items as illustrated.

Open the box and install the guide bar and the saw

chain on the power unit as follows:

WARNING The saw chain has very sharp edges. Use thick

protective gloves for safety.

1. Pull the guard towards the front handle to check that the chain brake is not engaged.

2. Loosen the nuts and remove the chain cover.

3. Install the attached spike to the power unit.

4. Gear the chain to the sprocket and, while fitting the saw chain around the guide bar, mount the guide

bar to the power unit. Adjust the position of chain tensioner nut on the chain cover to the lower hole of

guide bar.

(1)

Hole

(2)

Tensioner

nut

(3)

Chain

cover

NOTE

Pay attention to the correct direction of the saw chain.

Moving direction

5. Fit the chain cover to the power unit and fasten the nuts to finger tightness.

6. While holding up the tip of the bar, adjust the chain tension by turning the tensioner screw until the

tie straps just touch the bottom side of the bar rail.

(1)

Tensioner

screw

(2)

Loosen

(3)

Tighten

7. Tighten the nuts securely with the bar tip held up (12 ~ 15 N•m). Then check the chain for smooth

rotation and proper tension while moving it by hand. If necessary, readjust with the chain cover loose.

8. Tighten the tensioner screw.

NOTE

A new chain will expand its length in the beginning of use. Check and readjust the tension frequently as

a loose chain can easily derail or cause rapid wear of itself and the guide bar.

7. FUEL AND CHAIN OIL

FUEL

WARNING

• Gasoline is very flammable. Avoid smoking or bringing any flame or sparks near fuel.

• Wipe up all spills before starting the engine.

• Make sure to stop the

engine and allow it cool before refueling the unit.

• Keep open flames away from the area where fuel is handled or stored.

IMPORTANT

• Never use oil for 4 cycle engine use or water cooled 2-cycle engine.

• Never use "FUEL WITH NO OIL (RAW GASOLINE)".

• Never use fuel laced with water.

• Mixed fuels which have been left unused for a period of one month or more may clog the carburetor

or result in the engine failing to operate properly. Put remained fuel into an air-tight container and keep

it in the dark and cool room.

• Please ask for “mixed gasoline for air-cooled 2-cycle engines” at your nearest gas station, or use fuel

made by putting unleaded gasoline for automobiles and air-cooled 2-cycle engine oil into a mixing

container in accordance with the following ratios and then shaking to mix well.

HOW TO MIX FUEL

1. Measure out the quantities of gasoline and oil to be mixed.

2. Put some of the gasoline into a clean, approved fuel container.

3. Pour in all of the oil and agitate well.

4. Pour in the rest of gasoline and agitate again for at least one minute. As some oils may be difficult to

agitate depending on oil ingredients, sufficient agitation is necessary for the engine to last long. Be

careful that, if the agitation is insufficient, there is an increased danger of early piston seizing due to

abnormally lean mixture.

5. Put a clear indication on the outside of the container to avoid mixing up with gasoline or other

containers.

6. Indicate the contents on outside of container for easy identification.

RECOMMENDED MIXING RATIO:

GASOLINE 40 : OIL 1

FUELING THE UNIT

1. Untwist and remove the fuel cap. Rest the cap on a dustless place.

2. Put fuel into the fuel tank to 80% of the full capacity.

3 Fasten the fuel cap securely and wipe up any fuel spillage around the unit.

WARNING

1. Select flat and bare ground for fueling.

2. Move at least 10 feet (3 meters) away from the fueling point before starting the engine.

3. Stop the engine before refueling the unit. At that time, be sure to sufficiently agitate the mixed

gasoline in the container.

4. In the case of storing the product for a long period of time, clean the fuel tank after rendering it

empty. Next, activate the engine and empty the carburetor of the composite fuel.

CHAIN OIL

Use motor oil SAE #10W-30 all year round or SAE #30

~ #40 in summer and SAE #20 in winter.

NOTE

Do not use wasted or regenerated oil that can cause damage to the oil pump.

8. OPERATING THE ENGINE

WARNING

It is very dangerous to run a chainsaw that mounts broken parts or lacks any parts. Before starting

engine, make sure that all the parts including bar and chain are installed properly.

STARTING THE ENGINE

1. Fill fuel and chain oil tanks respectively, and tighten the caps securely.

(1) Chain oil

(2) Fuel

2. Set the switch to “I” position.

3. Pull out the choke knob to the closed position.

Choke knob

NOTE

When restarting immediately after stopping the engine, leave the choke knob at the open position.

4. While holding the saw unit securely on the ground, pull the starter rope vigorously.

WARNING

Do not start the engine while the chain saw hangs in one hand. The saw chain may touch your body.

This in very dangerous.

5. When engine has ignited first, pull the throttle lever to return the choke knob to the open position

and then pull the starter again to start the engine.

6. Allow the engine to warm up with the throttle lever pulled slightly.

WARNING

Keep clear of the saw chain as it will start rotating upon starting of engine.

CHECKING THE OIL SUPPLY

WARNING

Make sure to set up the bar and the chain when checking the oil supply. If not, the rotating parts may

be exposed. It is very dangerous.

After starting the engine, run the chain at medium speed and see if chain oil is scattered off as shown

in the figure.

Chain oil

The chain oil flow can be changed by inserting a screw-driver in the hole on bottom of the clutch side.

Adjust according to your work conditions.

Chain oil flow adjusting

NOTE

The oil tank should become nearly empty by the time fuel is used up. Be sure to refill the oil tank every

time when refueling the saw.

ADJUSTING THE CARBURETOR

(1)

L

needle

(2)

H

needle

(3) Idle adjusting screw

The carburetor on your unit has been factory

adjusted, but may require fine tuning due to a change in operating conditions. Before adjusting the

carburetor, make sure that the provided air/fuel filters are clean and fresh and the fuel properly

mixed.

When adjusting, take the following steps:

NOTE

Be sure to adjust the carburetor with the bar chain attached.

1. H and L needles are restricted within the number of turn as shown below.

H needle: -1/4 -1/4

L needle: -1/4 -1/4

2. Start the engine and allow it to warm up in low speed for a few minutes.

3. Turn the idle adjusting screw (T) counterclockwise so that the saw chain does not turn. If the idling

speed is too slow, turn the screw clockwise.

4. Make a test cut and adjust the H needle for best cutting power, not for maximum speed.

CHAIN BRAKE

This machine is equipped with an automatic brake to stop saw chain rotation upon occurrence of

kickback during saw cutting. The brake is automatically operated by inertial force, which acts on the

weight fitted inside the front guard. This brake can also be operated manually with the front guard

turned down to the guide bar. To release the brake, pull up the front guard toward the front handle till a

“click” sound is heard.

WARNING

Be sure to confirm brake operation during daily inspection.

How to confirm:

1) Turn off the engine.

2) Holding the chain saw horizontally, release your hand from the front handle, hit the tip of the guide

bar to a stump or a piece of wood, and confirm brake operation. Operating level varies by bar size.

In case the brake is not effective, ask our dealer for inspection and repairs. If the engine keeps rotating

at high speed with the brake engaged, the clutch will overheat causing trouble. When the brake

engages during operation, immediately release the throttle lever to stop the engine.

STOPPING THE ENGINE

1 Release the throttle lever to allow the engine to idle for a few minutes.

2 Set the switch to the “O” (STOP) position.

Before proceeding to your job, read the section “For Safe Operation”. It is recommended to first

practice sawing easy logs. This also helps you get accustomed to your unit.

Always follow the safety regulations. The chain saw must only be used for cutting wood. It is forbidden

to cut other types of material.

Vibrations and kickback vary with different materials and the requirements of the safety regulations

would not be respected.

Do not use the chain saw as a lever for lifting, moving or splitting objects. Do not lock it over

fixed stands. It is forbidden to hitch tools or applications to the PTO other than those specified by the

manufacturer.

It is not necessary to force the saw into the cut.

Apply only light pressure while running the engine at full throttle.

When the saw chain is caught in the cut, do not attempt to pull it out by force, but use a wedge or a

lever to open the way.

GUARD AGAINST KICKBACK

This saw is equipped with a chain brake that will stop the chain in the event of kickback if operating

properly. You must check the chain brake operation before each usage by running the saw at full the

throttle for I 2 seconds and pushing the front hand guard forward. The chain should stop immediately

with the engine at full speed. If the chain is slow to stop or does not stop, replace the brake band and

clutch drum before use.

It is extremely important that the chain brake be checked for proper operation before each use and

that the chain be sharp in order to maintain the kickback safety level of this saw. Removal of the safety

devices, inadequate maintenance, or incorrect replacement of the bar or chain may increase the risk to

serious personal injury due to kickback.

FELLING A TREE

Felling direction

Notch

cut

Felling

out

1. Decide the felling direction considering the wind, lean of the tree, location of heavy branches, ease

of completing the task after felling and other factors.

2. While clearing the area around the tree, arrange a good foothold and retreat path.

3. Make a notch cut one-third of the way into the tree on the felling side.

4. Make a felling cut from the opposite side of the notch and at a level slightly higher than the bottom

of the notch.

WARNING

When you fell a tree, be sure to warn neighboring workers of the danger.

9. SAWING

Bucking and Limbing

WARNING

Always ensure your foothold. Do not stand on the log.

Be alert to the rolling over of a cut log.

Especially when working on a slope, stand on the uphill side of the log.

Follow the instructions in “For Safe Operation” to avoid kickback of the saw.

Before starting work, check the direction of bending force inside the log to be cut. Always finish cutting

from the opposite side of the bending direction to prevent the guide bar from being caught in the cut.

A log lying off the ground

Saw down halfway, then roll the log over and cut from the opposite side.

A log hanging off the ground

In area A, saw up from the bottom one-third and finish by sawing down from the top .In area B, saw

down from the top one-third and finish by sawing up from the bottom.

Cutting the limbs of Fallen Tree

First check to which side the limb is bent. Then make the initial cut from the bent side and finish by

sawing from the opposite side.

WARNING

Be alert to the springing back of a cut limb.

Pruning of Standing Tree

Cut up from the bottom, finish down from the top.

WARNING

Do not use an unstable foothold or ladder.

Do not overreach.

Do not cut above shoulder height.

Always use both your hands to hold the saw.

10. MAINTENANCE

Before cleaning, the inspecting or repairing the unit, make sure that engine has stopped and is cool.

Disconnect the spark plug to prevent accidental starting.

MAINTENANCE AFTER EACH USE

1. Air filter

Dust on the cleaner surface can be removed by tapping a corner of the cleaner against a hard surface.

To clean dirt in the meshes, split the cleaner into halves and brush in gasoline. When using compres-

sed air, blow from the inside.

To assemble the cleaner halves, press the rim until it clicks.

When installing the main filter, make sure that the grooves on the filter edge are correctly fit with the

projections on the cylinder cover.

2. Oiling port

Dismount the guide bar and check the oiling port for clogging.

Oiling port

3. Guide bar

When the guide bar is dismounted, remove sawdust in the bar groove and the oiling port. Grease the

nose sprocket from the feeding port on the tip of the bar.

4. Others

Check for fuel leakage and loose fastenings and damage to major parts, especially handle joints and

guide bar mounting. If any defects are found, make sure to have them repaired before operating the

saw again.

PERIODICAL SERVICE POINTS

1. Cylinder fins

Dust clogging between the cylinder fins will cause overheating of the engine. Periodically check and

clean the cylinder fins after removing the air cleaner and the cylinder cover. When installing the cylin-

der cover, make sure that switch wires and grommets are positioned correctly in place.

4. Others

Check for fuel leakage and loose fastenings and damage to major parts, especially handle joints and

guide bar mounting. If any defects are found, make sure to have them repaired before operating the

saw again.

PERIODICAL SERVICE POINTS

1. Cylinder fins

Dust clogging between the cylinder fins will cause overheating of the engine. Periodically check and

clean the cylinder fins after removing the air cleaner and the cylinder cover. When installing the cylin-

der cover, make sure that switch wires and grommets are positioned correctly in place.

Be sure to block the air intake hole.

2. Fuel filter

(a) Using a wire hook, take out the filter from the filler port.

(b) Disassemble the filter and wash with gasoline, or replace with a new one if needed.

After removing the filter, use a pinch to hold the end of the suction pipe.

When assembling the filter, take care not to allow filter fibers or dust inside the suction pipe.

3. Oil tank

With a wire hook, take out the oil filter through the filler port and clean in gasoline. When putting the

filter back into the tank, make sure that it comes to the front right corner. Also clean off dirt in the tank.

4. Spark plug

0.6 ~ 0.7 mm

5. Sprocket

Check for cracks and for excessive wear interfering with the chain drive. If the wear is considerable,

replace it with new one. Never fit a new chain on a worn sprocket, or a worn chain on a new sprocket.

6. Front and Rear dampers

Replace if adhered part is peeled or crack is observed on the rubber part.

Saw Chain

It is very important for smooth and safe operation to always keep the cutters sharp.

The cutters need to be sharpened when:

1.

Sawdust becomes powder-like.

2.

You need extra force to saw in.

3.

The cut path does not go straight.

4.

Vibration increases.

5.

Fuel consumption increases.

Cutter setting standards:

Be sure to wear safety gloves.

Before filing:

•

Make sure the saw chain is held securely.

•

Make sure the engine is stopped.

•

Use a round file of proper size for the chain.

Place the file on the cutter and push straight forward. Keep the file position as illustrated.

After each cutter has been filed, check the depth gauge and file it to the proper level as illustrated.

Appropriate gauge checker

Make the shoulder round

Depth gauge standard 0.025”

(0.64 mm)

Be sure to round off the front edge to reduce the chance of kickback or tie-strap breakage.

Make sure every cutter has the same length and edge angles as illustrated.

Cutter length

Filing angle

Side plate angle

Top plate cutting angle

Guide Bar

•

Reverse the bar occasionally to prevent partial wear.

•

The bar rail should always be square. Check for wear of the bar rail. Apply a ruler to the bar

and the outside of a cutter. If a gap is observed between them, the rail is normal. Otherwise, the bar

rail is worn. Such a bar needs to be corrected or replaced.

11. TROUBLESHOOTING GUIDE

Make sure the icing prevention system is not working.

Ruler

Gap

No gap

Case 2.Lack of power

Rough idling

/Poor acceleration/

Case 3. Oil does not come out

If the unit seems to need further service, please

consult with an authorized service shop in your area.

Check fuel for water or

substandard mixture.

Check fuel for water or

substandard mixture.

Check for engine

flooding.

Check spark ignition.

Replace with proper

Remove and dry the

spark plug.

Then pull the starter

again with no choke.

Check fuel for water

substandard

mixture.

Check air filter and fuel

filter for clogging.

Check carburetor for

inadequate adjustment.

Replace with proper

fuel.

Clean.

Readjust speed

needles.

Check oil for

substandard

quality.

Check oil passage

and ports for clogging.

Replace.

Clean.

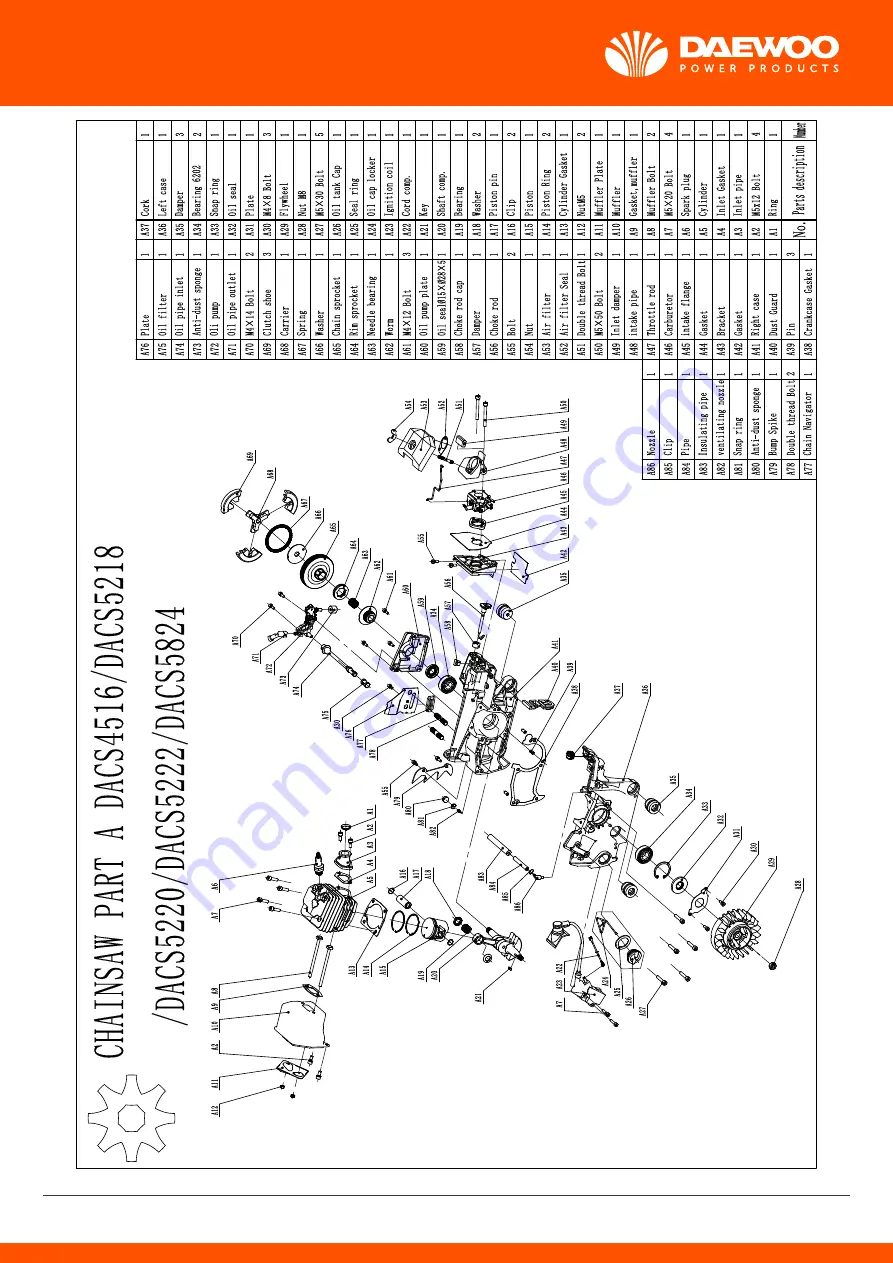

Summary of Contents for DCS Series

Page 21: ...www daewoopower bg 21 ...

Page 22: ...www daewoopower bg 22 ...

Page 43: ...www daewoopower bg 43 13 СХЕМА И СПИСЪК НА РЕЗЕРВНИТЕ ЧАСТИ ...

Page 45: ...www daewoopower bg 45 ...