g. Assemble the nozzle and nozzle hold-

er assembly to the nozzle tester and

zero the dial gauge.

h. Operate the nozzle tester, bleed the

retaining nut, and check for fuel leak-

age. (Figure 4-41)

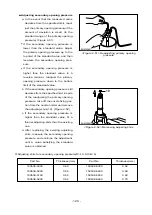

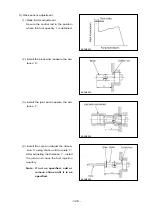

i. Operate the nozzle tester and increase

the tester pressure up to 350~450

kgf/cm

2

in order that the needle valve

can be fully lifted. Then, record the full

lift value "L". (Figure 4-42)

Note: This testing is to be made in

order to check the nozzle seat

portion for unusual wear or

whether the nozzle assembly is

a standard item.

- 116 -

EQM4047I

L

0

EQM4048I

Tester pressure

Amount of lift

<Figure 4-41> Air in the retaining nut

<Figure 4-42> Checking full lift of needle valve