•

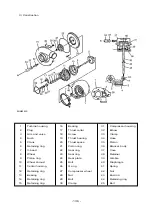

Retaining nut

a. Take out the dial gauge, nut, holder

and gasket from the cap nut(7).

b.

Remove the adjusting retaining nut

and gasket, and install the original

retaining ring nut(17:SW19mm).

(Figure 4-53)

Retaining nut tightening torque 59~78

N•m (6.0~8.0kgf•m)

- 132 -

EQM4036I

<Figure 4-53> Installing retaining nut

•

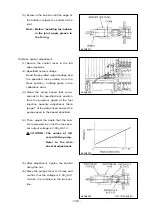

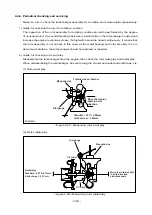

Inspection at completion

a. Assemble the nozzle holder to a nozzle

tester and check the primary opening

pressure, spray patterns, oil tightness

of seat portion, and oil leakage from

each part. (Figure 4-54)

0

20

40

60

80

100

EQM4059I

<Figure 4-54> Inspection at completion

b. When replacing the nozzle, replace it

with a new "nozzle service kit" integrat-

ed with a nozzle, lift piece, and spacer

as a complete set. (Figure 4-55)

Note: If only a nozzle is replaced, the

amount of pre-lift will deviate from

the specified value.

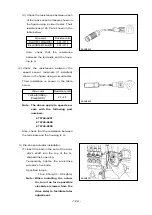

13

15

A

EQM4060I

<Figure 4-55> Nozzle, lift piece, and spacer