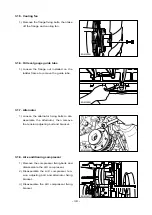

2.1.7. Valve clearance

1) Turn the crank shaft so that the piston in No. 1 cylinder reaches the TDC on compression

stroke, then adjust the valve clearance.

2) After releasing the lock nut for the rocker arm adjusting screw, insert a feeler gauge of speci-

fied thickness into the clearance between the rocker arm and valve stem, and adjust the

clearance with the adjusting screw. Fully tighten the lock nut when a correct adjustment is

obtained.

3) Carry out the same adjusting operation according to the firing order(1-5-3-6-2-4)

(Valve clearance(with engine cooled): 0.30mm for both intake and exhaust)

2.1.8. Cylinder compression pressure

1) Stop the engine after warming up, then remove the nozzle holder assembly.

2) Install a special tool(gauge adapter) in nozzle holder hole and mount the compression gauge

in position of the nozzle holder.

3) Cut off fuel circulation, rotate the starter, then measure compression pressure in each cylin-

der.

6

Testing conditions: Coolant temperature 20

C

, Engine speed, 200 rpm (10 turns)

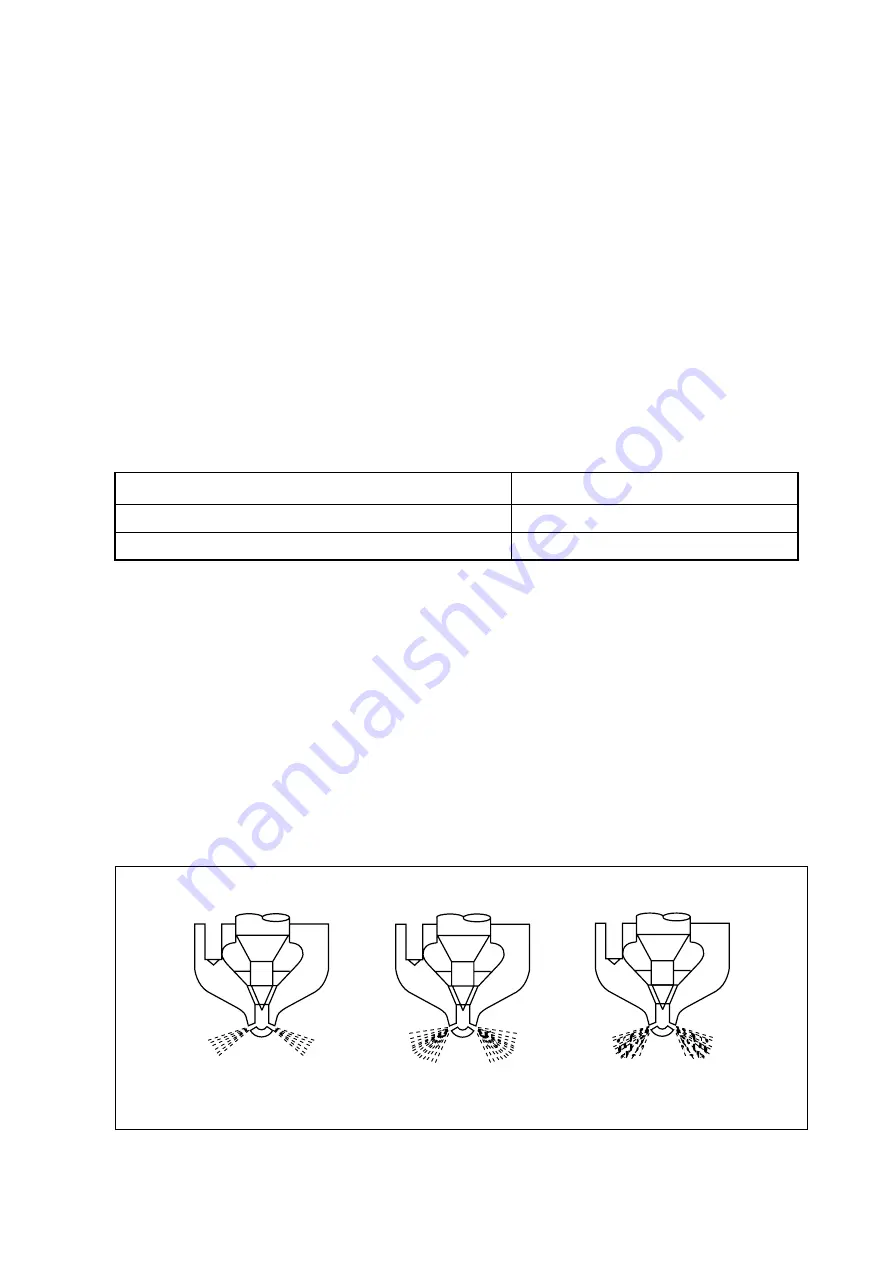

2.1.9. Injection nozzle

1) Assemble a nozzle to a nozzle tester.

2) Check injection pressure, and adjust the nozzle using the adjusting shim if the pressure does

not meet the specified limit.

3) Check nozzle spray patterns and replace if damaged.

Standard

28 kg/cm

2

over

Limit

24 kg/cm

2

or less

Difference between each cylinder

L

10% or less

- 24 -

Normal

Abnormal

Abnormal

<Figure 2-1> Nozzle spray patterns

EFM1006I