3.2.5. Cam shaft

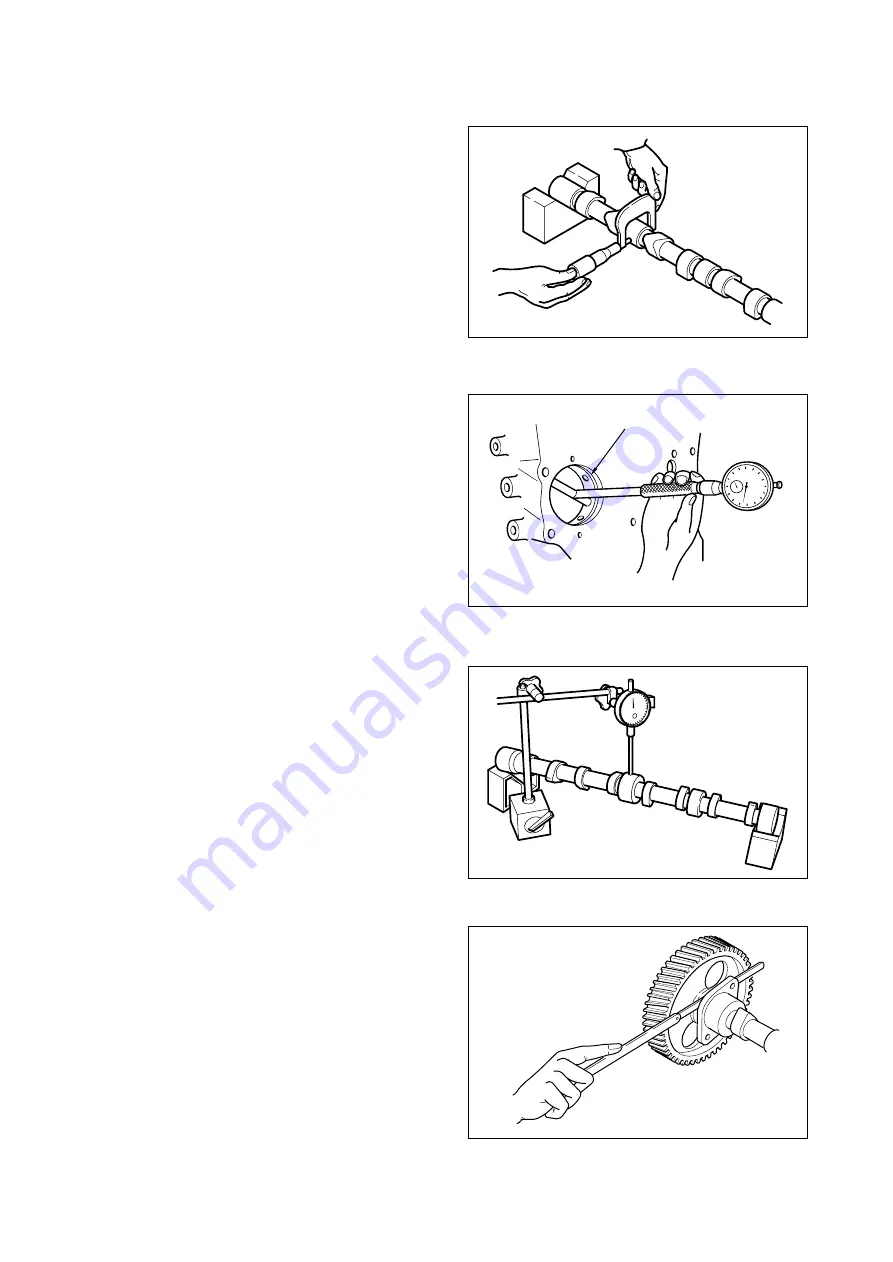

1) Inspection of cam

(1) Measure the cam height with a

micrometer and replace the camshaft

if the measured value is beyond the

specified limit.

(2) Inspect the cam face for scratch or

damage.

Slight step wear or damage on the

cam face may be corrected with oil

stone or oiled grinding paper. But,

replace if severely damaged.

- 53 -

EDM2045I

<Figure 3-8> Measuring cam height

2) Inspection of cam shaft

(1) With an outside micrometer, mea-

sure the camshaft journal diameter.

(2) Measure the inside diameter of the

camshaft bushing on the cylinder

block using a cylinder bore indicator,

and compare the measured value

with the camshaft outside diameter to

determine the clearance.

(3) Replace the bushing if the measured

value is beyond the specified limit.

(4) Support the cam shaft on two V-

blocks and check for run-out using a

dial indicator. Correct or replace the

cam shaft if the amount of run-out is

beyond the value indicating need for

servicing.

EAOM4063

<Figure 3-9> Measuring inside diameter of

cam shaft bushing on cylinder block

EFM2046I

<Figure 3-10> Measuring cam shaft run-out

3) Cam shaft end play

(1) Push the thrust plate toward the cam

gear.

(2) With a feeler gauge, measure the

clearance between the thrust plate

and cam shaft journal.

(3) If the end play is excessive, replace

the thrust plate.

EAOM4067

<Figure 3-11> Measuring cam shaft axial play

Cam bushing