(3) Conn. rod bearing crush can be

checked as follows:

Install the bearing and cap in the

conn. rod big end, retighten the bolts

to specified torque, unscrew out one

bolt completely, then measure the

clearance between the bearing cap

and conn. rod big end using a feeler

gauge.

- 57 -

EDM2049I

<Figure 3-21> Conn. rod bearing crush

4) Measurement of crank shaft end play

(1) Assemble the crankshaft to the cylin-

der block.

(2) With a dial gauge, measure crank

shaft end play.

EPM2018S

<Figure 3-22> Measuring crankshaft end play

3.2.8. Piston

1) Visually check the pistons for cracks,

scuff or wear, paying particular attention

to the ring groove.

2) Measurement of the clearance between

the piston and cylinder liner.

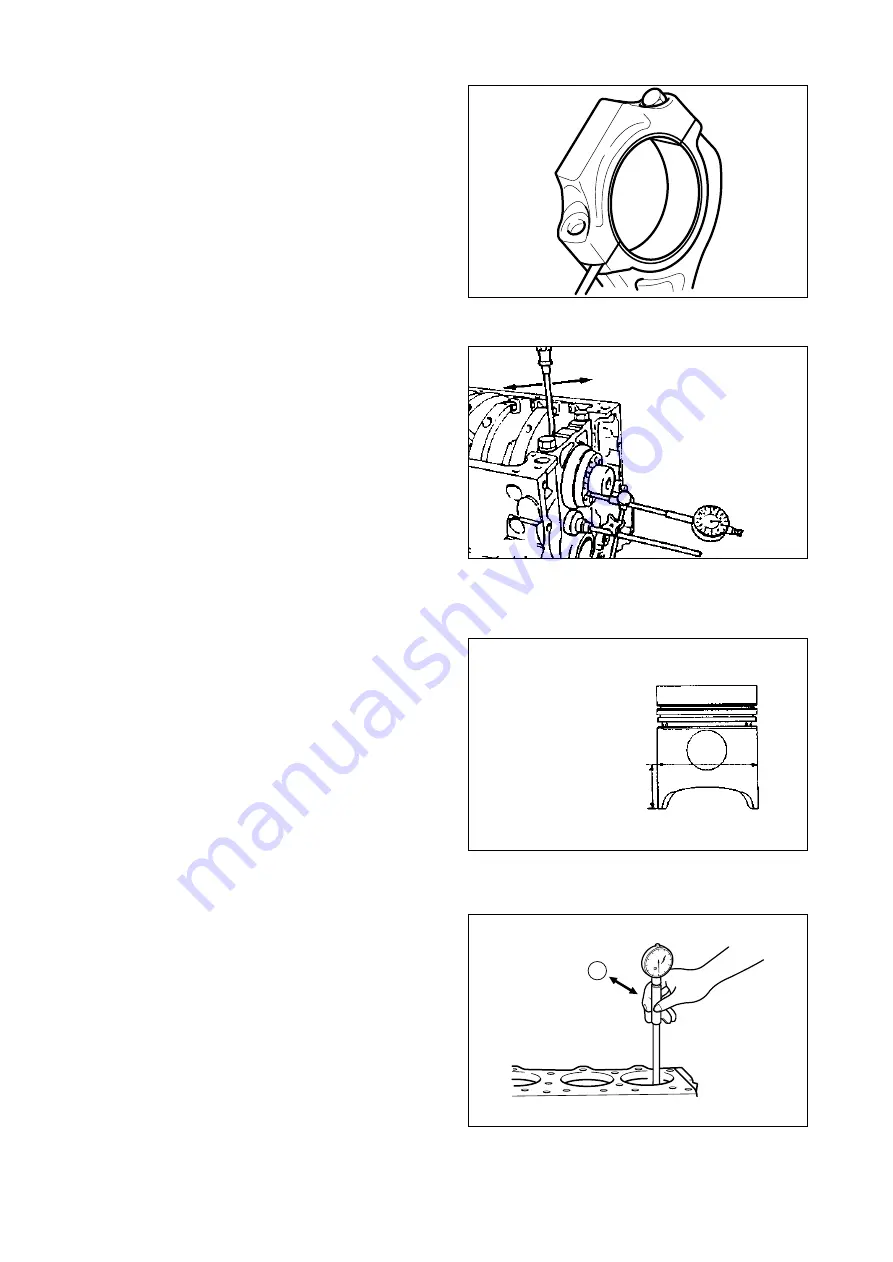

(1) With an outside micrometer, mea-

sure the piston outside diameter at a

point 18mm away from the lower end

of piston skirt in a direction at a right

angle to the piston pin hole.

EQM3051S

<Figure 3-23> Measuring piston outside

diameter

<Figure 3-24> Measuring cylinder liner inside

diameter

(2) Using a cylinder bore gauge, mea-

sure cylinder liner inside diameter at

3 points (cylinder top ring contacting

face, middle, and oil ring contacting

face on BDC) in a direction at an

angle of 45°. Take the mean value

with the largest and smallest values

excepted.

2

EQM3052I

Position of measuring

outside diameter