5. MAINTENANCE AND CARE

5.1. Periodical Inspection and Maintenance

In order to insure maximum, trouble-free engine performance at all times, regular inspection,

adjustment and maintenance are vital.

•

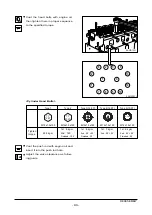

Daily inspections in below figure should be checked every day.

•

The maintenance should be executed thoroughly at regular internals.

( refer to appendix “General Engine Inspection Cycle”. )

5.2. Lubrication System

5.2.1. Exchanging of lubrication oil

Engine oil and the oil filter are important factors affecting engine life. They affect ease of starting,

fuel economy, combustion chamber deposits and engine wear.

At the end of the break-in period 1,000km (50hours), change the oil sump oil and replace the

oil filter cartridge.

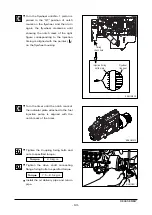

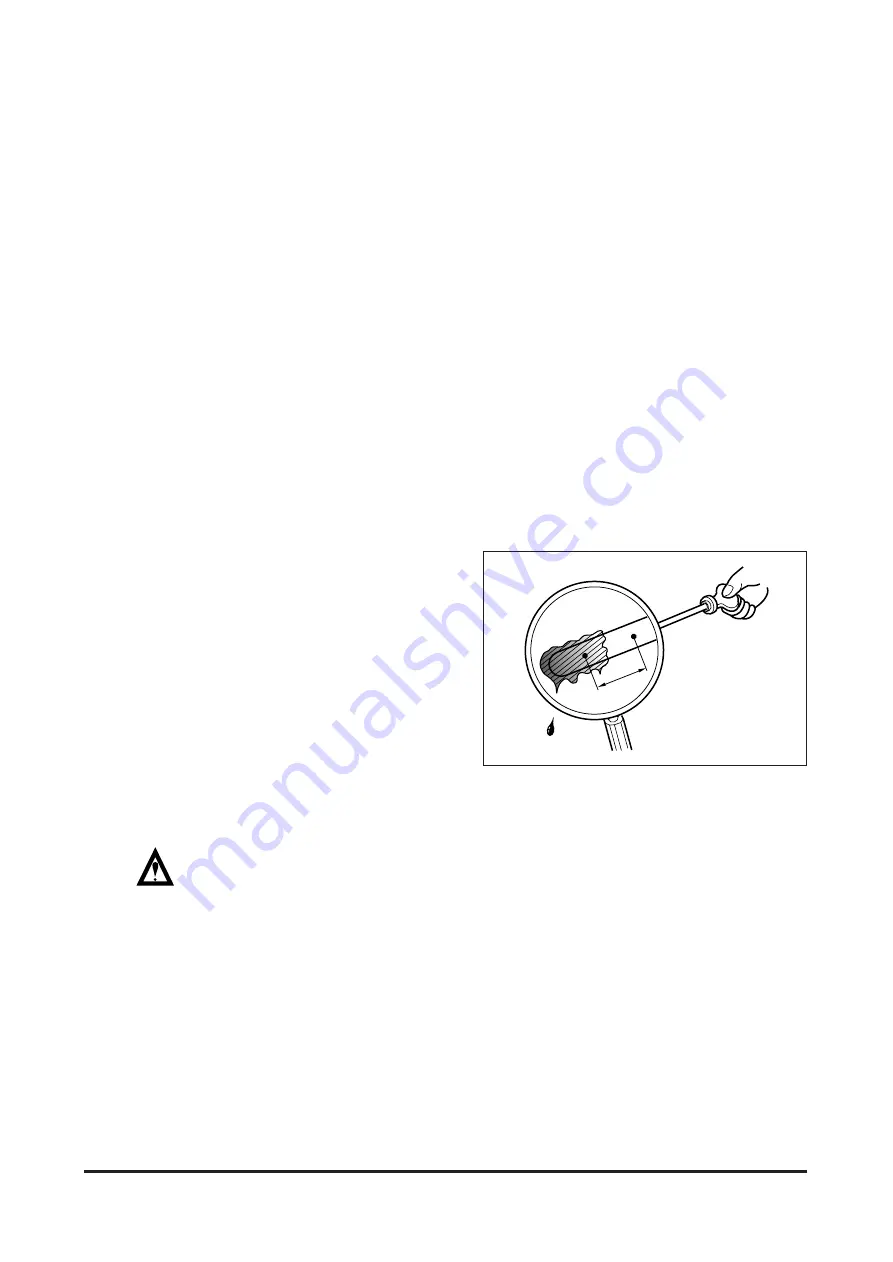

5.2.2. Oil level gauge

Check the oil level in the engine sump

daily with a oil level gauge.

•

The notches in oil level gauge must

indicate the oil level between the max.

and the min. permissible.

•

The oil level should be checked with the

engine horizontal and only after it has

been shut down for about 5 minutes.

•

Examining the viscosity and the

contamination of the oil smeared at the

oil level gauge replace the engine oil if

necessary.

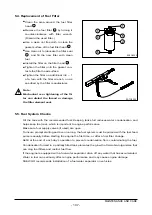

Caution :

Do not add so much engine oil that the oil level rises above the max. marking on

the oil level gauge. Over lifting will result in damage to the engine.

- 103 -

MAINTENANCE AND CARE

EA4O4001

Summary of Contents for DE12T

Page 2: ......

Page 187: ... Engine Assembly DE12TIS ECIEA 183 APPENDIX EE6OM026 ...

Page 188: ......