5.5.1. Fuel contamination and water trap

In the generator environment, the most likely fuel contaminants are water and microbial growth

(black “slime”). Generally, this type of contamination is the result of poor fuel handling practices.

Black “slime” requires water in the fuel to form and grow, so the best prevention is to keep water

content to a minimum in storage tanks.

If diesel fuel which contains moisture is used the injection system and the cylinder liners / pistons

will be damaged. This can be prevented to same extent by filling the tank as soon as the engine

is switched off while the fuel tank is still warm (formation of condensation is prevented). Drain

moisture from storage tanks regularly. Installation of a water trap upstream of the fuel filter is also

advisable.

Note :

A galvanized steel tank should never be used for fuel storage, because the fuel oil

reacts chemically with the zinc coating to form powdery flakes which can quickly clog

the fuel filters and damage the fuel pump and injection nozzles.

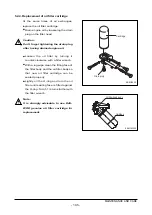

5.5.2. Priming pump strainer cleaning

Clean the priming pump strainer every

10,000km (200 hours) operation.

The strainer is incorporated in the priming

pump inlet side joint bolt.

Clean the strainer with the compressed

air and rinse it in the fuel oil.

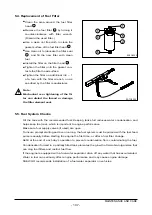

5.5.3. Bleeding the fuel system

After the cleaning of the fuel filter or

after the engine stop by the lack of fuel,

the bleeding of the fuel system must be

executed by all means.

Bleed the system by manually operating

the priming pump with fuel filter outlet

joint bolt and injection pump bleeder

screw loosened.

•

Press the feed pump cap repetitively

until the fuel without bubbles comes out

from the bleeding valves.

•

After the whole air is pulled out, close the valve of the filter.

•

Confirm the resistance of fuel delivery by the repetition pressing of the feed pump cap,

Pressure and turn the feed pump cap simultaneously to close it.

- 108 -

MAINTENANCE AND CARE

EE6OM016

Strainer (Inner)

EE6OM017

Priming pump

Summary of Contents for DE12T

Page 2: ......

Page 187: ... Engine Assembly DE12TIS ECIEA 183 APPENDIX EE6OM026 ...

Page 188: ......