2) 1-spring type (DE12T)

(1) Disassembly

1. Cap nut

2. Adjusting screw

3. Spring

4. Push rod

5. Connector

6. Retaining nut

7. Needle valve

8. Nozzle

9. Nozzle holder

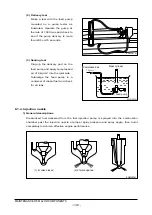

(2) Reassembly

•

After removing carbon deposit, sub-

merge the nozzle in diesel oil and

clean it.

•

Replace all the gaskets with new

ones.

•

Assemble the parts and tighten them

to specified torque.

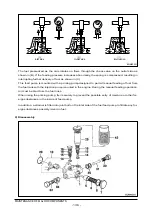

(3) Adjustment

•

Remove the cap nut and assemble a noz-

zle to a nozzle tester.

•

With the adjusting screw loosened, oper-

ate the nozzle 2 ~ 3 times to bleed it.

•

Operate the nozzle tester lever at the

specified rate.

•

Adjust the injection pressure to the stan-

dard pressure by spring tension shims.

•

After adjusting the injection pressure,

tighten the cap nut to specified torque.

•

Re-check the injection pressure and see if

the spray pattern is normal.

- 139 -

MAINTENANCE OF MAJOR COMPONENTS

EA0M3003

EQM4025S

EQM4026S

Summary of Contents for DE12T

Page 2: ......

Page 187: ... Engine Assembly DE12TIS ECIEA 183 APPENDIX EE6OM026 ...

Page 188: ......