3.2.10. Piston pin

1) Wear

•

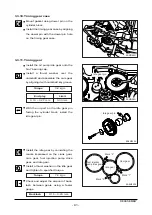

Measure the amount of wear on the

piston pin at the points as shown.

•

If the measured values are beyond

the limit (0.005 mm or greater),

replace the pin.

2) Clearance

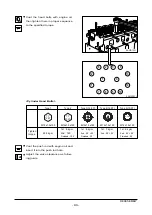

•

Measure the clearance between the

piston pin and connecting rod bush-

ing, and replace either of them,

whichever damaged more, if the

measured value is beyond the limit.

3) Condition check

•

Check the engaged condition of the

piston and piston pin. If it is possible

to force the pin into the piston heated with piston heater, the piston is normal.

When replacing the piston, be sure to replace the piston pin together.

3.2.11. Connecting rod

1) Distorsion

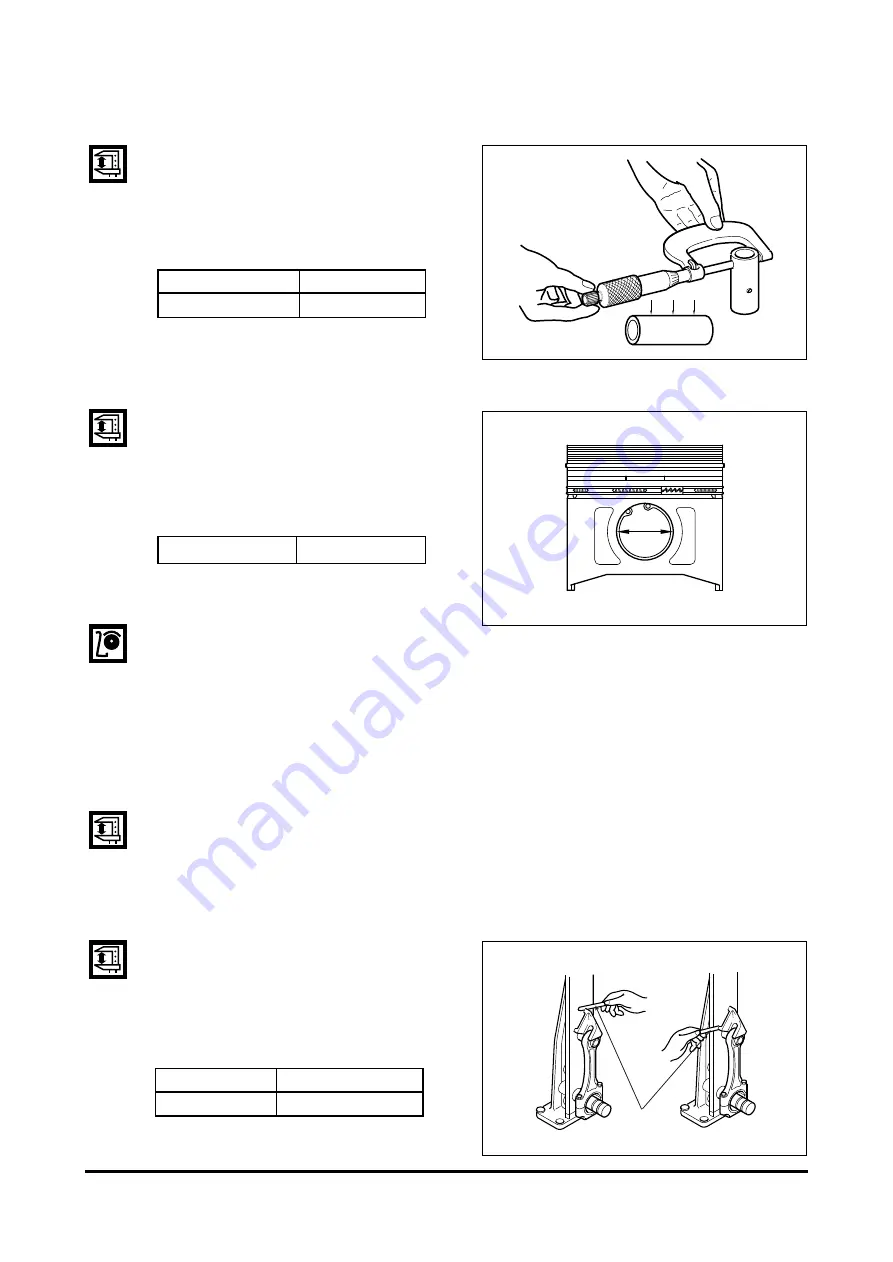

•

Check the connecting rod for distortion.

•

As shown in the figure below, install the connecting rod to the connecting rod tester, and

check for distortion using a feeler gauge.

•

If the connecting rod is found distorted, never re-use it but replace with a new one.

2) Holes alignment (parallelism)

•

Measure the alignment of the con-

necting rod small bushing hole with

connecting rod big end hole.

•

At this time also, use both connecting

rod tester and feeler gauge.

- 74 -

INSPECTION AND MEASUREMENT

EA0M4031

EA3M2047

Standard

Limit

N

44.995 ~

N

45.0 mm

N

44.990 mm or less

Standard

Limit

0.05 mm

0.1 mm or less

Limit

0.011 mm

EA0M4034

간극 게이지

feeler

gauge

Summary of Contents for DE12T

Page 2: ......

Page 187: ... Engine Assembly DE12TIS ECIEA 183 APPENDIX EE6OM026 ...

Page 188: ......