www.daewoopower.bg

41

BG

13.

ДЕКЛАРАЦИЯ ЗА СЪОТВЕТСТВИЕ

/ DECLARATION OF CONFORMITY

CE DECLARATION OF CONFORMITY /

ЕС

ДЕКЛАРАЦИЯ

ЗА

СЪОТВЕТСТВИЕ

(EN) Lawn mower 150

СС, 2

.6 kW

, 460 mm

MODELS:

DLM4600SPL (DM46S

-D150)

We GBR Corp. LTD,

15/

F. 100 Queen’s Road Central, Central, Hong Kong, declare under our sole responsibility

that this product is in conformity and accordance with the following standards and

The under-

signed is responsible for the

of technical

(BG)

Косачка бензинова самоходна 1

50

СС, 2

.6 kW

, 460 mm

МОДЕЛИ:

DLM4600SPL (DM46S

-D150)

Ние,

GBR

address:

15/

F. 100 Queen’s Road Central, Central, Hong Kong,

декларираме

на

собст

-

вена

отговорност

,

че

този

продукт

е

в

съответствие

с

изброените

по-долу

стандарти

и

разпоредби.

Долуподписаният

е

отговорен

за

съставянето

на

техническа

документация.

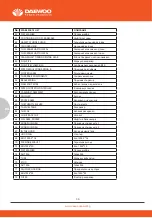

Harmonized standards/

Хармонизирани стандарти:

EN ISO 5359-1:2013

EN ISO 5395-2:2013

/

A2:2017

Machinery

Машинни

директиви

2006/42/

EC

Noice emission in the environment by equpment for use outdoors

/

Шумови

емисии

на

съоръжения,

предназначени

за

употреба

извън

сгради

2000/14/ЕC

The undersigned is responsible for the compila

�on

of technical documenta

�on.

Долуподписаният

е

отговорен

за

съставянето

на

техническа

документация

.

Signature and stamp on undersigned responsible:

Date and place:

September, 2021

Hong Kong

Summary of Contents for DLM4600SPL

Page 19: ...www daewoopower bg 19 BG 1 20 2 21 3 22 4 22 5 22 6 23 7 25 8 27 9 28 10 30 11 33 12 34 13 41...

Page 40: ...www daewoopower bg 40 BG 10 6 M5x30 10 6 M5x30...

Page 43: ...www daewoopower bg 43 BG 24 6 6 12 6...

Page 44: ...www daewoopower bg 44 BG 1 1 2022 6 6...

Page 45: ...www daewoopower bg 45 BG...

Page 46: ...www daewoopower bg 1784 1 51 359 2 81 77 600 359 2 81 77 601...