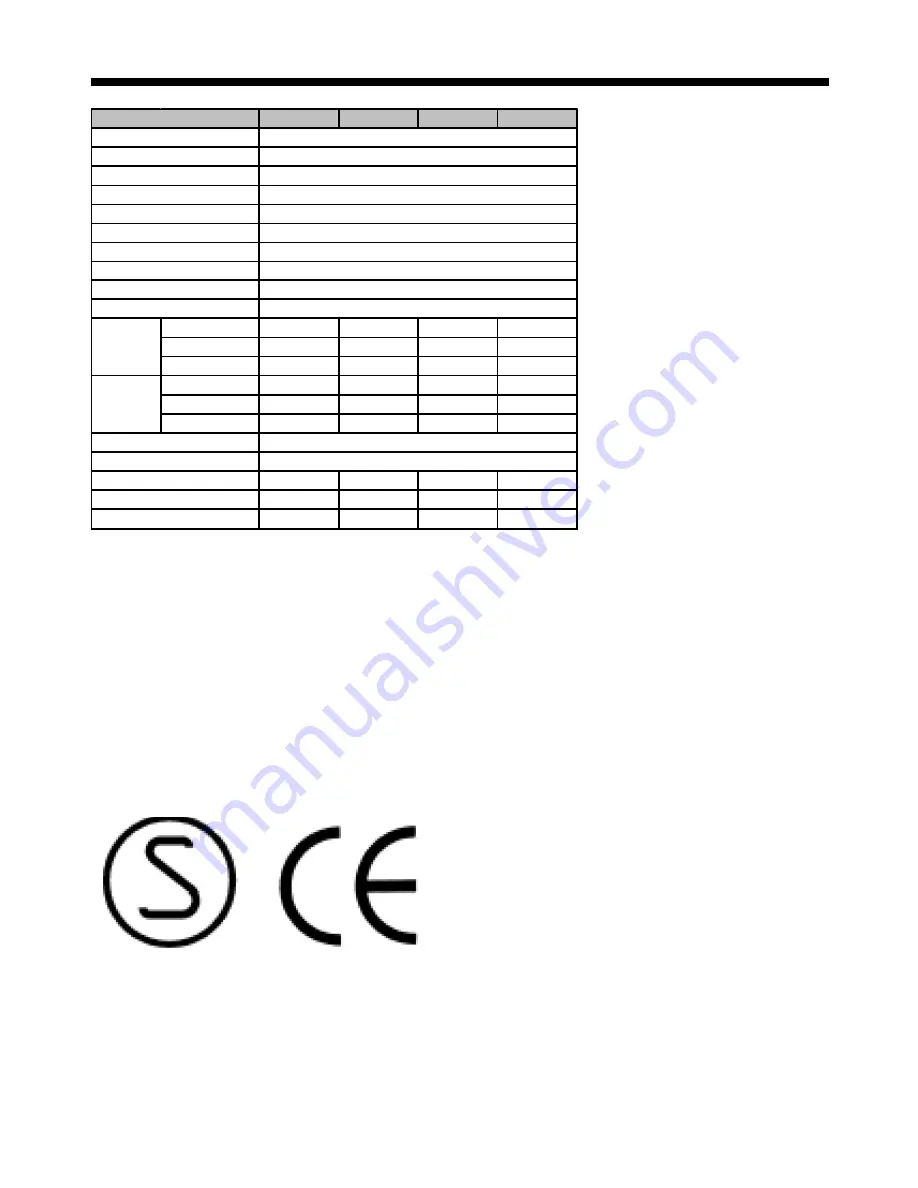

1. SPECIFICATIONS

REMARKS:

* Dept exception handle

1.2. Types of the approved safety standars

366MNL

386MNL

396MNL

416MNL

Freezer

94

109

94

109

Refrigerator

218

218

252

252

Total

312

327

346

361

Height

1765

1854

1896

1985

Width

600

600

600

600

Depth *

642

642

642

642

* ***

* ***

* ***

* ***

N

N

N

N

69

71

71

74

MECHANIC TYPE

R-134A

100 grs

KPC CBE-140L5Z

180

15

Rated input (W)

Defrost system

Compressor

C-PENTANE

Fan cooling system

Automatic start & Automatic stop system

AC220~240V / 50Hz

5

A

External

dimension

(mm)

Lamp rated input (W)

Gross

capacity

(liter)

Energy class

Division

Model name

Cooling system

Blowing agent

Refrigerant type

Rated voltage

Refrigerant Q´ty

Net weight (kg)

Freezing capacity(kg/24h)

Climate class

Star rating

2

Summary of Contents for ERF-366MNL

Page 5: ...3 REAL VIEW 4...

Page 6: ...4 MACHINE ROOM VIEW 5 SCREW MACHINE...

Page 7: ...5 REFRIGERANT CYCLE 6 CAPILLARY TUBE...

Page 8: ...6 WIRING DIAGRAM 7...

Page 15: ...9 EXPLODE DRAWING 14...

Page 16: ...15...