8

2-2-1) PERIODIC MAINTENANCE AND SERVICE SCHEDULE

A. In order to effectively maintain the excellent performance and fully utilize the features of this apparatus,

and to lengthen the life of the mechanism and tapes, we strongly urge you to perform periodic

maintenance and inspection, as described below.

¡

After repairing, do the maintenance described below, irrespective of the length of time in use.

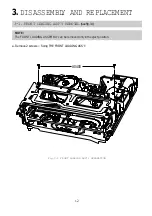

B. Cleaning of the Head Drum Ass'y

ƒ¡

Clean the Drum assembly with a cleaning cloth soaked in liquid cleaner (alcohol) by placing lightly

against the Drum and slowly revolving the rotating HEAD DRUM Ass'y by hand (Do not rotate the

upper Drum by applying electric power to the motor when cleaning).

ƒ¡

Do not move the cleaning cloth in the vertical direction against the heat-tip.

C. Cleaning the tape transporting section.

ƒ¡

Clean the tape transporting parts with a cleaning cloth soaked in alcohol.

D. Cleaning of driving section

ƒ¡

Clean the driving section with a cloth soaked in alcohol.

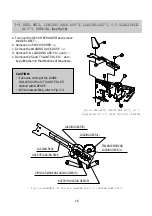

E. Routine inspection

ƒ¡

Perform maintenance and inspection as separately described depending on the period of time in

use.

ƒ¡

Refer to the table of 2-2-3.

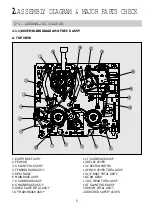

2-2-2) CLEANING AND LUBRICATION

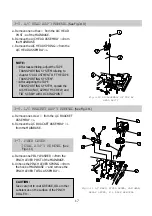

A. Cleaning of Tape Transporting section and Driving section

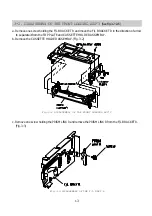

a. Cleaning of Tape Transporting section

ƒ¡

The following parts should be cleaned after every 500 hours of use.

ƒU

TENSION POLE

ƒU

S SLANT POLE

ƒU

AC HEAD/AE HEAD

ƒU

S GUIDE POST

ƒU

VIDEO HEAD/DRUM

ƒU

T GUIDE POST

ƒU

FE HEAD

ƒU

T SLANT POLE

ƒU

CAPSTAN SHAFT

ƒU

S GUIDE ROLLER

ƒU

T GUIDE ROLLER

ƒU

PINCH ROLLER

ƒU

VERTICAL POST

ƒ¡

As the above parts contact with the video tape, they tend to collect dust particles. If they are stained

with dust or foreign substance it has a bad effect on the picture and may lead to damage of the tape.

ƒ¡

After cleaning with alcohol, allow the parts to dry thoroughly before using a cassette tape.

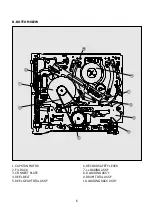

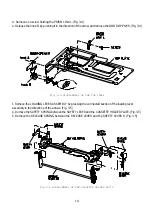

b. Cleaning of Driving section

ƒU

REEL TABLE

ƒU

CAPSTAN FLYWHEEL/PULLEY

ƒU

REEL PULLEY

B. LUBRICATION

ƒU

S REEL POST

ƒU

T REEL TABLE POST

ƒU

REEL GEAR POST

ƒ¡

After cleaning these parts with alcohol, lubricate these with one or two drops of oil.

2-2. PERIODIC MAINTENANCE AND SERVICE SCHEDULE

Summary of Contents for K-MECHA DECK

Page 1: ......

Page 4: ...3 1 2 1 WIRE DIAGRAM 1 2 WIRE DIAGRAM ...

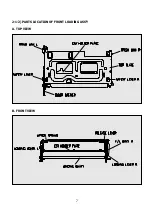

Page 8: ...7 2 1 2 PARTS LOCATION OF FRONT LOADING ASS Y A TOP VIEW B FRONT VIEW ...

Page 38: ...37 6 EXPLODED VIEW AND PA RTS LIST 6 1 EXPLODED VIEW OF DECK ASS Y TOP VIEW AC001 ...

Page 39: ...38 6 2 EXPLODED VIEW OF DECK ASS Y BOTTOM VIEW ...

Page 40: ...39 6 3 EXPLODED VIEW OF F L ASS Y ...

Page 41: ...40 ...

Page 48: ...S022GBB ...