Summary of Contents for K30

Page 4: ...3 1 2 1 WIRE DIAGRAM 1 2WIREDIAGRAM ...

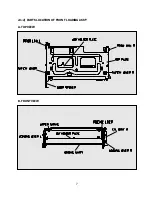

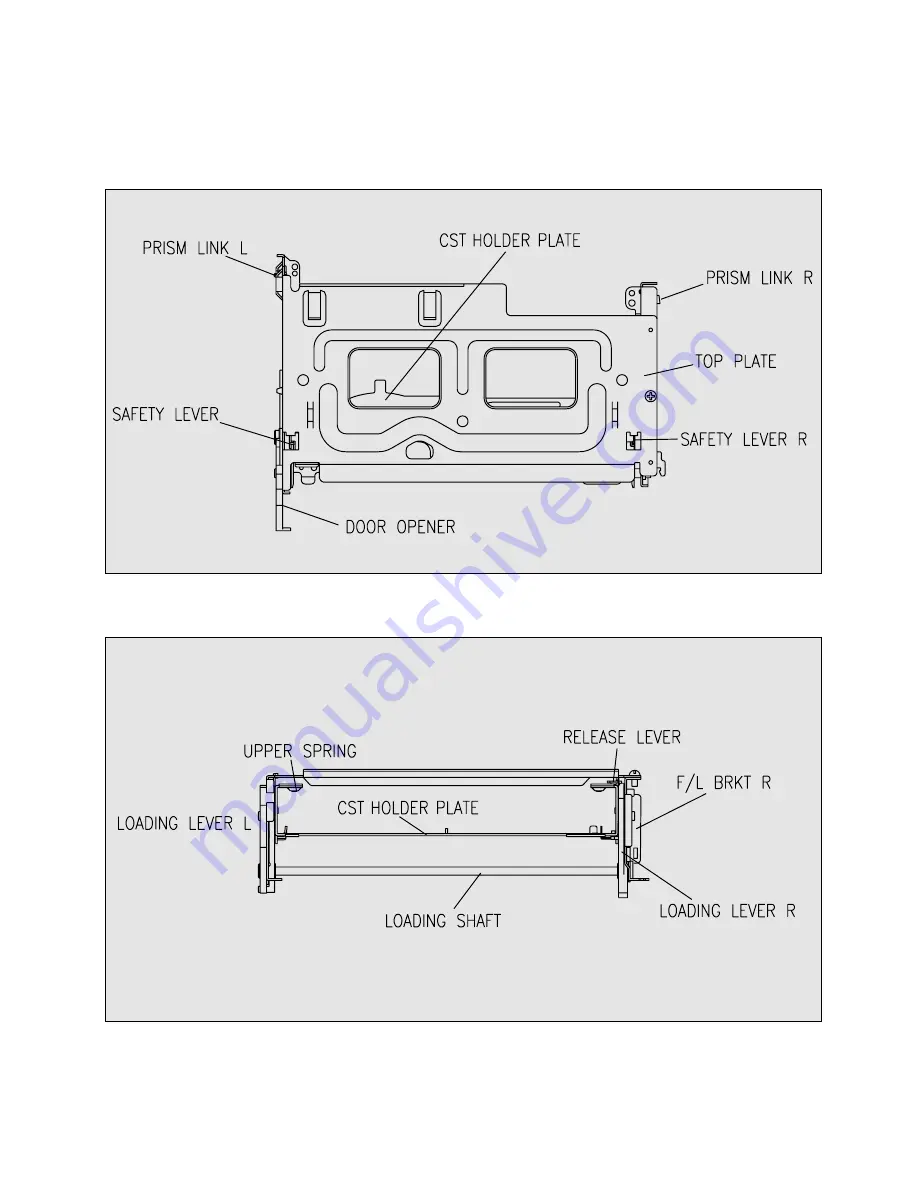

Page 8: ...7 2 1 2 PARTS LOCATION OF FRONT LOADING ASS Y A TOP VIEW B FRONT VIEW ...

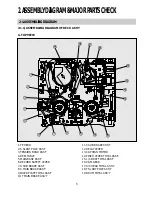

Page 38: ...37 6 EXPLODED VIEW AND PARTS LIST 6 1 EXPLODED VIEW OF DECK ASS Y TOP VIEW ...

Page 39: ...38 6 2 EXPLODEDVIEWOFDECKASS Y BOTTOMVIEW ...

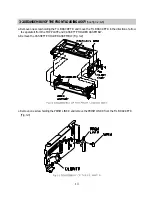

Page 40: ...39 6 3 EXPLODEDVIEWOFF LASS Y ...

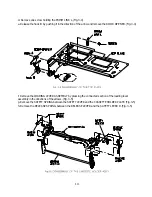

Page 41: ...40 D0040 D0020 D0050 D0010 D0080 D0090 D0060 D0070 D0040 ...