8

OPERATIONS AND FUNCTIONS

1. Connect the main lead to an electrical outlet.

2. After placing the food in a suitable container, open the oven door and put it on the glass tray. The glass tray must

always be in place during cooking.

3. Close the door securely.

4. The oven door can be opened at any time during operation by touching the door release button on the control

panel.

The oven will automatically shut off. To restart the oven, close the door and then touch START.

5. Each time a pad is touched, a BEEP will sound to acknowledge the touch.

6. The oven automatically cook on full power unless set to a lower power level.

7. The display will show :0 when the oven is plugged in.

8. Time clock returns to the present time when the cooking time ends.

9. When the STOP/CLEAR pad is touched during the oven operation, the oven stops cooking and all information

retained.

To erase all information (except the present time), touch the STOP/CLEAR pad once more. If the oven door is

opened during the oven operation, all information is retained.

10. If the START pad is touched and the oven does not operate, check the area between the door and door is closed

securely. The oven will not start cooking under the door is completely closed or the program has been reset.

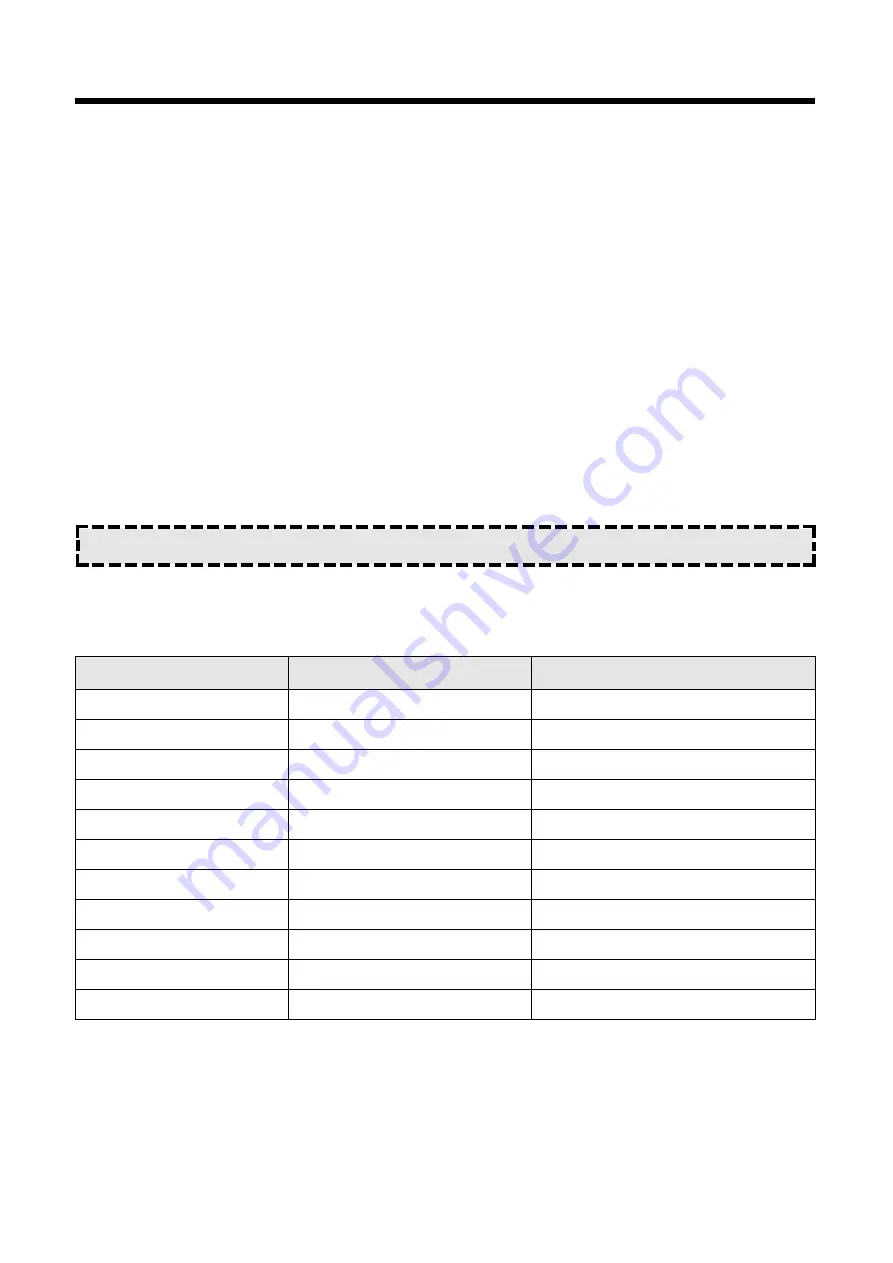

Wattage output chart

The power level is set by pressing the POWER pad. The chart shows the display, the power level and the percentage

of power.

Make sure the oven is properly installed and plugged into the electrical outlet.

Touch POWER pad.

Power level (Display)

Approximate Percentage of Power

Once P-HI

100

%

Twice P-90

90

%

3 times

P-80

80 %

4 times

P-70

70 %

5 times

P-60

60 %

6 times

P-50

50 %

7 times

P-40

40 %

8 times

P-30

30 %

9 times

P-20

20 %

10 times

P-10

10 %

11 times

P-00

0 %

Summary of Contents for KOR-164H0A

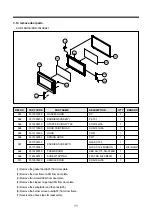

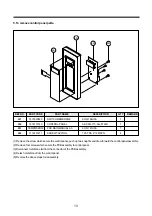

Page 5: ...4 EXTERNAL VIEW 1 OUTER DIMENSION ...

Page 25: ...24 WIRING DIAGRAM ...

Page 27: ...26 ...

Page 29: ...28 2 PCB CIRCUIT DIAGRAM ...