K1000896E Operation and Maintenance Manual

Inspection, Maintenance and Adjustment 4-31

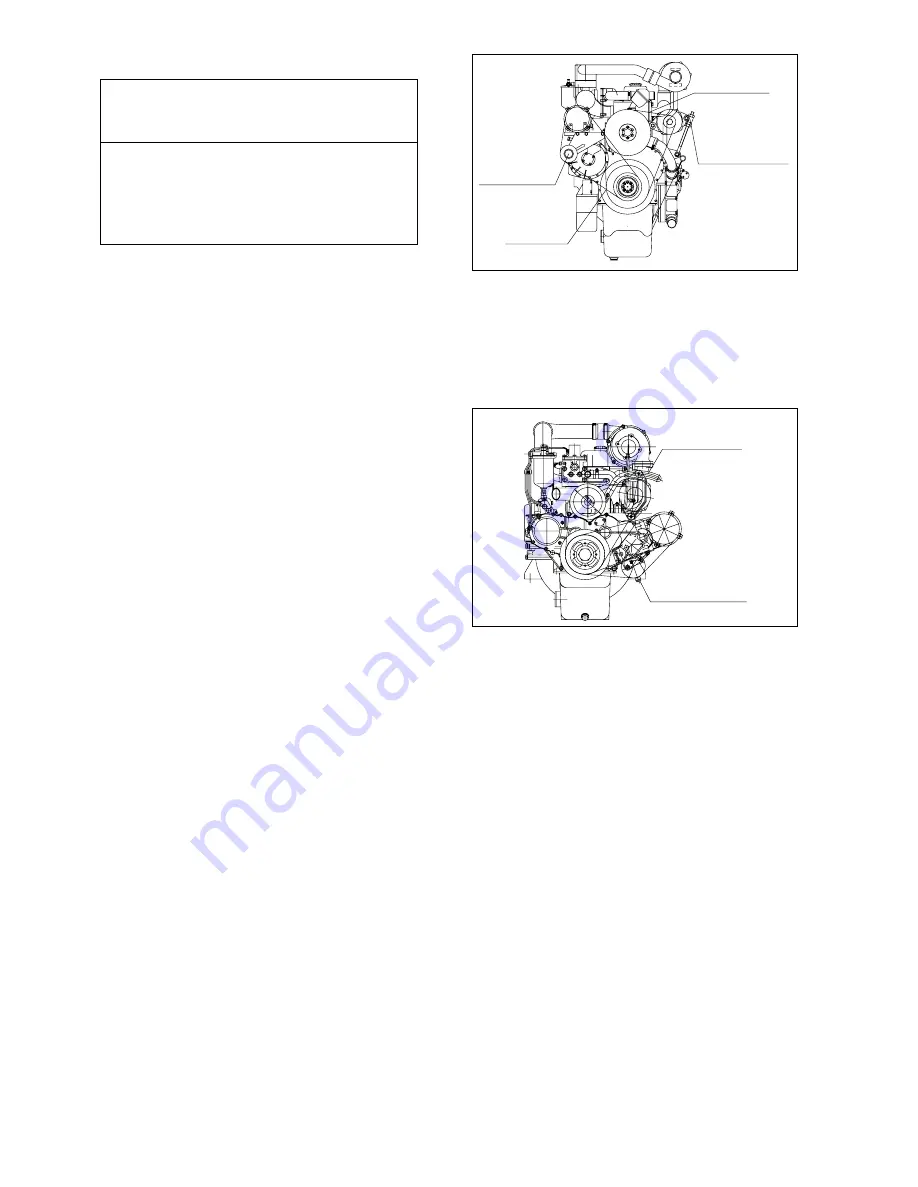

CHECK WATER PUMP BELT TENSION

NOTE:

Water pump belt tension must

be checked after first 50 hours

of operation to comply with new

machine break-in requirements.

After first tension check, belt

must be checked every 250

hours.

1.

Apply 10 kg (22 lb) of force to midpoint of

belt. (Figure 55 and Figure 56). The belt

should deflect 10 mm (0.4"). If belt deflects

more than this, loosen control link to

tighten belt tension until deflection is

10 mm (0.4"). Inspect belt for damage. If

belt is damaged, replace it.

IMPORTANT

A loose water pump belt can cause

engine overheating, poor charging, and/or

premature belt wear. A belt that is too

tight can cause damage to the water

pump, alternator bearing or belt.

Air-con belt

Adjustable link

for Air-con belt

Water pump belt

Adjustable link

for alternator belt

AOO0100L

Figure 55

(S/N 3001 thru 4000)

Adjustable link

for alternator belt

APO0090L

Air-con belt tension

control link (B)

Water pump belt tension

control link (A)

Figure 56

(S/N 4001 and Up)

Summary of Contents for Mega 250-V

Page 2: ......

Page 6: ......

Page 32: ......

Page 110: ......

Page 184: ......

Page 199: ...K1000896E Operation and Maintenance Manual Troubleshooting 6 13...

Page 200: ...6 14 Troubleshooting K1000896E Operation and Maintenance Manual...

Page 208: ......