1-16 Safety

K1000896E Operation and Maintenance Manual

TAKE TIME TO PROVIDE GOOD VISIBILITY

Halt work if visibility is poor. Strong rains, snow, fog and extremely dusty conditions can all obscure visibility

so badly that it is best to wait for weather to change or dust to settle before continuing operation.

Night work in areas of limited visibility should be halted if installation of extra work lights on machine (or

work area) is necessary.

Keep dirt and dust off of windows and off lens surfaces of work lights. Stop working if lights, windows or

mirrors need cleaning or adjustment.

FUEL, OIL AND HYDRAULIC FLUID FIRE

HAZARDS

Add fuel, oil, antifreeze and hydraulic fluid to

machine only in a well ventilated area. Machine

must be parked with controls, lights and

switches turned "OFF." Engine must be "OFF"

and any flames, glowing embers, auxiliary

heating units or spark causing equipment must

be doused, turned "OFF" and/or kept well clear

of machine.

Static electricity can produce dangerous sparks

at fuel filling nozzle. In very cold, dry weather or

other conditions that could produce static

discharge, keep tip of fuel nozzle in constant

contact with neck of fuel filling nozzle, to provide

a ground.

Keep fuel and other fluid reservoir caps tight

and do not start engine until caps have been

secured.

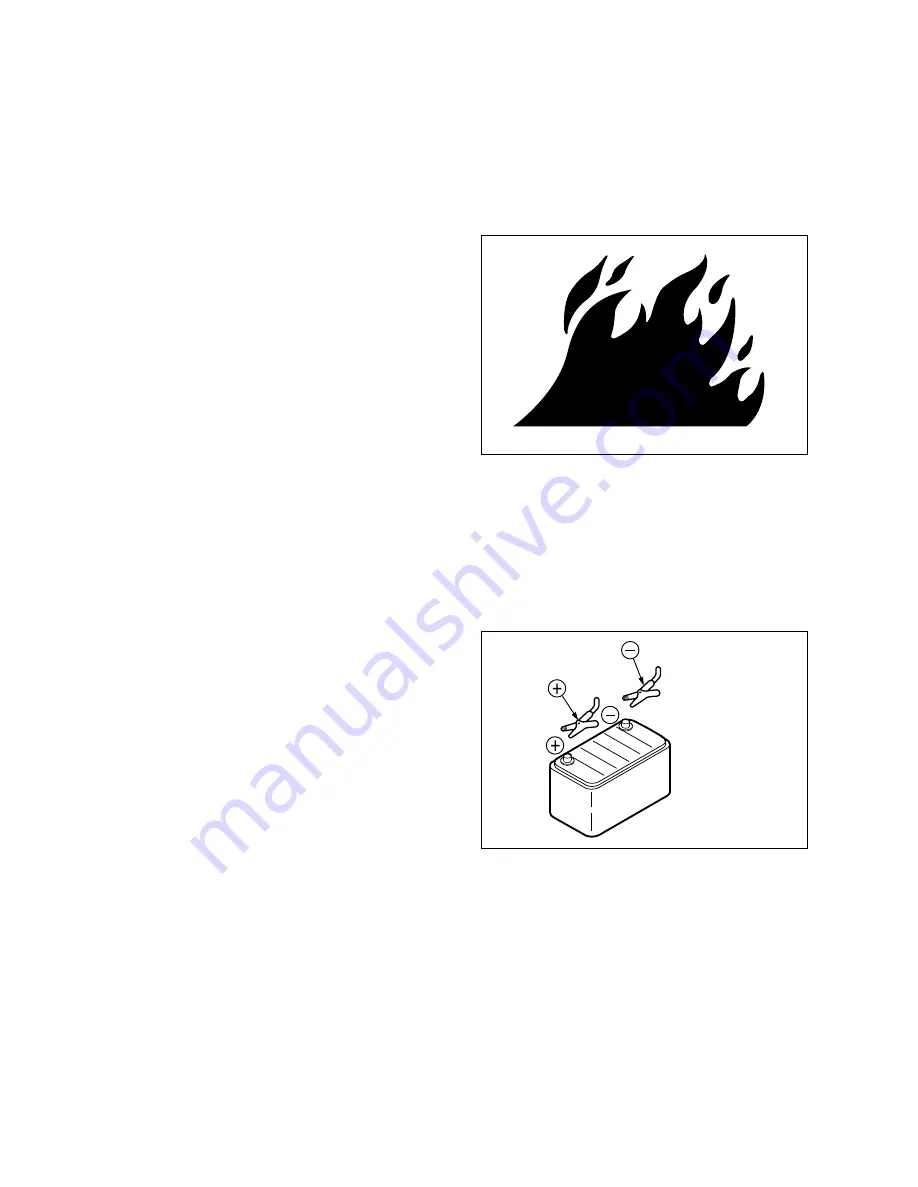

BOOST STARTING OR CHARGING ENGINE

BATTERIES

Turn "OFF" all electrical equipment before

connecting leads to battery. This includes

electrical switches on battery charger or boost

starting equipment.

When boost starting from another machine or

vehicle do not allow two machines to touch.

Wear safety glasses or goggles while required

parallel battery connections – positive to

positive and negative to negative – are made.

24 volt battery units consisting of two series

connected twelve volt batteries have a cable

connecting one positive terminal on one of the

12 volt batteries to a negative terminal on the other battery. Booster or charger cable connections must be

made between nonseries connected positive terminals and between negative terminal of booster battery

and metal frame of machine being boosted or charged. Refer to procedure and illustration in “Starting with

Auxiliary Batteries” on page 3-8.

Connect positive cable first when installing cables and disconnect negative cable first when removing

them. Final cable connection, at metal frame of machine being charged or boost started, should be as far

away from batteries as possible.

HAOA120L

Figure 10

HAOA310L

Figure 11

Summary of Contents for Mega 250-V

Page 2: ......

Page 6: ......

Page 32: ......

Page 110: ......

Page 184: ......

Page 199: ...K1000896E Operation and Maintenance Manual Troubleshooting 6 13...

Page 200: ...6 14 Troubleshooting K1000896E Operation and Maintenance Manual...

Page 208: ......