3.3. Reassembly

3.3.1. General precautions

•

Wash clean all the disassembled parts, particularly oil and water ports, using compressed air,

then check that they are free from restrictions.

•

Arrange the general and special tools in order for engine assembly operation.

•

To wet each sliding part, prepare the clean engine oil.

•

Prepare service materials such as sealant, gaskets, etc.

•

Discard used gaskets, seal rings, and consumable parts, and replace with new ones.

•

Apply only the specified torque for bolts in the specified tightening order and avoid over-tight-

ening.

•

Be sure to check that all the engine parts operate smoothly after being reassembled.

•

Check the bolts for looseness after preliminary reassembly.

•

After completing the engine reassembly operation, check if there is missing parts or shortage

of parts.

•

Keep your hands clean during the working.

3.3.2. Cylinder block

Cover the floor of the workshop with wood plate or thick paper to prevent damage to the

cylinder head and place the cylinder block with the head fitting surface facing downward.

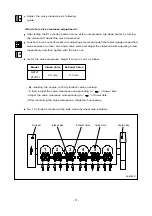

3.3.3. Oil spray nozzle

Tighten and assemble the oil spray nozzle

flange with fixing bolts using the spray noz-

zle jig.

3.3.4. Tappet and cam shaft

•

Undercool a new bush with dry ice for

about 2 hours and press it into position in

the cylinder block using a bench press.

After the pressing operation, measure

the inside diameter of the cam bush to

check if it is not deformed.

- 58 -

EDM3053I