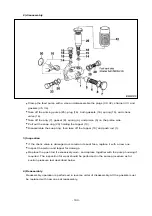

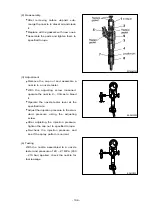

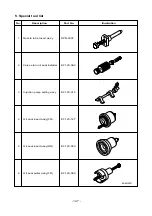

f. Install the dial gauge on the holder assem-

bly so that the pin is brought into contact

with the upper end of the push rod, then fix

the pin with the nut.

Note 1 : Fix the dial gauge so that a

stroke of 2 mm or so can be mea-

sured.

Note 2 : Overtightening the nut may

cause a sticking of the dial gauge

seat.

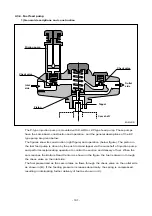

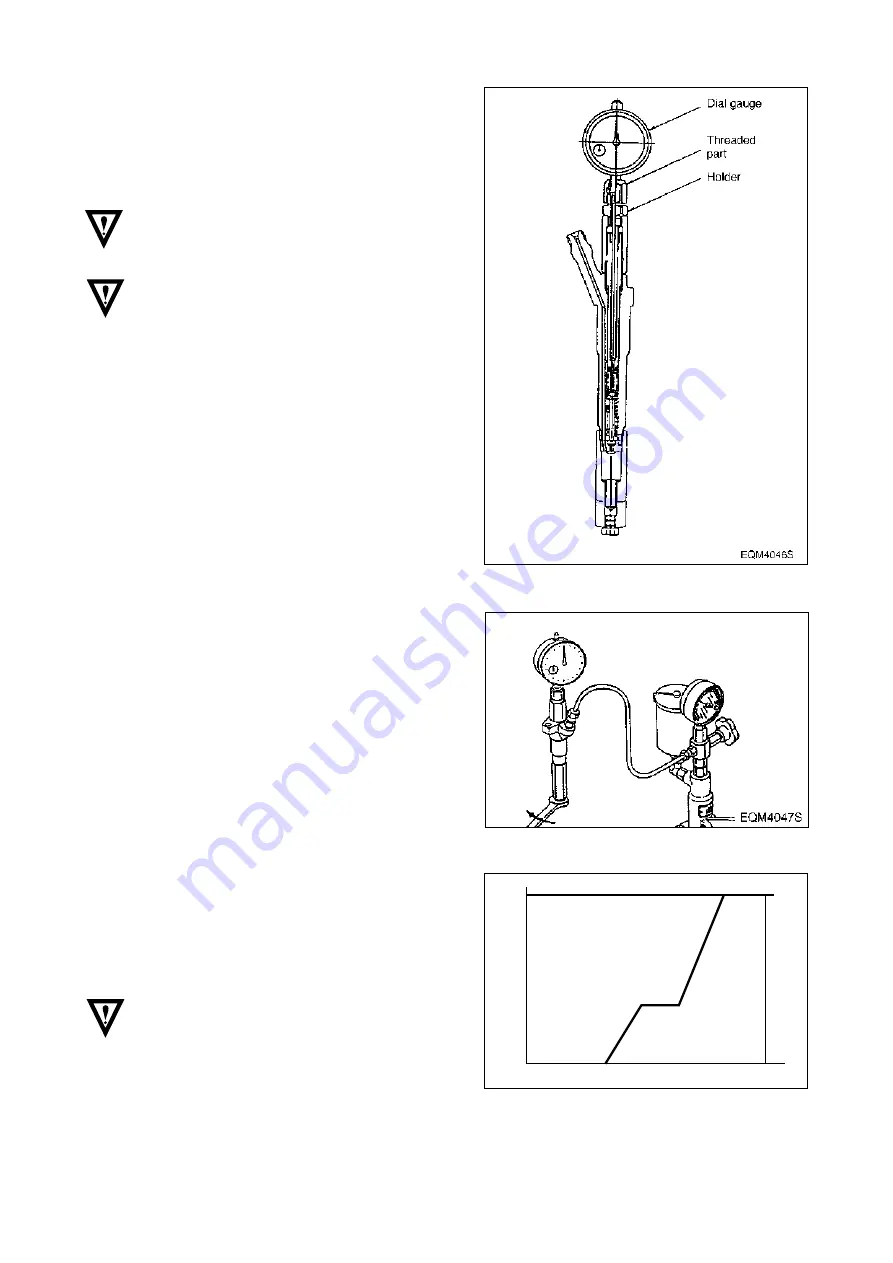

g. Assemble the nozzle and nozzle holder

assembly to the nozzle tester and zero the

dial gauge.

h. Operate the nozzle tester, bleed the retain-

ing nut, and check for fuel leakage.

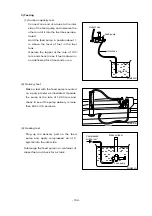

I. Operate the nozzle tester and increase the

tester pressure up to 350 ~ 450kgf•cm

2

in

order that the needle valve can be fully lift-

ed. Then, record the full lift value “L”.

Note : This testing is to be made in order

to check the nozzle seat portion for

unusual wear or whether the nozzle

assembly is a standard item.

- 112 -

L

0

EQM4048I