4.4.4. Precautions for operation

1) Precautions for operation of engine

The following precautions should be observed when starting, operating, or stopping the

engine:

- 122 -

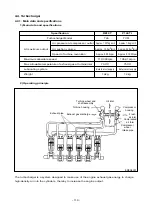

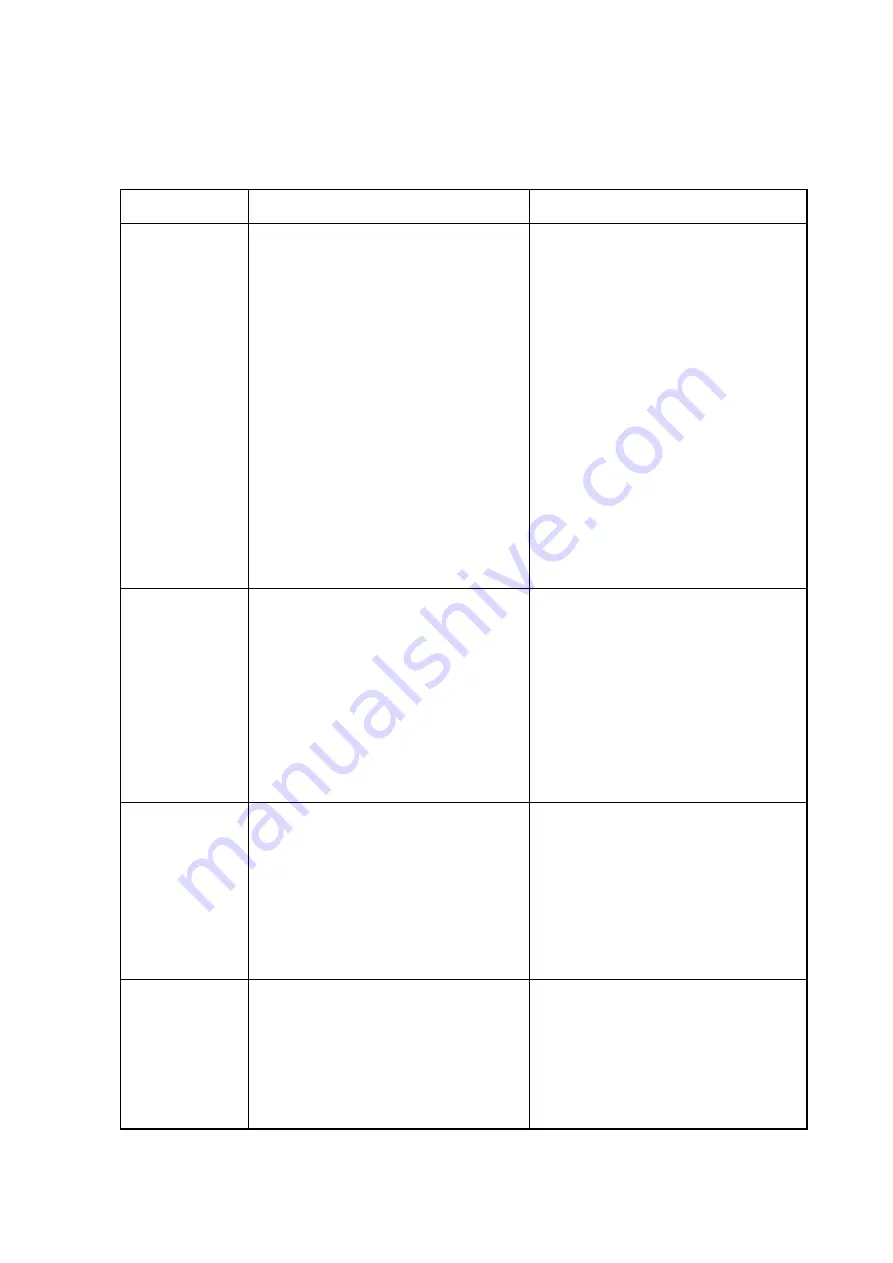

Operations

Precautions

Reasons

When starting

the engine

Immediately

after starting

Immediately

after starting

During

operation

When stopping

the engine

1) Check oil level

2) Crank the engine with starter to

check the increase in oil pres-

sure(until the needle of pressure

gauge starts to move or pressure

indicator lamp is actuated) before

starting the engine.

3) When having replaced oil, oil filter

element, or lubricating parts, or

when having stopped the engine

for extended period of time, or in a

cold place, loosen the oil pipe con-

nections and operate the starter

motor until oil is discharged. After

completing the operation, be sure

to retighten the oil pipe connections

portion before starting the engine.

1) Run the engine at idle for 5 min-

utes after starting off.

2) Check each part for leakage of

oil, gas, and air, and take proper

measure.

Check the followings:

1) Oil pressure

At idle: 0.8kg/cm

2

or more

At full load: 3.0~4.8kg/cm

2

2) If unusual sound or vibration is

heard or felt, reduce engine revo-

lutions slowly and locate the

cause.

1) Run the engine at idle for 5 min-

utes before stopping.

2) Abrupt starting of the engine

causes the engine to rotate with

oil not being distributed not only

to each part but also to the tur-

bocharger, resulting in abnormal

wear or seizure on the bearing

due to insufficient supply of oil.

3) In the case of the engine stopped

for extended time or in a cold

place, oil fluidity within the pipes

can be deteriorated.

1) Applying load abruptly If load is

abruptly applied with the engine

and turbocharger rotating

unsmoothly, such parts that a suf-

ficient amount of oil has not

reached can be seized up.

2) Leakage of oil, gas, and air (espe-

cially, oil leak) causes drop in oil

pressure and loss of oil. resulting

in seizure of the bearing.

1) Excessively low oil pressure caus-

es unusual wear or seizure of the

bearing. Too high pressure caus-

es oil leakage.

2) The engine is operated continu-

ously with unusual sound or vibra-

tion not corrected, it can be dam-

aged beyond repair.

1)

I

f the engine is put to a stop after

being operated at high load, heat

from the red-hot turbine blades is

transmitted to the bearing portion

and burns oil to cause seizure of

the bearing metal and rotating

shaft.

n