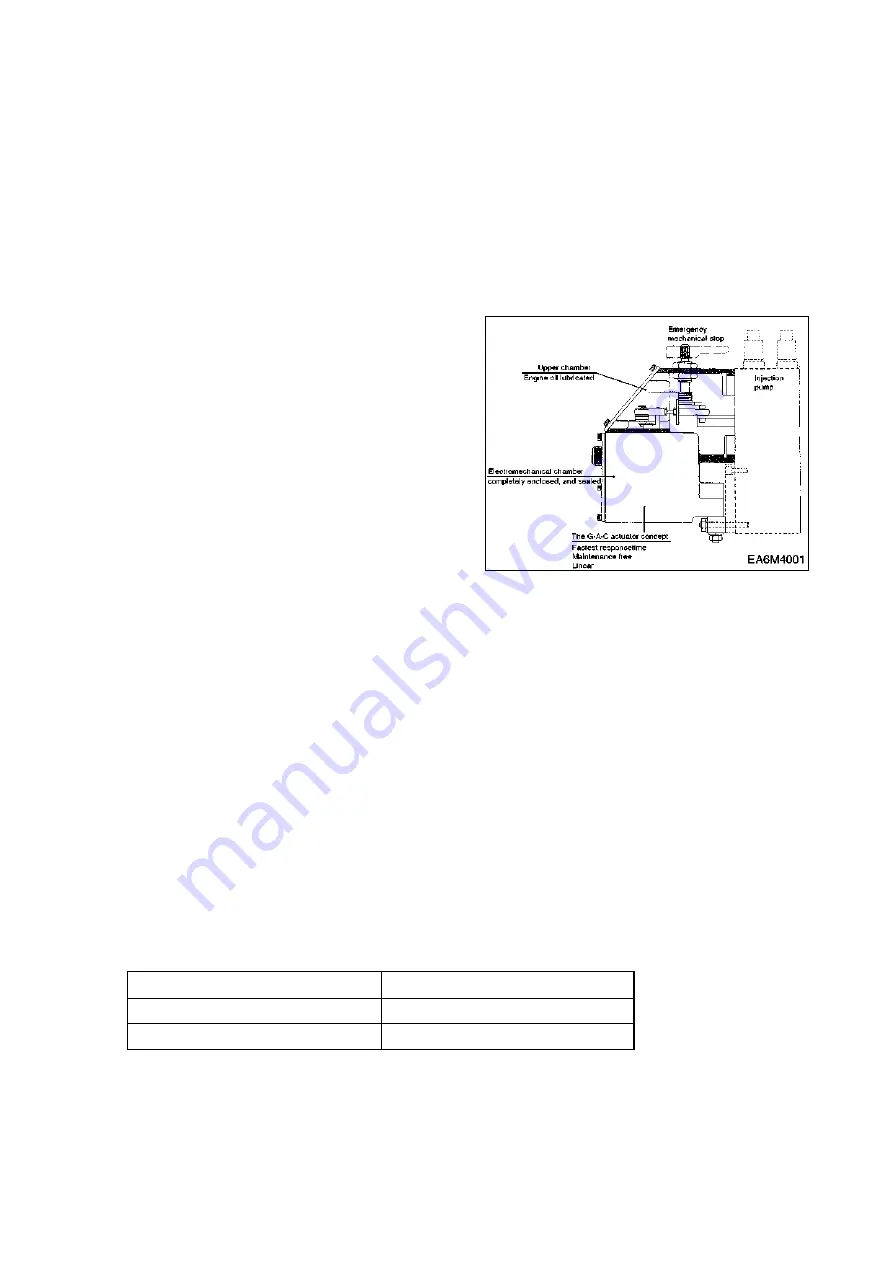

3.8.1. Injection pump

The in-line injection pump is driven via gears from the crankshaft. It is connected to the force

feed lubricating system of the engine and consequently maintenance-free. The governor

flange-mounted on the pump casing is a variable range governor designed to keep the

speed set by the speed control unit constant under conditions of varying load.

Governor system for fuel injection pump consists of “Integral Actuator” and “ Speed Control

Unit”.

1) Integral Actuator

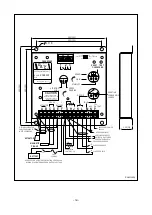

2) Speed control unit for governor system

The ESD5550 Series speed control unit is an all electronic device designed to control engine

speed with fast and precise response to transient load changes. This closed loop control, when

connected to a proportional electric actuator and supplied with a magnetic speed sensor signal,

will control a wide variety of engines in an isochronous or droop mode. It is designed for high

reliability and built ruggedly to withstand the engine environment.

Simplicity of installation and adjustment was foremost in the design. Non-interacting

performance controls allow near optimum response to be easily obtained.

The primary features of the ESD5550 Series speed control unit are the engine STARTING

FUEL and SPEED RAMPING adjustments. The use of these features will minimize engine

exhaust smoke experienced prior to attaining engine operating speed.

Other features include adjustable droop and idle operation, inputs for accessories used in multi-

engine or special applications, protection against reverse battery voltage, transient voltages,

accidental short circuit of the actuator and fail safe design in the event of loss of speed sensor

signal or battery supply.

- 17 -

Engine model

P126TI

GAC governor model

ACE 175A

Speed control unit model

ESD5550