5.5.3. Fuel system checks

Fill the tank with the recommended fuel. Keeping tanks full reduces water condensation and

helps keep fuel cool, which is important to engine performance.

Make sure fuel supply valves (if used) are open.

To insure prompt starting and even running, the fuel system must be primed with the fuel

feed pump manually before starting the engine the first time, or after a fuel filter change.

Refill at the end of each day’s operation to prevent condensation from contaminating the fuel.

Condensation formed in a partially filled tank promotes the growth of microbial organisms

that can clog fuel filters and restrict fuel flow.

If the engine is equipped with a fuel water separator, drain off any water that has

accumulated. Water in fuel can seriously affect engine performance and may cause engine

damage. DAEWOO recommends installation of a fuel water separator on generator

units.

5.5.4. Fuel Contamination and water trap

In the generator environment, the most likely fuel contaminants are water and microbial

growth (black “slime”). Generally, this type of contamination is the result of poor fuel handling

practices.

Black “slime” requires water in the fuel to form and grow, so the best prevention is to keep

water content to a minimum in storage tanks.

If diesel fuel which contains moisture is used the injection system and the cylinder liners /

pistons will be damaged. This can be prevented to same extent by filling the tank as soon as

the engine is switched off while the fuel tank is still warm (formation of condensation is

prevented). Drain moisture from storage tanks regularly. Installation of a water trap upstream

of the fuel filter is also advisable.

Notice :

A galvanized steel tank should never be used for fuel storage, because the fuel oil

reacts chemically with the zinc coating to form powdery flakes which can quickly

clog the fuel filters and damage the fuel pump and injection nozzles.

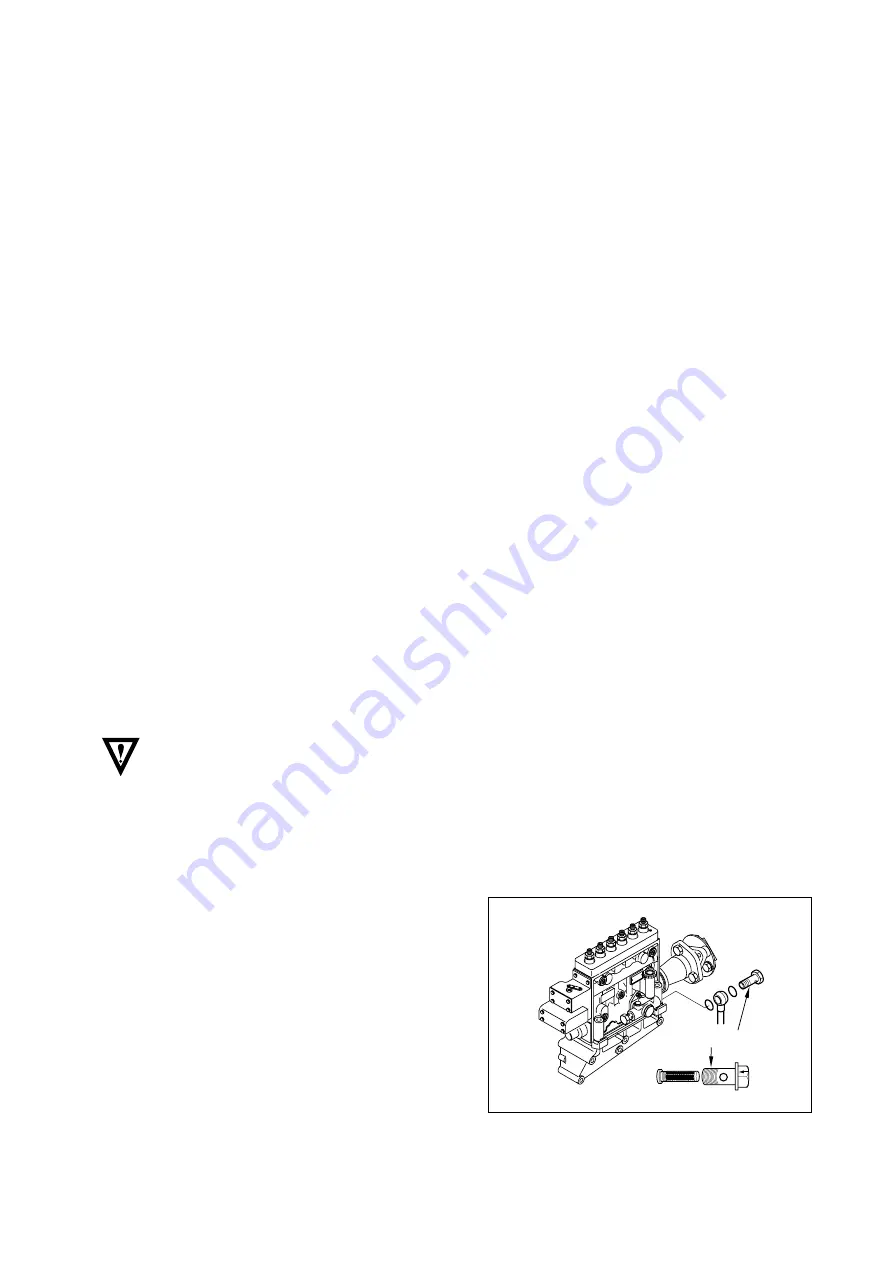

5.5.5. Priming pump strainer cleaning

Clean the priming pump strainer every 200

operation hours.

The strainer is incorporated in the priming

pump inlet side joint bolt.

Clean the strainer with the compressed air

and rinse it in the fuel oil.

- 38 -

EA7O5009

Strainer(Inner)