soak in a vessel with solvent and to clean it then with a stiff brush. In doing so, take care to

see that only the compressor wheel is immersed and that the turbocharger is supported on

the bearing casing and not on the wheel.

5.7.2. Special hints

It is recommended that the radial and axial

clearances of the rotor be checked after

every 3,000 hours operation.

This precaution will enable any wear of the

Measuring of axial clearance bearings to be

detected in good time before serious

damage is caused to the rotor and bearings.

•

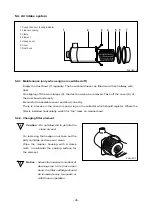

Measuring rotor axial clearance

•

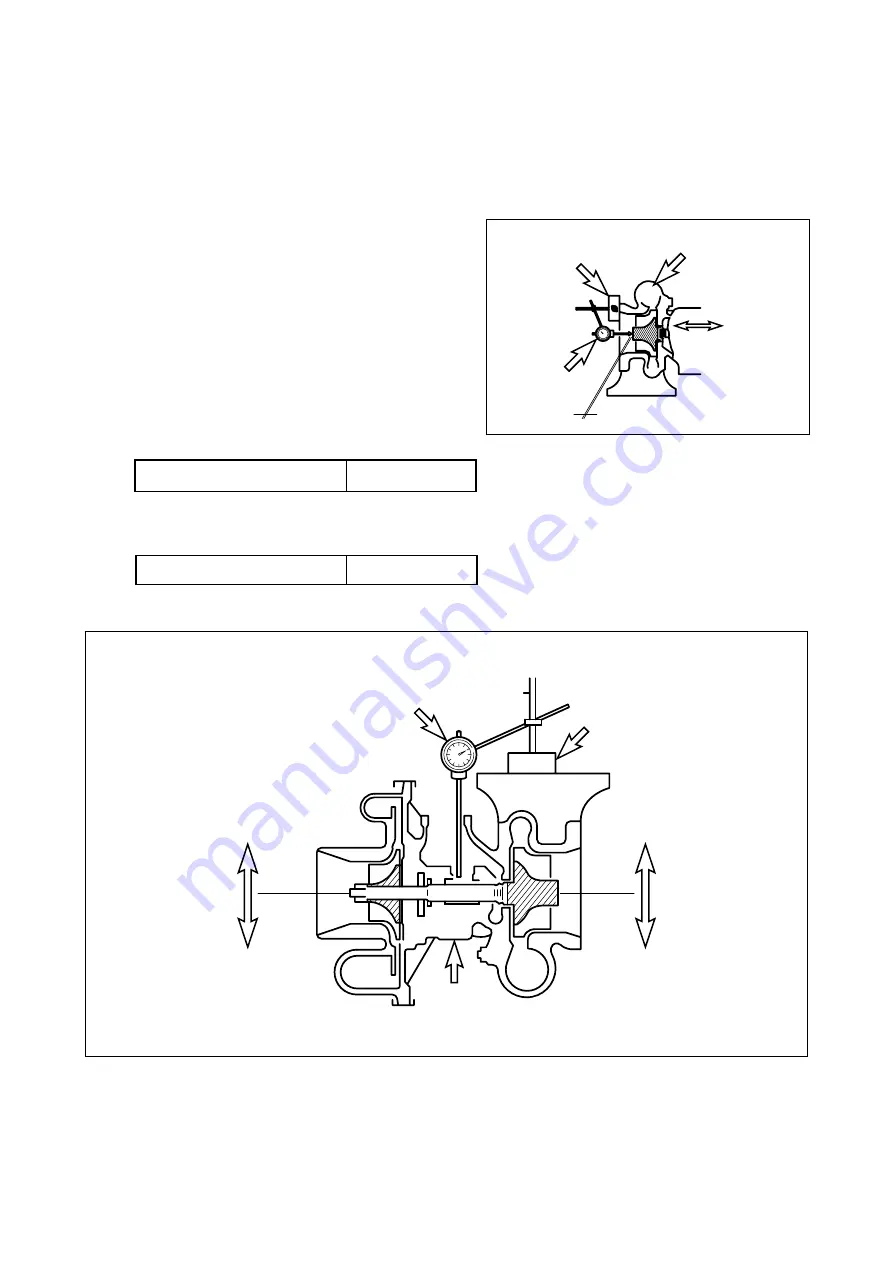

Measuring radial clearance

- 41 -

EA4M2017

Magnetic vise

Dial gauge

Turbine wheel chamber

Move the turbine

shaft to axial

direction

Wear limit : 0.20mm

EA4M2018

Dial gauge

Magnetic vise

Oil inlet

Move the turbine shaft

in both directions

simultaneously

Radial play

Limit of wear : 0.57mm

Axial clearance

0.2 mm

Radial clearance

0.65 mm

Oil

Outlet