2. Major maintenance

2.1. Preventive maintenance

The preventive maintenance means that the operator performs the servicing of engine to

obtain long life and best performance from DAEWOO diesel engine.

2.1.1. Cooling water

•

Regarding the cooling water that is to be used for engine, the soft water not the hard water

must be used.

•

The engine cooling water can be used diluting it with antifreezing solution 40% and the addi-

tive for rust prevention (DCA4) 3 ~ 5 %.

•

The density of above solution and additive must be inspected every 500 hours to maintain it

properly.

Note : The proper density control of antifreezing solution and rust preventing additive will be

able to prevent the rusting effectively and maintain the stable quality of engine.

For the improper control might give the fatal damage to the cooling water pump

and cylinder liners, detail care is needed.

•

Since DE12T and POLUS P126TI (generator diesel engine of DE12 series) cylinder liner is

dry type, particularly the cooling water control should be applied thoroughly.

•

The density of antifreezing solution and additive for rust prevention is able to be confirmed by

the cooling water test kit. (Fleetguard CC2602M)

•

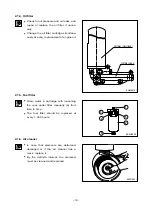

How to use the cooling water test kit

1) When the cooling water temp. of engine is in the range of 10 ~ 55 °C, loosen the plug for

cooling water discharge and fill the plastic cup about a half.

Note : In taking the cooling water sample, if the water in auxiliary tank were taken, it is hard

to measure the accurate density. Take the cooling water sample necessarily loosen-

ing the cooling water discharge plug.

2) At the state of a test paper soaked in the sampled water, after taking the paper out

through water agitation, shake off the water.

3) Wait for about 45 sec. till the color change of test paper.

Note : However, it should not elapse longer than 75 sec, and if it did, the hue would change.

- 8 -