S0703010K

Page 4

Accumulator

NOTE:

Pre-charge pressure is referred to as the "P1" pressure. The accumulator manufacturer’s

"P1" rated pressure should be stamped or marked on the accumulator’s rating plate.

Annual checks of actual pre-charge pressure should be made by tapping a hydraulic

pressure gauge (and 3-way adapter coupling) into the valve on the bottom of the

accumulator. When hydraulic fluid is pushed out the lower valve opening by the pressure

of the gas charge on the other side of the diaphragm - and there is no counter-pressure

from system oil - the valve button on the bottom of the diaphragm eventually seals off the

lower oil passage. Just after the needle on the gauge reaches its highest point (when there

is 0 bar (0 psi) resistance from hydraulic system pressure) pressure on the gauge will drop

sharply to zero, as the accumulator is completely emptied of oil and the diaphragm button

closes.

Record the highest gauge reading and compare to the "P1" rated pre-charge pressure on the

accumulator manufacturer’s data label. Repeat this test at least once a year to verify proper

functioning of the accumulator.

3.

As hydraulic system pressure overcomes accumulator pre-charge pressure, the flexible diaphragm

begins to retract upward.

4.

When system oil is at highest working pressure and the accumulator fills to maximum reserve

capacity, the flexible diaphragm is pushed up into the top of the upper chamber.

The highest working pressure is sometimes referred to as the "P3" pressure and can also be

referenced on the manufacturer’s data label on the exterior of the accumulator.

5.

If system oil pressure begins to fall off or is momentarily checked or interrupted, the energy stored on

the other side of the diaphragm, in the form of compressed gas, pushes oil back out of the lower

chamber, maintaining oil pressure of the circuit.

6.

With minimal system pressure, an equilibrium point may be reached in which accumulator pre-charge

pressure and hydraulic system oil pressure achieve a rough balance. In this condition a minimal

amount of oil is stored in the accumulator.

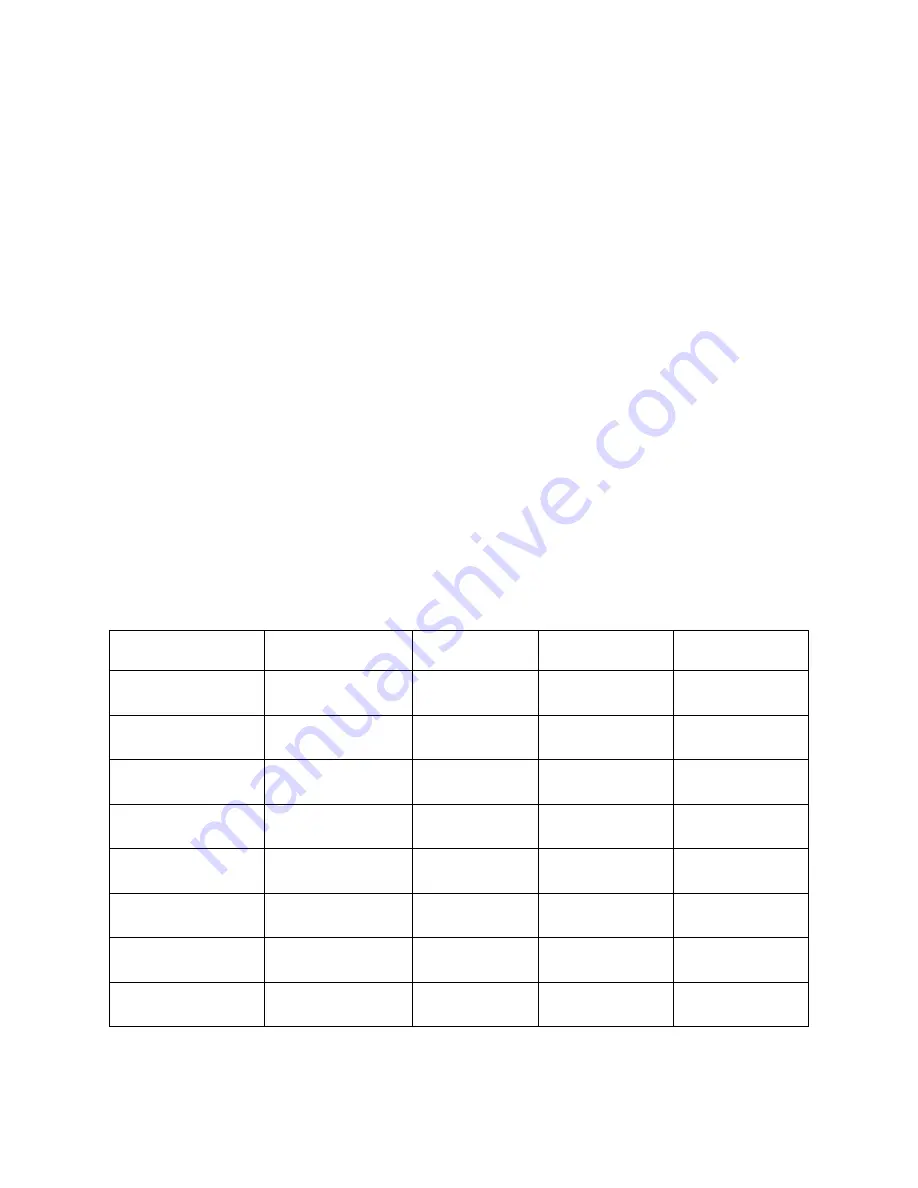

SPECIFICATIONS

Model

Serial Number

System

Charge

Pressure

Volume

Mega 200-V (Tier I

& II)

S/N 1001 and Up

Brake System

30 kg/cm²

(427 psi)

750 cc

(45.77 in

3

)

Mega 200-V (Tier I

& II)

S/N 1001 and Up

Pilot

15 kg/cm²

(213 psi)

320 cc

(19.53 in

3

)

Mega 250-V (Tier I)

S/N 1001 thru 2000

Brake System

30 kg/cm²

(427 psi)

750 cc

(45.77 in

3

)

Mega 250-V (Tier I)

S/N 1001 thru 2000

Pilot

15 kg/cm²

(213 psi)

320 cc

(19.53 in

3

)

Mega 250-V (Tier II)

S/N 2001 and Up

Brake System

30 kg/cm²

(427 psi)

750 cc

(45.77 in

3

)

Mega 250-V (Tier II)

S/N 2001 and Up

Pilot

15 kg/cm²

(213 psi)

320 cc

(19.53 in

3

)

Solar 55-V

S/N 0001 and Up

Pilot

10 kg/cm

2

(140 psi)

320 cc

(19.53 in

3

)

Solar 55-V Plus

S/N 1001 and Up

Pilot

10 kg/cm

2

(140 psi)

320 cc

(19.53 in

3

)

Summary of Contents for Solar 225LC-V

Page 2: ......

Page 4: ......

Page 7: ...1SAFETY ...

Page 8: ......

Page 46: ...S0102000 Page 38 Track Excavator Safety ...

Page 47: ...1SPECIFICATIONS ...

Page 48: ......

Page 54: ...S0205015K Page 6 Specifications for Solar 225LC V Return to Master Table of Contents ...

Page 70: ...S0205015K Page 22 Specifications for Solar 225LC V Return to Master Table of Contents ...

Page 71: ...1GENERAL MAINTENANCE ...

Page 72: ......

Page 86: ...S0302000 Page 14 General Maintenance Procedures ...

Page 99: ...1UPPER STRUCTURE ...

Page 100: ......

Page 102: ...S0402040K Page 2 Cab TABLE OF CONTENTS Removal 3 Installation 6 ...

Page 116: ...S0403050K Page 8 Counterweight Return to Master Table of Contents ...

Page 140: ...S0407000 Page 6 Swing Bearing ...

Page 165: ...1LOWER STRUCTURE AND CHASSIS ...

Page 166: ......

Page 192: ...S0505030 Page 26 Track Assembly Return to Master Table of Contents ...

Page 193: ...1ENGINE AND DRIVE TRAIN ...

Page 194: ......

Page 205: ...S0605060K Page 11 Air Conditioner Face and Defroster ARS1300L Figure 12 ...

Page 229: ...S0609000 Page 9 Drive Coupling Main Pump Figure 10 DRIVE COUPLING INSTALLATION UCHIDA PUMP ...

Page 234: ...S0609000 Page 14 Drive Coupling Main Pump ...

Page 235: ...1HYDRAULICS ...

Page 236: ......

Page 249: ...S0702170K Page 13 Hydraulic System Troubleshooting Testing and Adjustment ...

Page 272: ...S0702170K Page 36 Hydraulic System Troubleshooting Testing and Adjustment ...

Page 274: ...S0703010K Page 2 Accumulator TABLE OF CONTENTS General Description 3 Specifications 4 ...

Page 297: ...S0705000 Page 9 Cylinders ...

Page 301: ...S0705000 Page 13 Cylinders ...

Page 311: ...S0705000 Page 23 Cylinders ...

Page 315: ...S0705000 Page 27 Cylinders ...

Page 324: ...S0705000 Page 36 Cylinders 17 Force out pin bushing 1 from body of cylinder Figure 28 ...

Page 328: ...S0705000 Page 40 Cylinders ...

Page 335: ...S0707200 Page 7 Swing Motor Return to Master Table of Contents ...

Page 341: ...S0707200 Page 13 Swing Motor Return to Master Table of Contents SPECIAL TOOLS Figure 6 ...

Page 358: ...S0707200 Page 30 Swing Motor Return to Master Table of Contents ...

Page 452: ...S0708320 Page 40 Main Pump With Regulator Return to Master Table of Contents ...

Page 458: ...S0709401K Page 6 Main Control Valve Kayaba Figure 1 ...

Page 459: ...S0709401K Page 7 Main Control Valve Kayaba Figure 2 ...

Page 461: ...S0709401K Page 9 Main Control Valve Kayaba ...

Page 463: ...S0709401K Page 11 Main Control Valve Kayaba Figure 4 ...

Page 475: ...S0709401K Page 23 Main Control Valve Kayaba Figure 16 ...

Page 508: ...S0709401K Page 56 Main Control Valve Kayaba Figure 54 ...

Page 563: ...1ELECTRICAL SYSTEM ...

Page 564: ......

Page 618: ...S0802220K Page 54 Electrical System ...

Page 637: ...S0802220K Page 73 Electrical System ...

Page 649: ...1ATTACHMENTS ...

Page 650: ......

Page 670: ......