S0704090K

Page 6

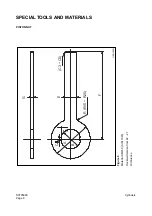

Center Joint (Swivel)

DISASSEMBLY

Refer to the assembly drawing of the swivel joint for component references (Figure 1).

1.

Clean off the exterior of the swivel joint after it has been removed.

2.

Scribe or otherwise mark a line across the cover and the body of the center joint, to allow reassembly

in the same configuration.

3.

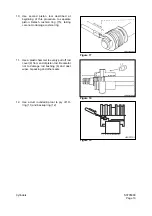

Unbolt the three 8 mm fasteners holding the cover. Use a vise or v-block to hold the assembly in

place.

4.

Remove the cover, withdraw the spindle.

5.

If the spindle doesn’t separate easily when cover and fastener bolts are removed, use a wooden

block and hammer to drive it out of the housing.

6.

O-rings and seals should be replaced whenever the assembly is being overhauled or rebuilt. For

repair procedures or emergency teardown, use a thin but rounded-tip, smooth-edge scraper or

spatula to remove O-rings or seals, to avoid causing damage to those that must be reused.

NOTE:

The O-ring (10E) shown in the assembly drawing (above the swivel joint stem lower seals)

should not be overlooked. It is tucked behind the top slip ring, doubled up inside the same

groove in the body of the Center Joint.

7.

Before reassembling the center swivel, visually inspect ball bearing surfaces for visible signs of wear,

damage or discoloration and replace any worn component.

Check clearance between the spindle and thrust plate. Replace any component that shows more

than 0.5 mm (0.020") of visible wear.

Clearance between the spindle and body of the center swivel must be tight. Replace or repair either

component if there is more than 0.1 mm (0.0039") of measurable wear.

REASSEMBLY

1.

Pre-lubricate O-rings with hydraulic oil, white grease or petroleum jelly.

2.

Thoroughly clean all other component surfaces of dirt or grease prior to reassembly.

3.

Reverse disassembly steps for reassembly.

IMPORTANT

Do not unbolt the center joint from the lower car body until an adequate number of piping block-

off plates are available, for disconnected piping lines. Be sure that system pressure has been

vented - including the hydraulic accumulator and tank reserve pressure - before disassembly is

started.

CAUTION!

Apply a very light film of white grease or petroleum jelly to the lower rim of the spindle and

inner surface of the center swivel body. Apply slow, even-handed pressure, using both

hands, to slowly push the spindle into the body. Seals may be damaged if the spindle is

pushed in too quickly.

Summary of Contents for Solar 420LC-V

Page 1: ...Return to Master Table of Contents 1HYDRAULICS...

Page 33: ...S0703010K Page 2 Accumulator TABLE OF CONTENTS General Description 3 Specifications 4...

Page 43: ...S0704090K Page 8 Center Joint Swivel...

Page 63: ...S0705000 Page 20 Cylinders Return to Master Table of Contents...

Page 70: ...S0707260 Page 7 Swing Motor...

Page 74: ...S0707260 Page 11 Swing Motor SPECIAL TOOLS Figure 5...

Page 91: ...S0707260 Page 28 Swing Motor...

Page 103: ...S0707365 Page 12 Travel Motor With Gearbox A6V160HD PARTS LIST Travel Motor Figure 12 HTS6331...

Page 107: ...S0707365 Page 16 Travel Motor With Gearbox A6V160HD Travel Motor Control HTS6331 Figure 14...

Page 136: ...S0707365 Page 45 Travel Motor With Gearbox A6V160HD 29 Remove gasket Figure 91 Figure 91 3061...