Chapter 8 Embroidery Speed (Main Shaft Speed)

BECS-328 Computerized Embroidery Machine's Manual

36

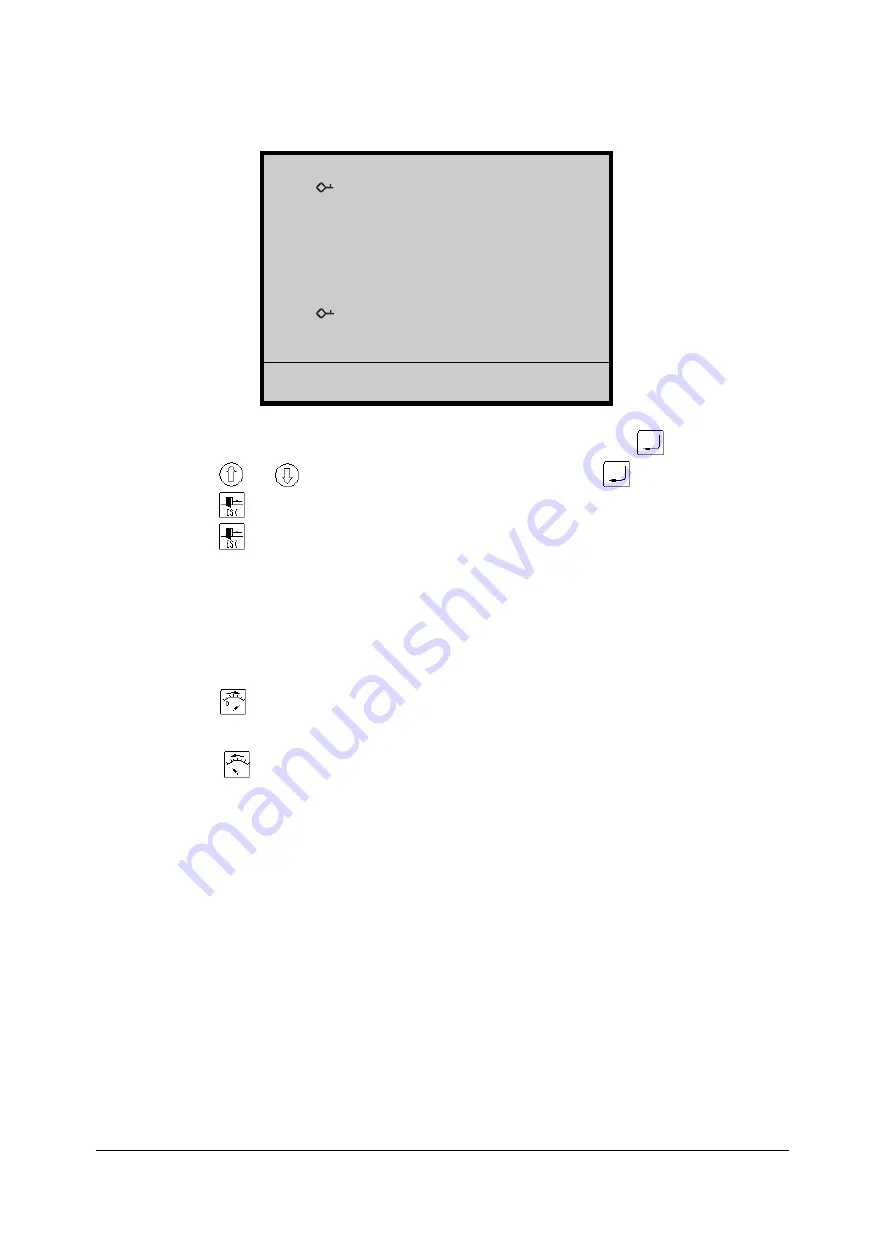

SET MACHINE PARAS

MAX. SPEED: 850

②MINIMUM SPEED: 400

③SHIFT STI. LENGTH: 5.0

④TURN OFF TRIMMING: Y

⑤TRIM MODE: 3

⑥ACTION AFTER TRIM: FRAME TO Y

⑦FRAME AFTER TRIM: N

PASSWORD:

CHECK TRIM IS OK: N

⑨SPIN ROUNDS FOR BRAKE: 1

⑩STITCHES AFTER TRIM: 2

(4)

Required by the system, input the correct password and press

“

”

.

(5)

Press "

"

、

"

" key to select the speed value, and press "

" key.

(6)

Press "

" to end the setting.

(7)

Press "

" to quit the main setting.

NOTE: The default value is recommended for the maximum speed.

8-2 Setting Embroidering Speed

It specifies the running speed during embroidering operation.

Operation:

(1)

Press "

" key. When pressing once the key, the speed will raise 10 rpm. When

having been reached the limit speed, the speed will not raise any more.

(2)

Press "

" key. When pressing once the key, the speed will reduce 10 rpm.

When reducing to 250 rpm, the speed will not reduce any more.