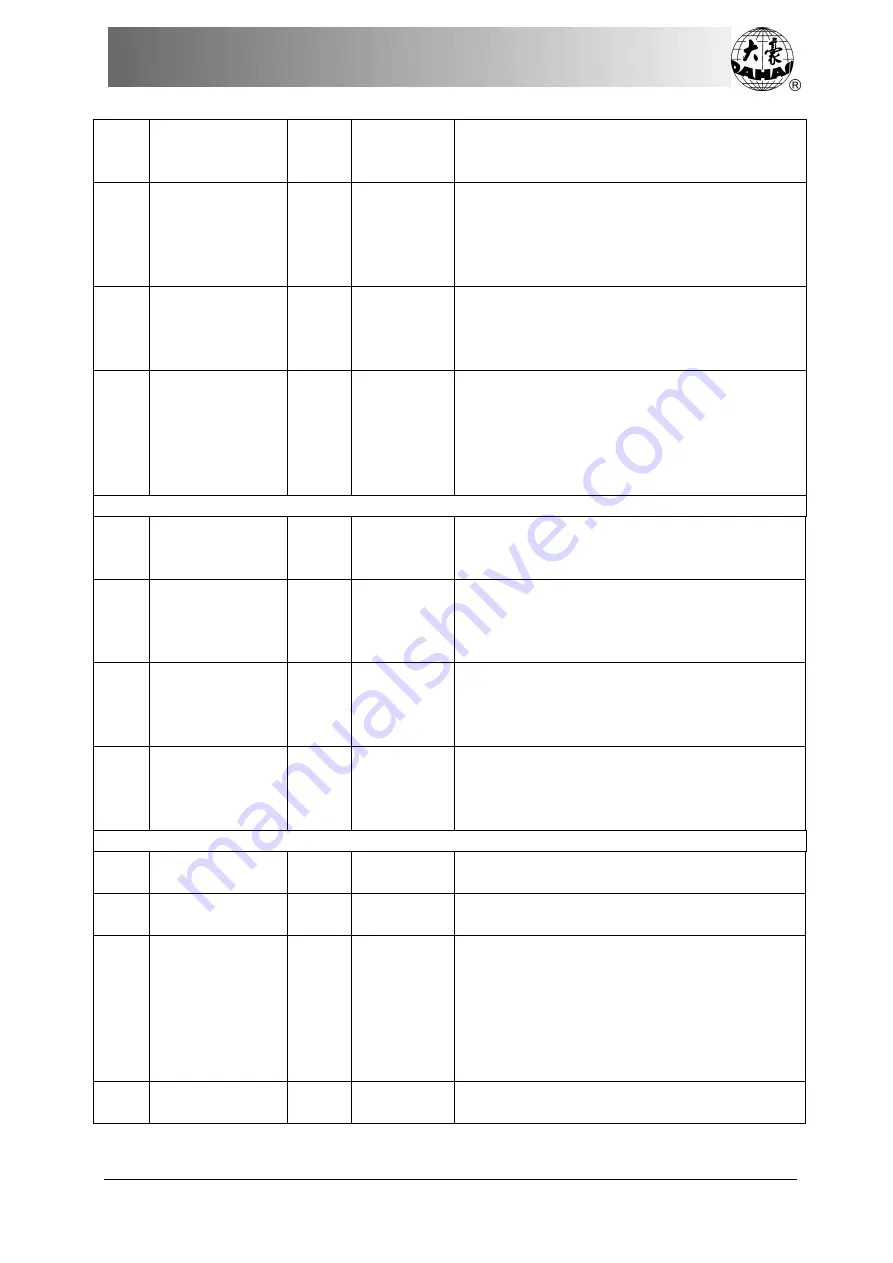

Appendix 4 Loop Embroidery Parameter List

BECS-D19 User’s Manual

155

Number

patching to the set stitch before thread

breakage, all heads will start embroidery, in

order to ensure product quality.

F09

Back to

Threading

Position at

Thread

Breakage

Yes

No, Yes

Threading position is set for re-threading. This

parameter is to quickly complete threading

by pointing threading point of shuttle to that

of the needle.

F15

Stitch Number

before Thread

Breakage

Detection

3

0~15

stitches

This parameter is to set the stitch number

before the thread breakage detection is

activated after embroidery start.

F41

Thread

Breakage

Detection Mode

U

Upper head

board (U),

lower head

boar

(L),

EF196,

Ef102

Set thread breakage detection mode.

Frame Related Parameters

F14

Over Frame at

Start

No

No, pull

bar, all,

after

Adjust loop embroidery stitch and flat

embroidery stitch.

F23

Chained

Embroidery

Frame-moving

Angle

6

0~10

Adjust action order, which will influence

product quality.

F80

Looping

Embroidery

Frame-moving

Angle

6

0~10

Adjust this parameter to improve looping

quality.

F47

Loop

Embroidery

Frame-moving

Curve

0

0

、

1

、

2

Select loop embroidery frame-moving curve.

Main Shaft Related Parameters

F17

Slow Stitiches at

Start

3

1~9 stitches

Set the slow stitches at embroidery start by

“main shaft slow speed”.

F18

Max. Rotation

Speed

650

rpm

500~650

rpm

Set the maximum rotation speed of

embroidery, by increment of 50 rpm.

F19

Stop

Compensation

0

0~30

When set as 0, it is the earliest stop position,

and to adjust this parameter is to adjust the

stop position of main shaft so as to solve the

problem of not stop in position due to

mechanical inertia. The larger the value, the

more backwards the stop angle moves. Setting

range: 0~6.

F20

Rotation Speed

Compensation

0%

-15%~15%

Adjust this parameter by software can make

actual rotation speed comply with set rotation