M

ATERIALS

FOR

S

ETTING

W

ELDING

JOB

R

EFERENCE

M

ATERIALS

C

HAPTER

10

160

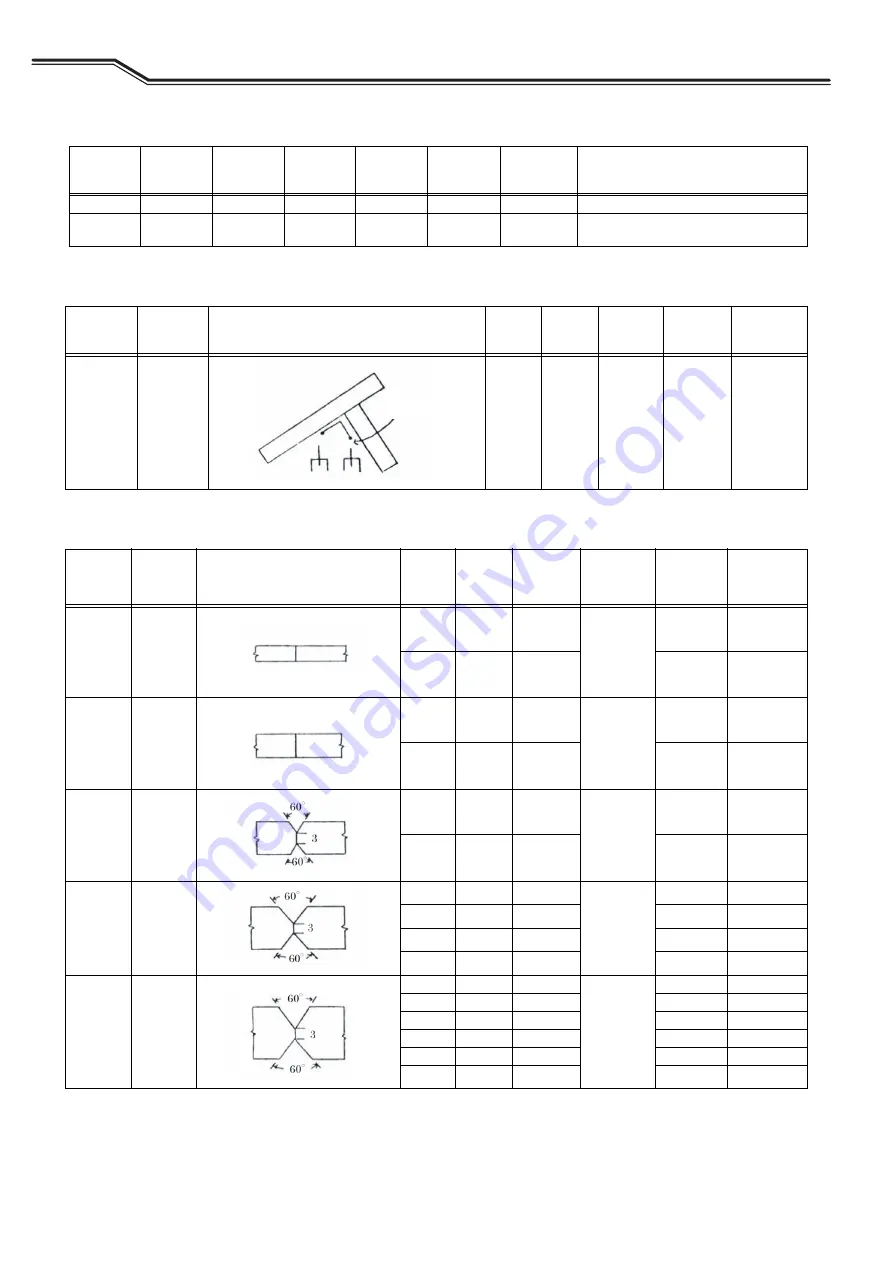

Example for welding JOB of downward welding

Example for welding JOB of upward welding

Example for both side welding JOB of downward butt welding (Manual mode)

Plate

thickness

t (mm)

Wire

diameter

(mm

Φ

)

Shape of

joint weld

Current

(A)

Voltage

(V)

Manual/

Auto.

(cm/min)

Wire

consumption

(g/min)

Remarks

2.3

1.2

Butt

100

22 to 23

70

6.2

Check back bead appearance

3.2

1.2

Fillet

100

21 to 22

70

6.2

Leg length: 4 - 5mm, Throat depth: 2.5mm

Leg length: 10 mm

Plate

thickness

t (mm)

Wire

diameter

(mm

Φ

)

Shape of joint weld

Current

(A)

Voltage

(V)

Manual/

Auto.

(cm/min)

Gas flow

rate

(L/min)

Remarks

12

1.2

100 to

110

20 to 21

30

15 to 20

Weaving

Leg length:

10 mm

Plate

thickness

t (mm)

Wire

diameter

(mm

Φ

)

Bevel shape

Number

of layers

Current

(A)

Voltage

(V)

Gas flow

rate (L/min)

Manual/

Auto.

(cm/min)

Wire

consumption

(g/min)

6.0

1.2

1

170

25 to 26

15 to 20

30

2.7

2

180

26 to 27

30

2.7

9.0

1.2

1

270

29 to 30

15 to 20

30

2.7

2

290

30 to 31

30

2.7

12.0

1.2

1

280

30 to 31

15 to 20

40

3.6

2

330

33 to 34

40

3.6

19.0

1.2

1

300

31 to 32

15 to 20

45

4.0

2

300

31 to 32

45

4.0

1

340

32 to 33

45

4.0

2

280

30 to 31

45

4.0

25.0

1.2

1

300

31 to 32

15 to 20

45

4.0

2

320

32 to 33

45

4.0

3

320

32 to 33

45

4.0

1

340

32 to 33

45

4.0

2

320

32 to 33

45

4.0

3

320

32 to 33

45

4.0

Stop at both ends