S

ETTING

I

NTERNAL

F

UNCTIONS

W

ELDING

C

ONDITION

C

HAPTER

6

93

Chapter 6

W

elding Condition

–

Each pressing the UNIT CHANGE key, the wire feed speed display and the welding current display switches

alternatively. Switch to the welding current display, and set the welding current in the unit of 1 A.

–

Switching to the welding current display can check the wire feed speed automatically set.

–

In using the welding power source in the automatic machine mode, refer to the graph in " 6.7.2.4

external command voltage". (When the internal function F4 (Auto/Semi-auto mode) is used with the setting of

Automatic machine 1 mode)

6.7.2.21 F25 to F28: External output terminal setting

•

Through F25, you can set the functions of OUT-EXT1 ("3" – "4") on the terminal block for external connection.

•

Through F26, you can set the functions of OUT-EXT2 ("5" – "6") on the terminal block for external connection.

•

Through F27, you can set the functions of OUT-EXT3 ("7" – "8") on the terminal block for external connection.

•

Through F28, you can set the functions of OUT-EXT4 ("9" – "10") on the terminal block for external connection.

Configurable functions are as shown in the below table.

6.7.2.22 F29 to F32: External input terminal setting

Set the function of external input terminals. (when using robot or automatic machines)

•

F29: set the function of IN-EXT1 ("5" to "9") on the external connection terminal block TM3.

•

F30: set the function of IN-EXT2 ("6" to "9") on the external connection terminal block TM3.

•

F31: set the function of IN-EXT3 ("7" to "9") on the external connection terminal block TM3.

•

F32: set the function of IN-EXT4 ("8" to "9") on the external connection terminal block TM3.

For the details of external connection terminal block; (

Connection of automatic machine)

The functions allocable to F29 to F32 are as follows:

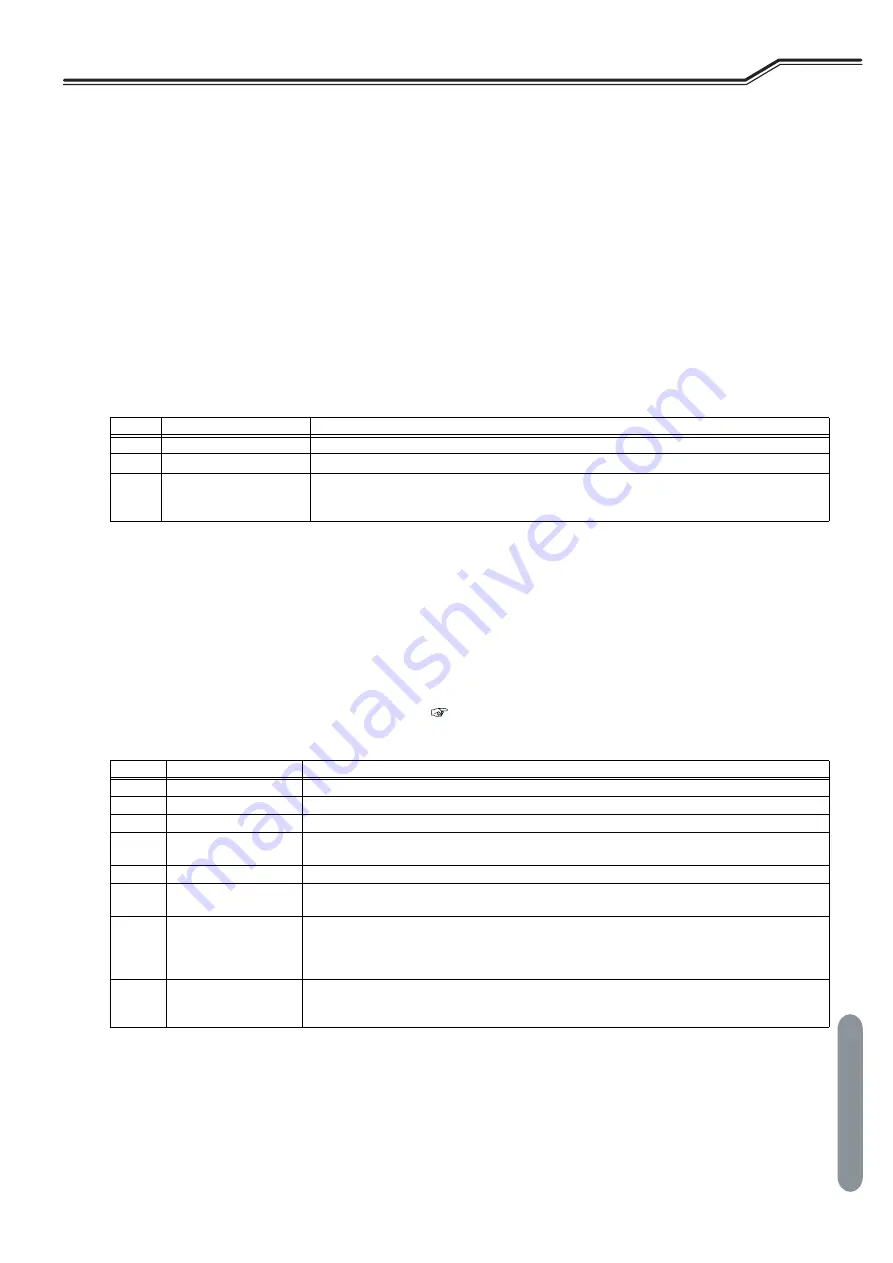

Setting Function

name

Explanation

0

−

No function is allocated.

1

〜

3

−

No function is allocated in this machine.

4

Alarm Signal of Welding

Monitor

A welding condition error is detected during welding, and the signal is output to the external terminal.

If either of the current/voltage is out of the preset range, the external output terminal with this function

is closed.

Setting Function

name

Explanation

0

-

No function is allocated.

1

Gas valve

Causing short circuit between terminals opens the gas valve. (*1)

2

Inching

Causing short circuit between terminals starts inching.

3

Retract

When inching operation is performed after short circuit is caused between terminals are short-circuited,

the wire feeding motor reverses to retract the wire. (*2)

4

Start

Causing short circuit between terminals starts welding. (torch switch: ON) (*3)

5

Loading welding

condition

The welding JOB stored on the memory can be read out by combination of signals. (*4), (*5)

6

DC/PULSE switch

Short-circuit between terminals allows DC welding mode.

Open-circuit between terminals allows DC pulse welding mode. Selecting optional "DC Wave Pulse"

beforehand allows DC wave pulse welding mode. (*6), (*7)

7

WAVE PULSE/

PULSE switch

If "DC Pulse" or "DC Wave Pulse" has been selected, short-circuit between terminals allows DC wave

pulse welding mode.

Open-circuit between terminals allows DC pulse welding mode. (*6), (*7)

*1: When the gas valve is opened by the signal from the external input terminal, the gas valve will not close when welding

completes or according to the timer (2 minutes). In order to stop gas, ensure to open the terminals.

*2: Causing short circuit between the external input terminals before turning on the inching signal. To stop the operation, turn off

the inching signal and then disconnect the external input terminals.

*3: The starting terminal of the feeder receptacle on the front of welding power source becomes deactivated.

*4: Combination of the external input terminals enables to read out the welding JOB of the JOB No. 1 to 16 (Registration No. 1 to

16) registered on the memory. The corresponding JOB No. are as shown in the below table.