G

ROUNDING

AND

C

ONNECTION

OF

I

NPUT

P

OWER

S

UPPLY

C

ONNECTION

C

HAPTER

4

40

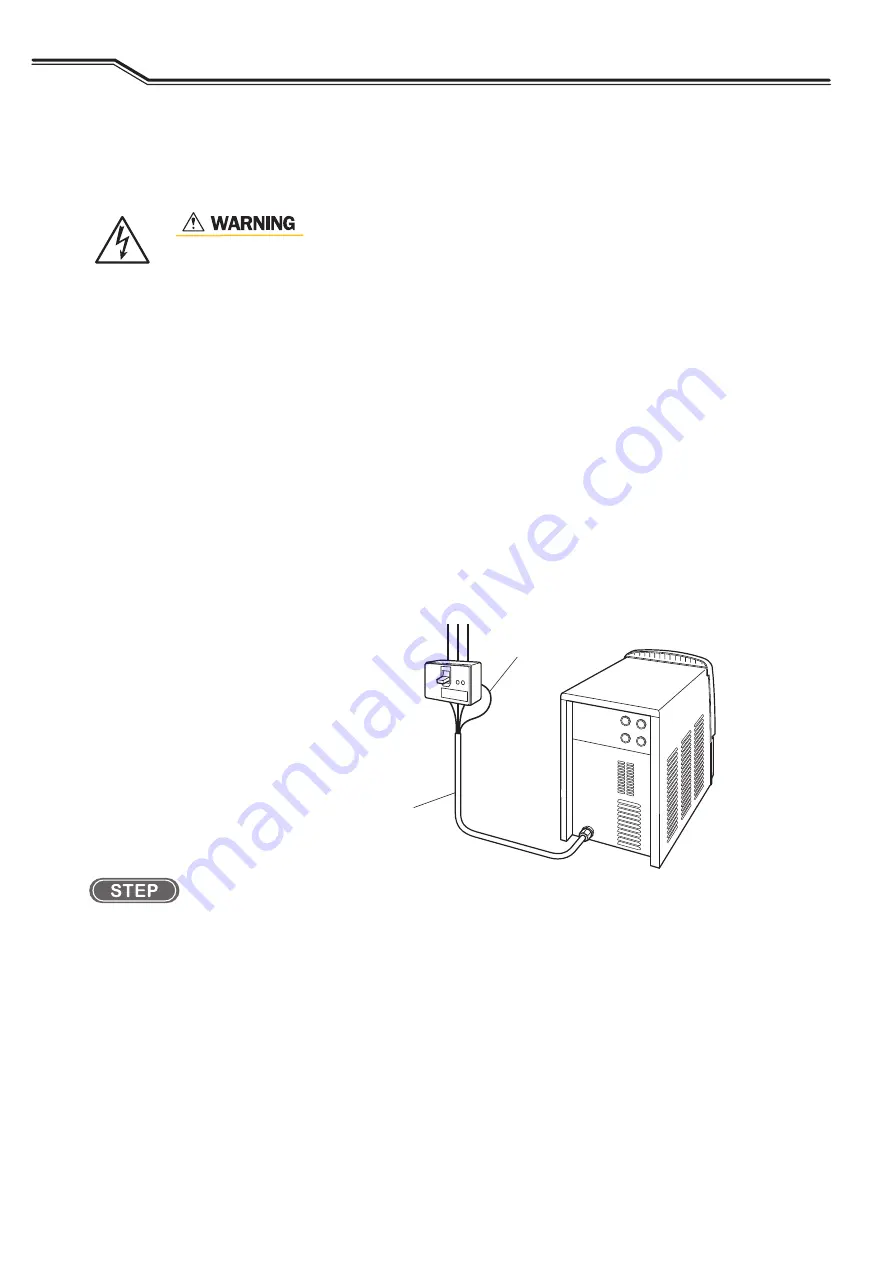

4.3 Grounding and Connection of Input Power Supply

This section explains the procedure for performing grounding work, connecting the welding power source and input

power supply (power supply at facility side).

1.

Check that input power is turned off with the disconnect switch connected to the welding power source.

2.

Perform grounding work for welding power source.

●

Grounding cable: AWG10 (5.3 mm

2

) with 10 mm

Φ

terminal × 1

The grounding cable is a striped pattern in yellow and green.

3.

Connect the power cables (3 pcs) to the output terminals of power source at facility side.

●

Input cable: AWG10 (5.3 mm

2

) with 10 mm

Φ

terminal × 3

Grounding and connection of input power supply is complete. Procedure is followed by 4.4

•

When the welding power source is used in a humid environment such as construction

site, or location with highly conducting material such as steel plate or on steel structure,

install a leakage breaker.

Otherwise, electric shock due to leakage of electricity may occur.

•

Be sure to install a switch with fuse or a circuit breaker to the input side of each welding

power source.

Otherwise, electric shock and fire due to overcurrent or damage to the welding power

source may occur.

•

If the welding power source which is not grounded is used, voltage will be generated in

the case through the capacitor between the welding power source input circuit and the

case or floating capacity (electrostatic capacity naturally generated between the input

conductor and the case metal). If you touch the case, you may suffer from electric

shock. Be sure to ground the case of the welding power source.

•

Be sure to connect the input cable (3 pcs) in the correct position and securely tighten

them to the terminal block.

Improper connection may cause electric shock, fire and damage to the welding power

source.

Mount a switch with fuse or a circuit

breaker on each welding power source.

Green/Yellow cable for

grounding cable

Input cable