9-3

Chapter 9

T

roubleshooting

A

CTION

IN

C

ASE

OF

E

RROR

T

ROUBLESHOOTING

C

HAPTER

9

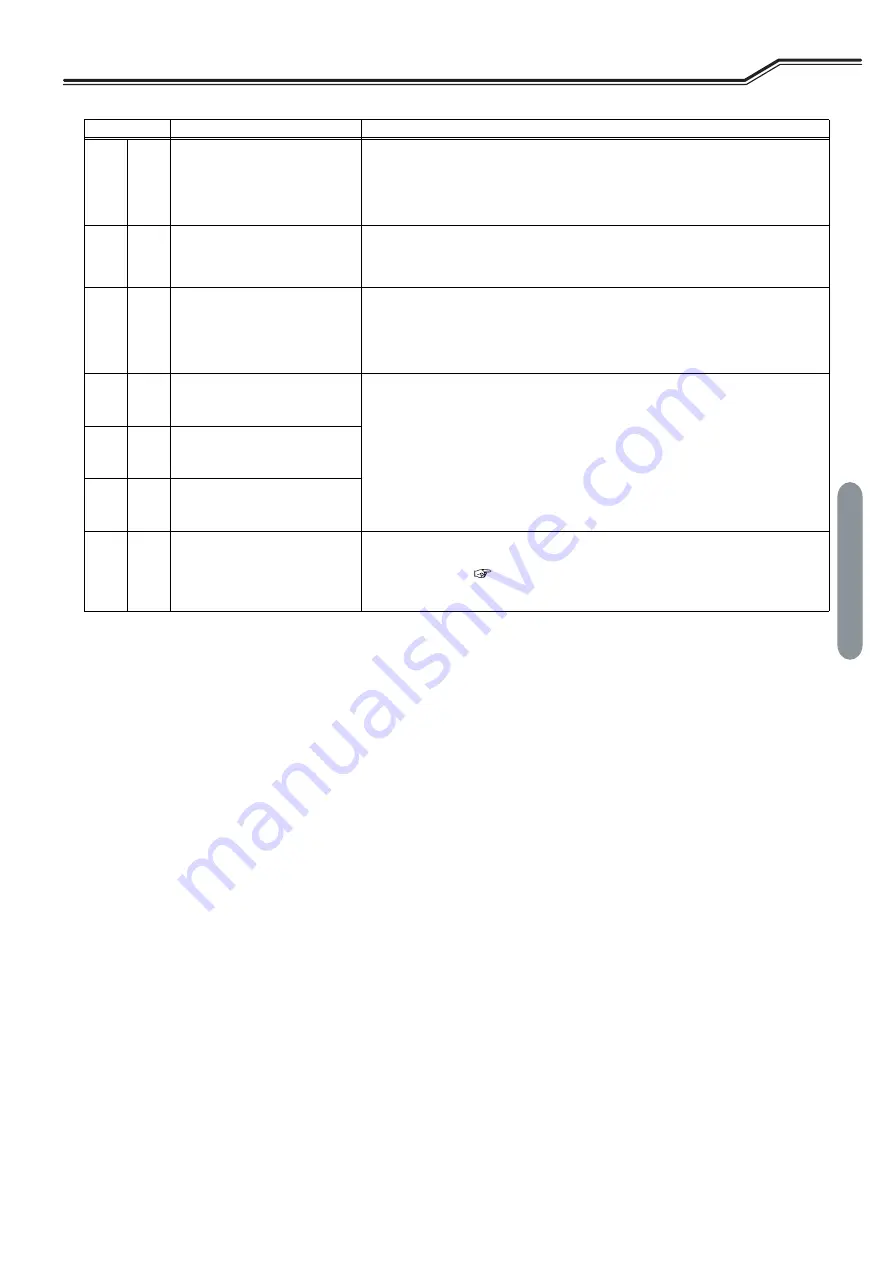

E-

700 An over current was detected at

the output side of the welding

power source (*1)

• Check that the chip at the end of torch is not contacting the base metal.

• Check that the power cables such as cables for base metal side and torch

side are not short-circuited.

• The error code will disappear when the power switch is turned off.

E-

710 The phase W of input voltage for

primary side is not connected

(*1)

• Check that there is no problem in input voltage for primary side and in cable

wiring.

• The error code will disappear when the power switch is turned off.

E-

800

801

The rotation rate of the motor of

wire feeder was not detected

(*1)

• Check that there is no disconnection, short-circuit or other abnormalities in

the cables connecting the wire feeder.

• Check that there is no problem in the wire feeder.

• The error code will disappear when the power switch is turned off.

E-

810 The temperature of the governor

circuit

-

exceeded the allowable

range (*1)

• Check that the wires are not stuck or there are no other abnormalities in the

welding torch or wire feeder.

• The error code will disappear when the power switch is turned off.

• The "E-820" indication will disappear when any key of the operation panel is

pressed.

E-

820 The current in the wire feeder

motor exceeded the warning

level (*2)

E-

830 The current in the wire feeder

motor exceeded the WARNING

detection level (*1)

E-

951 There is a duplicate ID on a

single bus (*1)

• Turn off the power switches of all other CAN-connected welding power

sources, then turn on the power switches and check the setting of internal

function F43. (

-

• The error code will disappear when the power switch is turned off.

Error

-

code

Error cause

Action and how to cancel error