Important Note

Service Form SF99006 and an isometric sketch of the Remote Piping Layout showing pipe size, location of fittings, measured lengths, and

elevations MUST BE SUBMITTED TO Daikin McQuay Technical Response Center and reviewed at least two weeks prior to beginning piping

installation. McQuay Factory Service will not perform startup without reviewed Service Form SF99006 and drawing. Installation must match

reviewed drawing.

All field piping, wiring and procedures must comply with design guidelines set forth in the Remote Evaporator section of product literature, and be

performed in accordance with ASHRAE, EPA, local codes and industry standards. Any product failure caused or contributed to by failure to comply

with appropriate design guidelines will not be covered by manufacturer's warranty. Daikin McQuay Technical Response: Fax: 763-509-7666

Phone : 540-248-9201; E-mail: techresponse@mcquay.com

116

IM 1167

Remote Evaporators

Remote Evaporator Refrigerant Piping

Careful design of refrigerant piping is necessary for proper

system operation. Design the refrigerant piping to accomplish

the following:

1

Assure proper refrigerant feed to the evaporator.

2

Provide practical and economical refrigerant line sizes

without excess pressure drop.

3

Maintain uniform oil return to the compressor under all

load conditions.

4

Refer to the latest version of the ASHRAE Handbook for

recommended piping practice; use included tables for

correct pipe sizing.

5

Keep the refrigerant suction line pressure drop to a

maximum of 2 F. in saturated temperature equivalent.

6

Each suction line's velocity must be sufficient to carry oil

considering a 25% capacity reduction in each circuit.

7

When facing the unit control box, the left-hand

compressor is circuit # 1, and the right-hand is circuit #

2. If present, the compressor behind #2, on the right-hand

side, is circuit #3.

8

Liquid lines may be insulated to prevent collection of

condensation, if needed.

The following applies to all size units:

•

Maximum linear line length cannot exceed 75 feet

•

Maximum total equivalent length (TEL) cannot exceed 180

feet (75 feet for vertical suction lines)

•

The evaporator cannot be located more than 20 feet above or

30 feet below the outdoor unit.

•

Suction line connection at unit = 4 1/8-inch OD each

•

Underground refrigerant piping is not permitted

•

Field piping must include adequate service taps for checking

filter-drier, subcooling, and superheat.

•

Insulate complete suction lines. Liquid lines may be

insulated to prevent collection of condensation if required.

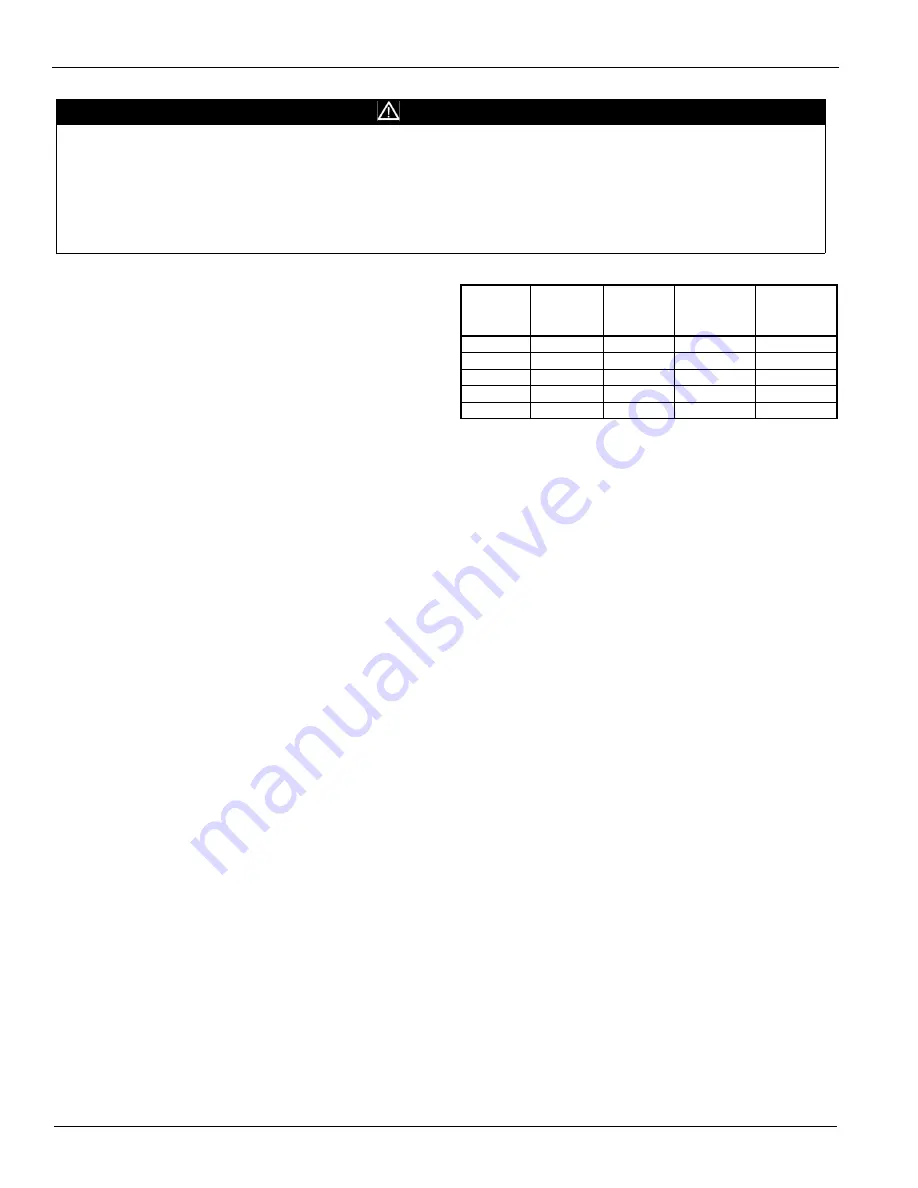

Table 94: Fitting Equivalent Feet of Pipe

Line Size

In. OD

Angle Valve

Globe

Valve

90-Degree

Std. Radius

Elbow

90-Degree

Long Radius

Elbow

2 5/8

29.00

69.0

6.0

4.1

3 1/8

35.0

84.0

7.5

5.0

3 5/8

41.0

100.0

9.0

5.9

4 1/8

47.0

120.0

10.0

6.7

5 1/8

58

140

13

8.2

Note: TEL values for the filter-drier and solenoid valve are already included

and should not be added to the liquid line drop.

Piping Layout

Figure 55

shows the piping layout for one of the two or three

refrigerant circuits for AWS units with a remote evaporator.

The outdoor unit, the evaporator, and a kit of refrigerant

components are shipped as separate pieces for field mounting,

wiring, and piping. The suction shutoff valve is standard on

remote evaporator units. Note: Field insulation of the suction

lines and the liquid line on circuits with economizers is

required. The outdoor unit will have a refrigerant charge equal

to that of a packaged unit pumped down into the condenser.

The additional charge of refrigerant and oil required by the

field piping is supplied and installed by the customer. The

location and size of the refrigerant connections are shown on

the dimension drawings beginning on

page 126

.