36

IM 1167

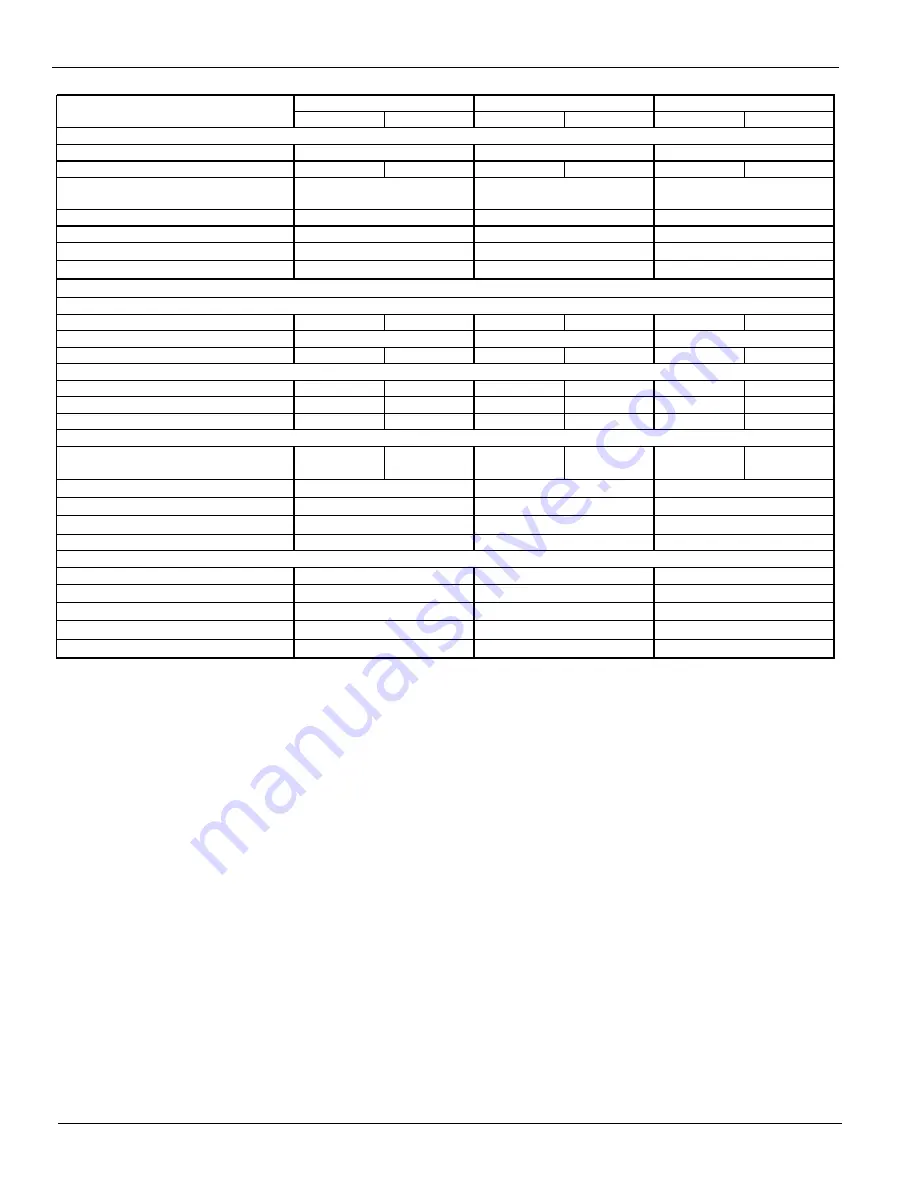

Physical Data (VFD)

Table 31: Physical Data (60 Hz, Premium Efficiency, VFD models)

CIRCUIT 1

CIRCUIT 2

CIRCUIT 1

CIRCUIT 2

CIRCUIT 1

CIRCUIT 2

Unit Cap. @ AHRI tons (kW)

Unit Operating Charge lbs (kg)

200 (91)

200 (91)

225 (102)

225 (102)

(235) (107)

(235) (107)

Unit Dimensions

L x W x H, in. (mm)

Unit Operating Weight, lbs. (kg)

Unit Shipping Weight, lbs (kg)

Weight-Add for Copper Fins

Weight-Add for Louvered Panels

Nominal Capacity, tons (kW)

105 (369)

105 (369)

105 (369)

125 (439)

125 (439)

125 (439)

Minimum Capacity (% of Full Load)

Oil charge per circuit , gallons (liters)

4.5 (17)

4.5 (17)

4.5 (17)

5.5 (21)

5.5 (21)

5.5 (21)

Pumpdow n Capacity, lbs (kg)

333 (151)

333 (151)

375 (170)

375 (170)

375 (170)

375 (170)

Coil Inlet Face Area, sq. ft. (sq. m.)

196.9 (18.3)

196.9 (18.3)

221.5 (20.6)

221.5 (20.6)

221.5 (20.6)

221.5 (20.6)

Row s Deep/Fins Per Inch

3 / 16

3 / 16

3 / 16

3 / 16

3 / 16

3 / 16

Number of Fans per Circuit

Fan Diameter: 31.5 in. (800 mm)

Fan Motor, hp (kW)

Fan & Motor RPM

Fan Tip Speed, fpm (m/s)

Airflow , cfm (l/s)

Shell Dia.-Tube Length, in.(mm)

Water Volume, gallons (liters)

Victaulic inlet/outlet conn. in. (mm)

Max. Water Pressure, psi (kPa)

Max. Refrigerant Press., psi (kPa)

325 (2241)

325 (2241)

152 (1048)

158 (599)

158 (599)

8 (2199

8 (219)

10 (273)

EVAPORATOR, DIRECT EXPANSION SHELL AND TUBE

20 x 154 / (508 x 3900)

20 x 154 / (508 x 3900)

26 x 154 / (660 x 3900)

CONDENSER FANS, DIRECT DRIVE PROPELLER TYPE

9

20

20

20

CONDENSERS, HIGH EFFICIENCY FIN AND TUBE TYPE

1124 (510)

1124 (510)

17183 (7794)

18389 (8341)

2372 (1076)

2679 (1215)

2679 (1215)

AWS240BDP VFD

8602 x 2225 x 2548

9504 x 2225 x 2545

9504 x 2225 x 2545

232.7 (818)

256.3 (901)

277.6 (976)

AWS265BDP VFD

AWS290BDP VFD

18435 (8362)

19641 (8909)

21512 (9758)

374 x 88 x 100

19859 (9008)

8

8

9

9

COMPRESSORS, SCREW, SEMI-HERMETIC

1012 (459)

Data

BASIC DATA

339 x 88 x 100

374 x 88 x 100

9

1.4 (1.05)

1.4 (1.05)

1.4 (1.05)

6984 (35)

6984 (35)

6984 (35)

850

850

850

152 (1048)

152 (1048)

325 (2241)

177360 (83704)

199530 (94167)

199530 (94167)

276 (1043)

Note: A 20 mesh strainer must be placed in the supply water line just prior to the inlet of the evaporator.

Care must be exercised when welding pipe or flanges to the evaporator to prevent any slag from entering the vessel.

This information applies only to Rev 0B models of AWS-B. For Rev 00 models, consult CAT 600-6; Rev 0A, CAT 600-7.