Si002155E

Partition Plate / Sound Insulations

Removal Procedure

19

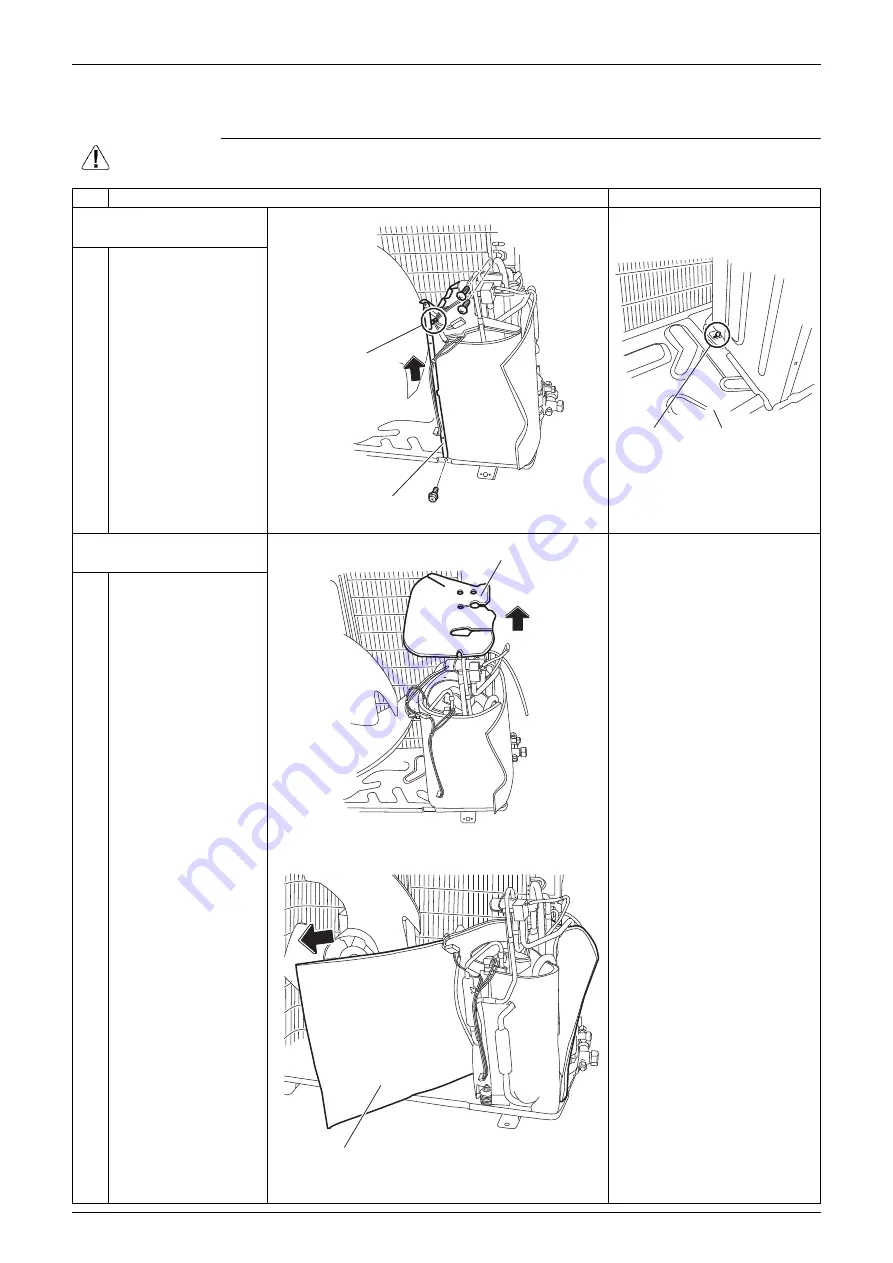

5. Partition Plate / Sound Insulations

Warning

Be sure to wait for 10 minutes or more after turning off all power supplies before

disassembling work.

Step

Procedure

Points

1. Remove the partition

plate.

When reassembling, fit the

hook into the bottom frame.

1

2

Detach the snap band

of compressor harness.

Remove the 3 screws,

and then the partition

plate.

2. Remove the sound

insulations.

Since the piping ports are

torn easily, remove the

sound insulation carefully.

1

Remove the sound

insulation (top).

2

Remove the sound

insulation (outer).

(R26211)

Snap band

Partition plate

(R26212)

Hook

Bottom frame

(R26213)

Sound insulation (top)

Sound insulation (outer)

(R26214)