Si12-994

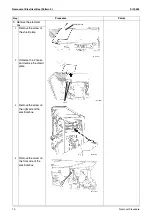

Removal Procedure

1

Table of Contents

1. Removal of Outer Panels ........................................................................2

2. Removal of Electrical Box (Pattern 1) .....................................................3

3. Removal of Electrical Box (Pattern 2) .....................................................7

4. Removal of PCBs (Pattern 1)................................................................12

5. Removal of PCBs (Pattern 2)................................................................16

6. Removal of Fan Motor...........................................................................19

7. Removal of Sound Blankets..................................................................20

8. Removal of Coils / Thermistors .............................................................22

9. Removal of Four Way Valve / Defrost Solenoid Valve ..........................24

10.Removal of Distributor...........................................................................26

11.Removal of Compressor .......................................................................27

Note:

The illustrations may be slightly different depending on the model.