7

Inspection and maintenance

Installation and maintenance instructions

37

Daikin Altherma EHS(X/H)(B)-D

Heat pump (indoor unit) with integrated heat accumulator

008.1444099_01 – 11/2018 – EN

WARNING

Temperatures of up to 90 °C can occur during operation

under the protective cover of the indoor unit. During opera-

tion, hot water temperatures of > 60 °C occur.

▪ Touching components during or after operation leads to

a risk of burns.

▪ Water discharged during maintenance and repair work

can cause scalding on contact with the skin.

▪ Before carrying out maintenance and inspection work,

allow the indoor unit to cool down sufficiently.

▪ Wear protective gloves.

WARNING

Touching live parts can result in an electric shock and lead

to potentially fatal injuries and burns.

▪ Before beginning work on live parts, disconnect all cir-

cuits of the system from the power supply (switch off ex-

ternal main switch, disconnect fuse) and secure against

unintentional restart.

▪ The electrical connection and work on the electrical

components should only be performed by electrical en-

gineers in compliance with valid standards and

guidelines as well as the specifications of the energy

supply company.

▪ Device covers and service panels must be replaced as

soon as the work is complete

1

Removing the cover and thermal insulation (see

Chap. 4.4.2

).

2

Check the function of the indoor unit and all installed accessory

components (backup heater, solar system) by checking the tem-

perature display and switching states in the individual operating

modes.

3

If a solar system of the DrainBack type is connected and in oper-

ation, shut it off and empty the collectors.

4

If the indoor unit is operated in a bivalent, alternative system,

switch off all heat generators and deactivate the bi-valence con-

troller.

5

Visual check of the general condition of the indoor unit.

6

Visual check of the water storage tank level (filling level indic-

ator).

▪ If necessary, replenish water (

Chap. 7.2.1

), determine and rem-

edy the reason for the low water level.

7

Check the connection of the safety overflow, drain hose and lid

drain for leaks, free drainage and gradient.

▪ If necessary, clean the safety overflow and drain hose and relay

it; replace damaged parts.

INFORMATION

Thanks to its design, the indoor unit requires very little

maintenance. No corrosion protection equipment is re-

quired (such as expendable anodes). This means there is

no need for maintenance work such as changing the pro-

tective anodes or cleaning the inside of the storage tank.

8

Check the connection of the safety overflow and drain hose for

leaks, free drainage and gradient.

▪ If necessary, clean the safety overflow and drain hose and relay

it; replace damaged parts.

9

Check all electrical components, connections and cables.

▪ Repair damaged parts or replace them.

INFORMATION

If the connection cable of the optional backup heater is

damaged, the entire backup heater must be replaced.

The connection cable cannot be exchanged separately.

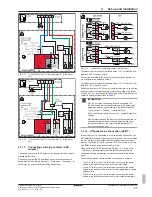

10

Check the water pressure of the cold water supply (<6 bar)

▪ and, if necessary, the fitting or adjustment of the pressure redu-

cer.

11

Check the system water pressure on the RoCon+ HP controller

of the indoor unit.

▪ If necessary, top up the water in the heating system until the

pressure display is in the permissible range (see

Chap. 7.2.2

).

12

Check and clean the filter/sludge separator.

13

Check the minimum flow (see

Chap. 5.1.4

).

14

Clean the plastic surface of the indoor unit with soft cloths and

mild detergent. Do not use any cleaners with aggressive

solvents (damage to the plastic surface may occur).

15

Re-install the cover (see

Chap. 4.4.2

).

16

Perform maintenance on the outdoor unit and other heating

components connected to the indoor unit according to the re-

spective installation and operating instructions.

17

Complete the record of maintenance in the operating manual of

the indoor unit provided.

7.2

Inspection and maintenance tasks

Cleaning the protective cover and storage tank

▪ The low-maintenance plastic only needs to be cleaned with soft

cloths and mild detergent.

▪ Do not use any cleaners with aggressive solvents (damage to the

plastic surface may occur).

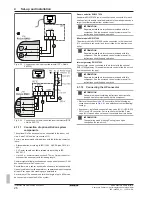

7.2.1

Filling, topping up the storage tank

CAUTION

Filling the storage tank with too high a water pressure or

too high a flow speed can cause damage to the indoor unit.

▪ Only fill with a water pressure <6 bar and a flow speed

<15 l/min.

Summary of Contents for Altherma 3 ECH2O

Page 2: ......