4 Piping installation

Installation manual

10

EGSAH/X06+10DA9W(G)

Daikin Altherma 3 GEO

4P569811-1 – 2019.02

4.2.2

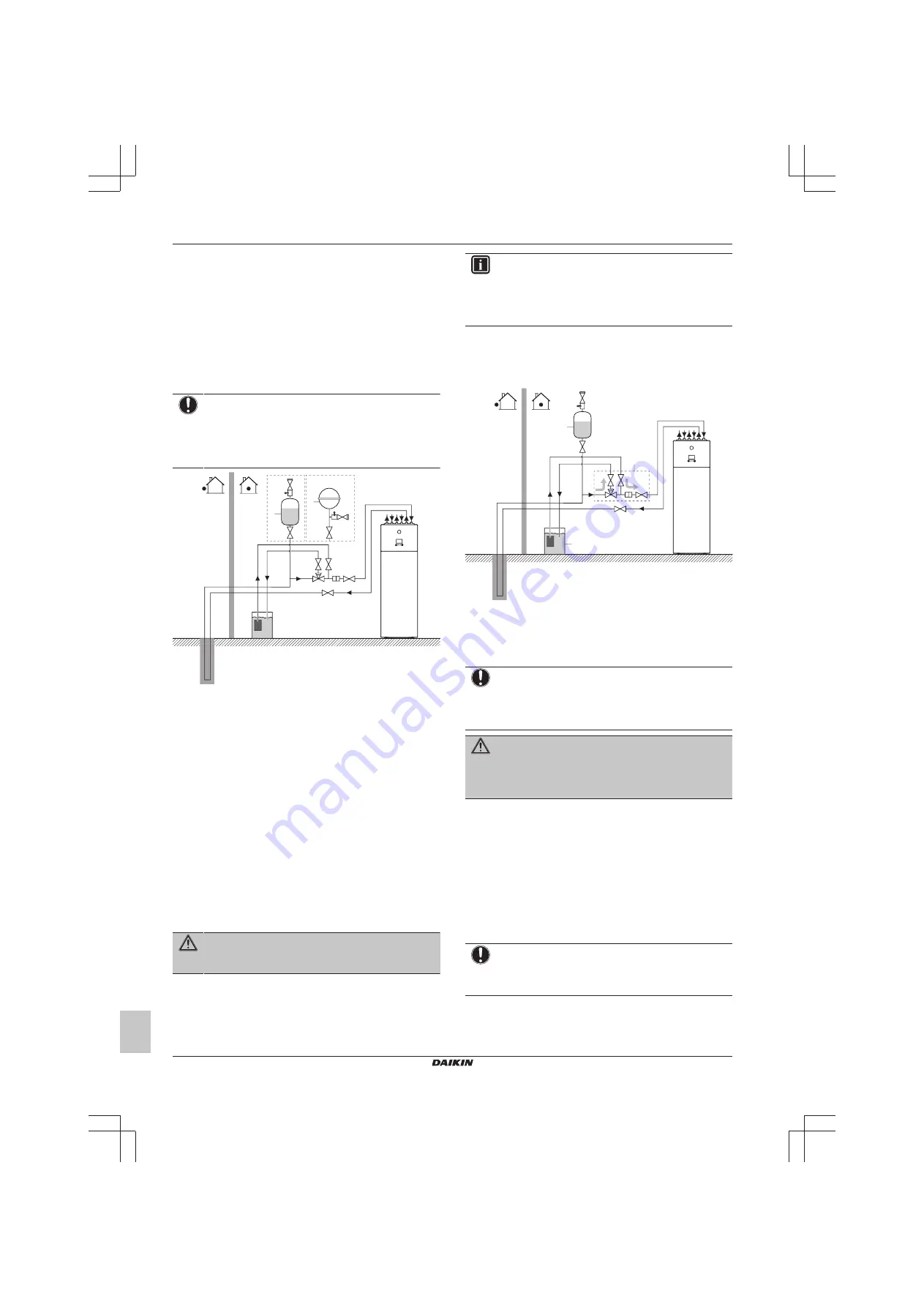

To connect the brine level vessel

The brine level vessel (delivered as accessory) must be installed on

the brine side of the heat pump system. A safety valve is included

with the vessel. The vessel serves as a visual indicator of the brine

level of the system. Air trapped in the system is collected by the

vessel, causing the level of brine in the vessel to decrease.

1

Install the brine level vessel as the highest point in the brine

circuit on the entering brine piping.

2

Mount the included safety valve on top of the vessel.

3

Install a shut-off valve (field supplied) below the vessel.

NOTICE

If it is not possible to install the brine level vessel as the

highest point in the circuit, install an expansion vessel (field

supply) and install the safety valve in front of the expansion

vessel. Failure to observe this instruction may result in

malfunctioning of the unit.

a

b

a

Brine level vessel (accessory)

b

Expansion vessel (field supply, in case brine level vessel

cannot be installed as the highest point)

If the level of brine in the vessel is lower than 1/3, fill the vessel with

brine:

4

Close the shut-off valve below the vessel.

5

Remove the safety valve on top of the vessel.

6

Top up the vessel with brine until it is approximately 2/3 filled.

7

Reconnect the safety valve.

8

Open the shut-off valve below the vessel.

4.2.3

To connect the brine filling kit

A brine filling kit (field supply or option kit KGSFILL2) can be used to

flush, fill and drain the brine circuit of the system.

For installation instructions, see the installation manual of the brine

filling kit.

4.2.4

To fill the brine circuit

WARNING

Before, during and after filling carefully check the brine

circuit for leakage.

INFORMATION

The materials used in the brine circuit of the unit are

chemically resistant to the following anti-freeze fluids:

▪ 40 mass% propylene glycol

▪ 29 mass% ethanol

1

Install the brine filling kit. See

"4.2.3 To connect the brine filling

2

Connect a field supplied brine filling system to the 3-way valve.

3

Position the 3‑way valve correctly.

a

c

b

a

Brine level vessel (accessory)

b

Brine filling kit (field supply or option kit KGSFILL2)

c

Brine filling system (field supply)

4

Fill the circuit with brine until a pressure of ±2.0 bar (= 200 kPa).

5

Return the 3‑way valve to its original position.

NOTICE

A field supplied filling kit may come without a filter that

protects components in the brine circuit. In this case, it is

the responsibility of the installer to install a filter on the

brine side of the system.

WARNING

Temperature of the fluid running through the evaporator

can become negative. It MUST be protected against

freezing. For more information, see setting [A‑04] in

.

4.2.5

To insulate the brine piping

The piping in the complete brine circuit MUST be insulated to

prevent reduction of the heating capacity.

Consider that the brine circuit piping inside the house can/will

condensate. Foresee adequate insulation for these pipes.

4.3

Connecting the water piping

4.3.1

To connect the water piping

NOTICE

Do NOT use excessive force when connecting the piping.

Deformation of the piping can cause malfunctioning of the

unit.

1

Install the shut off-valve with integrated filter (delivered as

accessory) at the space heating/cooling water inlet.

2

Connect the space heating/cooling in pipe to the shut-off valve

and the space heating/cooling out pipe to the unit.

Summary of Contents for Altherma 3 GEO

Page 38: ......

Page 39: ......

Page 40: ...4P569811 1 2019 02 Copyright 2019 Daikin 4P569811 1 0000000S ...