7

|

Piping installation

Installer reference guide

76

EPRA14~W1 + ETVH/9W(G)

Daikin Altherma 3 H HT F

4P587502-1 – 2019.07

▪

Air vents.

Provide air vents at all high points of the system, which must also be

easily accessible for servicing. Two automatic air purges are provided in the

indoor unit. Check that the air purges are NOT tightened too much, so that

automatic release of air in the water circuit is possible.

▪

Zn-coated parts.

Never use zinc coated parts in the water circuit. Because the

internal water circuit of the unit uses copper piping, excessive corrosion may

occur.

▪

Non-brass metallic piping.

When using non-brass metallic piping, insulate the

brass and non-brass properly so that they do NOT make contact with each other.

This to prevent galvanic corrosion.

▪

Valve – Change‑over time.

When using a 2-way valve or a 3-way valve in the

water circuit, the maximum change-over time of the valve must be 60 seconds.

▪

Domestic hot water tank – Capacity.

To avoid stagnation of water, it is

important that the storage capacity of the domestic hot water tank meets the

daily consumption of domestic hot water.

▪

Domestic hot water tank – After installation.

Immediately after installation, the

domestic hot water tank must be flushed with fresh water. This procedure must

be repeated at least once a day the first 5 consecutive days after installation.

▪

Domestic hot water tank – Standstills.

In cases where during longer periods of

time there is no consumption of hot water, the equipment MUST be flushed with

fresh water before usage.

▪

Domestic hot water tank – Disinfection.

For the disinfection function of the

domestic hot water tank, see

163].

▪

Thermostatic mixing valves.

In accordance with the applicable legislation, it may

be necessary to install thermostatic mixing valves.

▪

Hygienic measures.

The installation must be in compliance with the applicable

legislation and may require additional hygienic installation measures.

▪

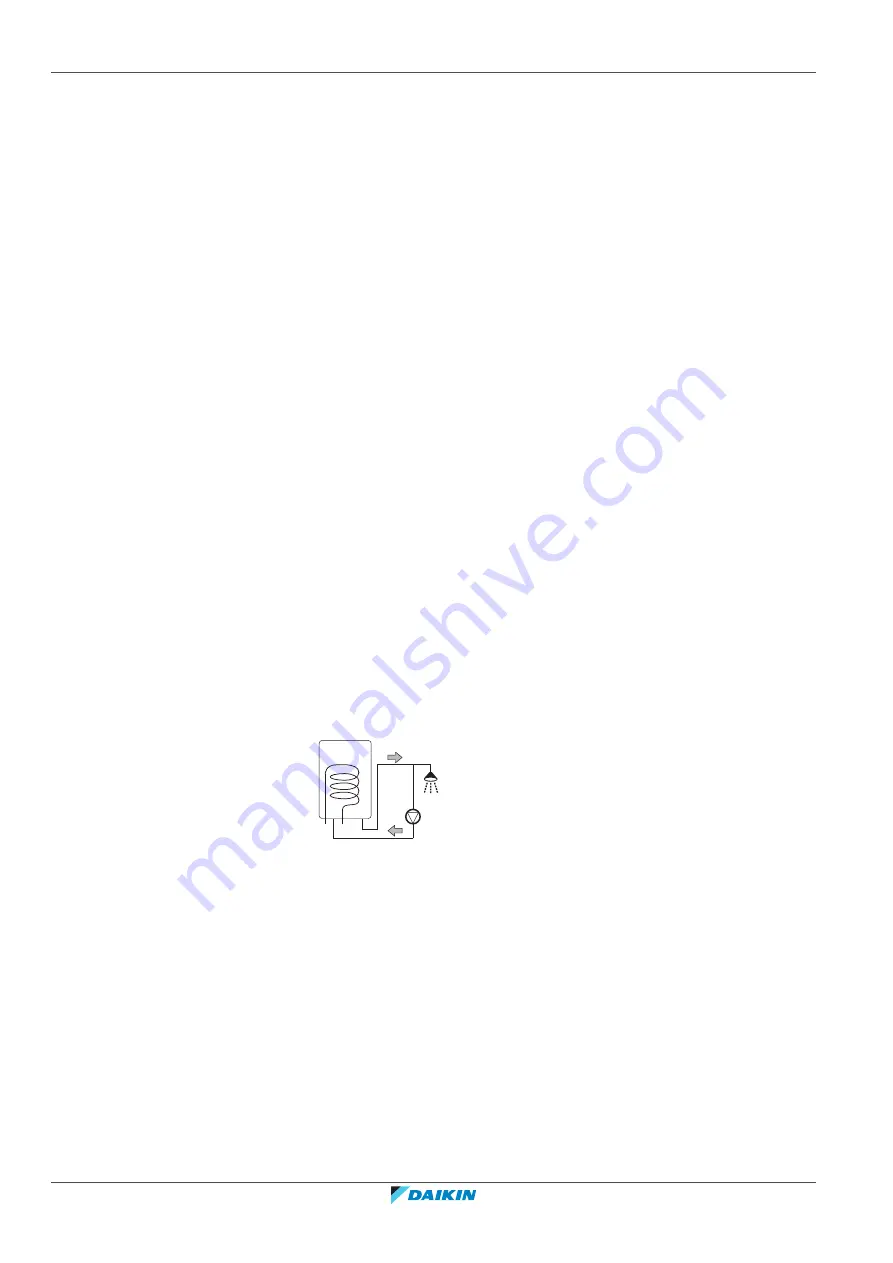

Recirculation pump.

In accordance with the applicable legislation, it may be

required to connect a recirculation pump in between the hot water end point

and the recirculation connection of the domestic hot water tank.

c

d

a

b

a

Recirculation connection

b

Hot water connection

c

Shower

d

Recirculation pump

7.1.2 Formula to calculate the expansion vessel pre-pressure

The pre-pressure (Pg) of the vessel depends on the installation height difference

(H):

Pg=0.3+(H/10) (bar)

7.1.3 To check the water volume and flow rate

The indoor unit has an expansion vessel of 10 litre with a factory-set pre-pressure

of 1 bar.

To make sure that the unit operates properly: