6 Configuration

Installation manual

19

ETVH/9W(G)

Daikin Altherma 3 H HT F

4P586454-1 – 2019.07

#

Code

Description

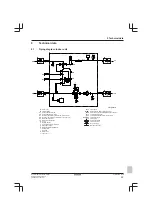

[4.4]

[7‑02]

▪ 0:

Single zone

Only one leaving water temperature

zone:

a

a

Main LWT zone

[4.4]

[7‑02]

▪ 1:

Dual zone

Two leaving water temperature zones.

The main leaving water temperature

zone consists of the higher load heat

emitters and a mixing station to

achieve the desired leaving water

temperature. In heating:

b

c

a

a

Additional LWT zone: Highest

temperature

b

Main LWT zone: Lowest temperature

c

Mixing station

CAUTION

If there are 2 zones, it is important that the zone with the

lowest water temperature is configured as the main zone,

and the zone with the highest water temperature is

configured as the additional zone. Not configuring the

system in this way could cause damage to the heat

emitters.

CAUTION

If there are 2 zones and the emitter types are wrongly

configured, water of high temperature can be sent towards

a low temperature emitter (underfloor heating). To avoid

this:

▪ Install an aquastat/thermostatic valve to avoid too high

temperatures towards a low temperature emitter.

▪ Make sure you set the emitter types for the main zone

[2.7] and for the additional zone [3.7] correctly in

accordance with the connected emitter.

NOTICE

An overpressure bypass valve can be integrated in the

system. Keep in mind that this valve might not be shown

on the illustrations.

Glycol Filled system

This setting gives the installer the possibility to indicate whether the

system is filled with glycol or water. This is important in case glycol is

used to protect the water circuit against freezing. If NOT set

correctly, the liquid in the piping can freeze.

#

Code

Description

N/A

[E-0D]

Glycol Filled system

: Is the system

filled with glycol?

▪ 0:

No

▪ 1:

Yes

6.2.4

Configuration wizard: Backup heater

The backup heater is adapted to be connected to most common

European electricity grids. If the backup heater is available, the

voltage, configuration and capacity must be set on the user

interface.

The capacities for the different steps of the backup heater must be

set for the energy metering and/or power consumption control

feature to work properly. When measuring the resistance value of

each heater, you can set the exact heater capacity and this will lead

to more accurate energy data.

Voltage

▪ For a

6V

model, this can be set to:

▪

230V, 1ph

▪

230V, 3ph

▪ For a

9W

model, this is fixed to

400V, 3ph

.

#

Code

Description

[9.3.2]

[5‑0D]

▪ 0:

230V, 1ph

▪ 1:

230V, 3ph

▪ 2:

400V, 3ph

Configuration

The backup heater can be configured in different ways. It can be

chosen to have a 1-step only backup heater or a backup heater with

2 steps. If 2 steps, the capacity of the second step depends on this

setting. It can also be chosen to have a higher capacity of the

second step in emergency.

#

Code

Description

[9.3.3]

[4‑0A]

▪ 0: Relay 1

▪ 1: Relay 1 / Relay 1+2

▪ 2: Relay 1 / Relay 2

▪ 3: Relay 1 / Relay 2

Emergency

Relay

1+2

INFORMATION

Settings [9.3.3] and [9.3.5] are linked. Changing one

setting influences the other. If you change one, check if the

other is still as expected.

INFORMATION

During normal operation, the capacity of the second step of

the backup heater at nominal voltage is equal to

[6‑03]+[6‑04].

INFORMATION

If [4‑0A]=3 and emergency mode is active, the power

usage of the backup heater is maximal and equal to

2×[6‑03]+[6‑04].

INFORMATION

Only for systems with integrated domestic hot water tank: If

the storage temperature set point is higher than 50°C,

Daikin recommends NOT to disable the backup heater

second step because it will have a big impact on the

required time for the unit to heat up the domestic hot water

tank.

Summary of Contents for Altherma 3 H HT F Series

Page 33: ......

Page 34: ......

Page 35: ......

Page 36: ...4P586454 1 2019 07 Copyright 2019 Daikin 4P586454 1 0000000U...