5 Electrical installation

Installation manual

11

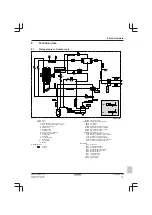

EPRA14~W1

Daikin Altherma 3 H HT

4P586100-1 – 2019.07

The Hydronic Piping Calculation tool also calculates the maximum

hydronic piping length from the indoor unit to the outdoor unit based

on the emitter pressure drop or the other way around.

The Hydronic Piping Calculation tool is part of the Heating Solutions

Navigator

which

can

be

reached

via

professional.standbyme.daikin.eu

Please contact your dealer if you have no access to Heating

Solutions Navigator.

This recommendation ensures good operation of the unit, however,

local regulations may differ and shall be followed.

5

Electrical installation

DANGER: RISK OF ELECTROCUTION

WARNING

Rotating fan.

Before powering ON or servicing the outdoor

unit, make sure that the discharge grille covers the fan as

protection against a rotating fan. See:

▪

"6.2 To install the discharge grille" on page 14

▪

"6.3 To remove the discharge grille, and put the grille in

safety position" on page 15

WARNING

ALWAYS use multicore cable for power supply cables.

CAUTION

Do NOT push or place redundant cable length in the unit.

NOTICE

The distance between the high voltage and low voltage

cables should be at least 50 mm.

5.1

About electrical compliance

Only for EPRA14~18DAV3

Equipment complying with EN/IEC 61000‑3‑12 (European/

International Technical Standard setting the limits for harmonic

currents produced by equipment connected to public low-voltage

systems with input current >16 A and ≤75 A per phase.).

5.2

Guidelines when connecting the

electrical wiring

Tightening torques

Item

Tightening torque (N•m)

M4 (X1M, X2M)

1.2~1.5

M4 (earth)

5.3

To connect the electrical wiring on

the outdoor unit

1

Open the switch box cover. See

.

2

Insert the cables at the back of the unit, and route them through

the factory-mounted cable sleeves into the switch box. For the

power supply, use the factory-mounted cable.

d

c2

b2

c1

b1

a1

a2

a1+a2

Power supply cable (factory-mounted cable)

b1+b2

Interconnection cable (field supply)

c1+c2

(optional) Drain tube heater cable (field supply)

d

Cable sleeves (factory-mounted)

3

Inside the switch box, connect the wires to the appropriate

terminals, and fix the cables with cable ties. See:

▪

"5.3.1 In case of V3 models" on page 11

▪

"5.3.2 In case of W1 models" on page 12

5.3.1

In case of V3 models

1

Power supply cable

:

▪ Use the factory-mounted cable, which is already routed

through the frame.

▪ Connect the wires to the terminal block.

▪ Fix the cable with a cable tie.

Use the factory-mounted cable.

Wires: 1N+GND

Maximum running current: Refer to name plate on unit.

—

L N PE

b

a

L

N