Page 12 of 60

IM 817-4

8"

(203mm)

14"

(356mm)

21"

(533mm)

5"

(127 mm)

5" (127 mm)

2-7/16"

(62 mm)

7-1/4" (184 mm)

13"

(330mm)

6-1/2"

(165mm)

7" (178 mm)

1" (25 mm)

Before Setting the Unit in Place

Move the unit ventilator to the correct location. See Table 2, page 6

for approximate shipping weights.

Carefully remove unit ventilator from wood skid. Be sure to properly

dispose of the skid in accordance with local recycling rules and

guidelines.

Removing Unit from the Skid

Remove fasteners at each end which hold the unit to the skid and

carefully slide the front of the unit off the skid (1). Tip unit forward

until the bottom of the slotted front kickplate is resting on the floor (2).

Lift rear of unit off of the skid by tipping unit forward while supporting

the unit from the front, until it is possible to slide skid out from under

the unit. GENTLY LOWER the rear of the unit to the floor (3).

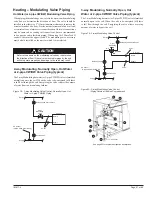

Figure 26 - Front View with End Panels - Mounting Holes Locations

Mounting Holes

Figure 27 - Rear View without End Panels and Subbase - Piping and

Electrical Knockout Locations and Dimensions

Knockout Opening Between Pipe

Tunnel & End Compartment.

Rear Entry Area or Draftstop

Opening Knockouts

Outdoor Air Intake Opening

End compartment Draftstop knockouts must be removed for

proper Draftstop operation. (21-7/8" units only)

Size S07 = 48" (1219mm)

Size S10 = 60" (1524mm)

Size S13 = 72" (1828mm)

Size S15 = 84" (2133mm)

Note:

See Draftstop IM bulletin (IM 473) for suggested installation procedure.

Leakage of outdoor air wastes energy, causes drafts and erratic

unit ventilator operation. Check the following details: At the correct

unit ventilator location, examine the wall surface. Make sure that

it is smooth, plumb, and perpendicular to the floor. The seals on

the rear of the unit ventilator will take up the small irregularities

found in normal masonry construction. If the wall is irregular

or has mullions, install furring strips to provide a flush surface

against which the unit ventilator can seal. If there are moldings

on the floor/wall line, omit them behind the unit ventilator. Provide

a sealing surface at the floor line. Install a seal pad under the

unit to prevent air leakage. Install the unit ventilator against a

wall made of non-combustible material, and on a floor made of

non-combustible material. Floor must be level, unbroken and

structurally strong to support the unit.

Aluminum Wall Louver

Assembly with Bird Screen

(See Note 1)

3'' (76mm)

VentiMatic

Shutter

Assembly

Center Cover

10

3

⁄

8

"

(264mm)

Figure 24 - Two VentiMatic Shutters & Wall Louver

B

(see table 3,

page 10)

Outside

Decorative Exterior Grille Also Available (See Note 2, page 11)

(Bird Screen not shown)

Figure 25 - Removing Unit from Skid

1. Carefully slide the front of the unit off the front of the skid.

2. While supporting unit from the front, slowly tip unit forward until bot-

tom of kickplate is resting on floor. Lift skid slightly and GENTLY lower

the rear of the unit to the floor while pulling skid back (DO NOT LET

THE UNIT DROP).

Tip forward until kick

-

plate rests on floor

Kickplate

Approx. 10"

Mounting Holes, Piping and Electrical

Knockout Locations & Dimensions

CAUTION

NOTICE