Page 6 of 60

IM 817-4

Models

Shipping Weight

Approx. Shipping

Filter Size

Unit Length*

Number

AVS, AVV,

lbs. (kg)

Weight lbs. (kg)

in. (mm)

in. (mm)

of Fans

AVR, AVB

16

5

/

8

"Units 21

7

/

8

"Units

S07

350 (168)

370 (163)

10 x 36.5 x 1

62 (1575)

2

(254 x 927 x 25)

S10

425 (193)

445 (202)

10 x 48.5 x 1

74 (1880)

3

(254 x 1232 x 25)

S13

495 (225)

525 (238)

10 x 60.5 x 1

86 (2174)

4

(254 x 1551 x 25)

S15

570 (259)

600 (272)

Two: 10 x 36.5 x 1

98 (2489)

4

(254 x 927 x 25)

Disconnect all electrical power before servicing unit.

Electrical shock will cause severe injury or death.

Hazardous Voltage!

Use copper conductors only. Unit terminals are not designed to

accept other types of conductors. Failure to do so may cause

damage to the equipment.

Personal injury hazard. Wear protective gloves to avoid possible

cuts and abrasions from exposed edges. Avoid contact with sharp

edges.

Cleaning agents may cause serious damage to internal

components, such as aluminum coils and electronic controls,

etc. Do not operate unit ventilator while building maintenance

cleaning agents are in use.

Pre-Installation Considerations

Properly Identify Unit Ventilator(s)

To be sure the correct unit ventilator(s) is/are installed in the

correct location(s), the installer must check the packing list and unit

identification/tagging number(s) against the plans.

Further, the unit data

plate, (see figure 1) located on the lower right end of the unit ventilator,

contains specific information of standard components as listed in Table 1.

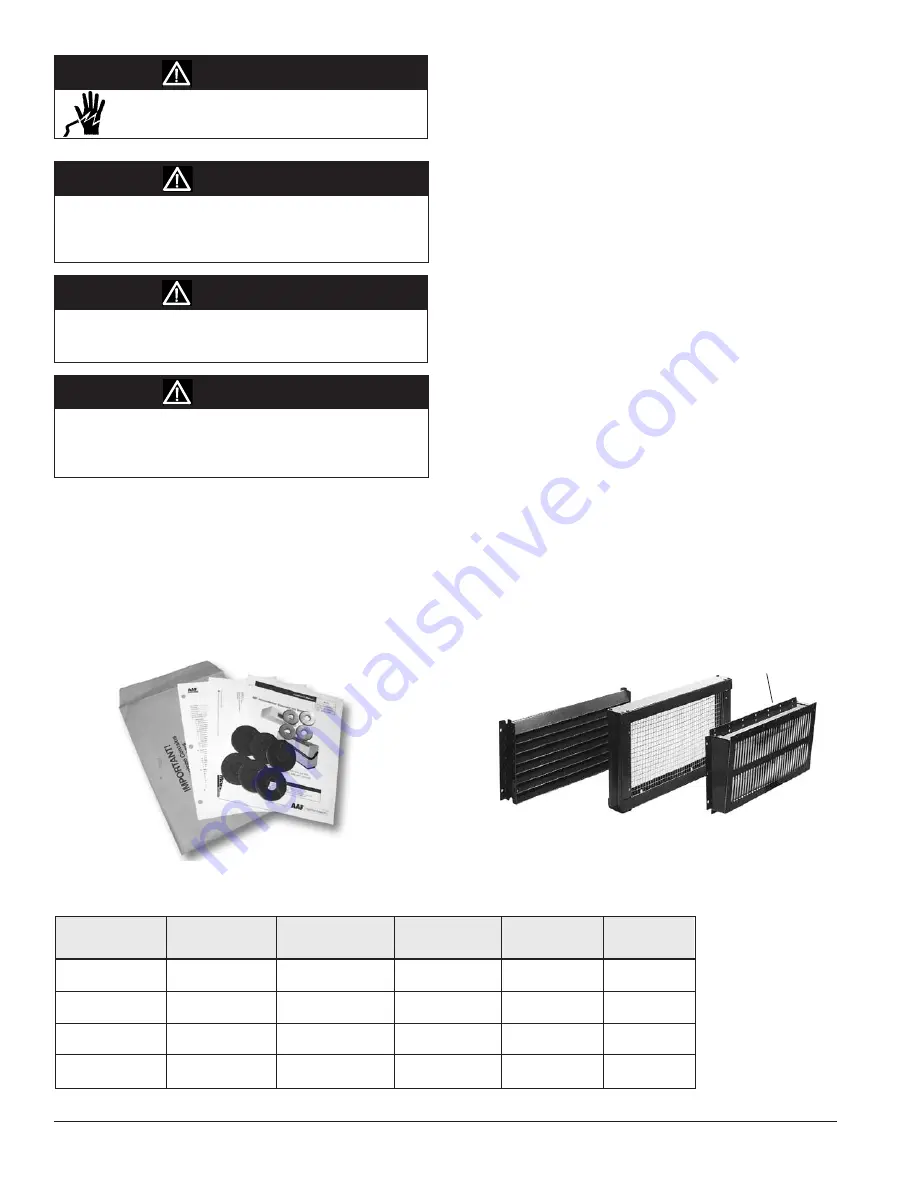

Figure 4 - Shipping Envelope Contents - Located in right end

compartment of unit.

Uncrate and Inspect the Unit Ventilator(s)

Carefully remove the packaging, remaining alert to any signs of shipping

damage. Be careful not to discard components that may be included with

the packaging. (You may want to retain some or all of the packaging

to provide jobsite unit location information and temporary protection

for the unit ventilator after installation.) Be sure to dispose of plastic

packaging and protective cardboard properly, in accordance with local

recycling rules and guidelines.

If unit is damaged, file a claim with the carrier. Notify the local Daikin

Unit Ventilator representative immediately.

Wall Openings, Louvers, and VentiMatic™

Shutter

Prior to unit installation, be sure that the exterior wall openings and

louvers, as applicable, are ready and in accordance with the job plans.

Vertical Floor Models AVS, AVV, AVB, AVR are typically installed

in front of a wall opening containing a properly sized louver that is

designed to let in outside air while preventing water (such as rain) from

getting past the louver and into the unit itself. A weather-tight seal keeps

unwanted air and moisture from entering the occupied space. See Figures

6 through 21, and table 1 for various louver details.

VentiMatic

™

Shutter Assembly

In many installations, a Daikin VentiMatic Shutter Assembly is specified.

See figure 5. This one-way shutter is a continuously variable, gravity

actuated, room exhaust vent that operates in direct response to positive

static pressure. It opposes any airflow into the room and allows a slight

positive pressure.

It is important that the VentiMatic shutter and unit ventilator louvers

are mounted on the same wall. This neutralizes the effect of the wind.

Forcing excess air into the room through the unit ventilator louver

overcomes the same wind pressure that works to keep the VentiMatic

shutter closed. This prevents room air exhausting from the room through

the VentiMatic shutter.

Note: Birdscreen and louver are shipped in one (1) piece.

Figure 5 – VentiMatic Shutter Assembly

Outside

Louver

VentiMatic Shutter

Roomside

Relief Air

Table 2 - Approximate Shipping Weights, Physical Data

* Measurement is without end panels. All unit ventilators are 30" (762 mm) high.

DANGER

WARNING

CAUTION

WARNING